Red mycelium protein feed and a preparation method thereof

A technology of mycelium protein and feed, applied in animal feed, animal feed, climate change adaptation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

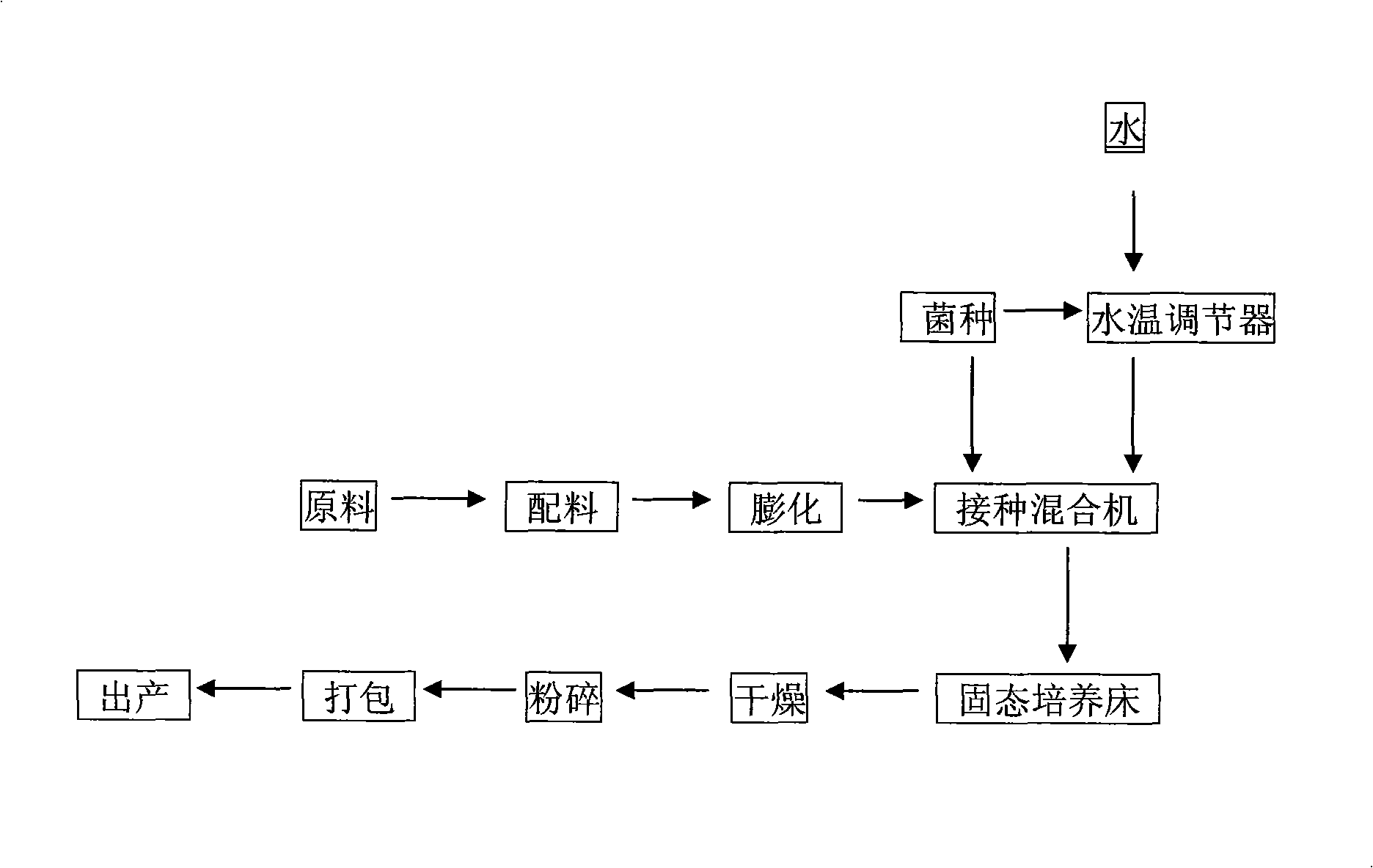

[0029] As shown in the accompanying drawings, the preparation method of the red mycelium protein feed of the present invention includes the following steps: mixing ingredients of raw materials, puffing, inoculation, solid-state culture, drying, crushing, and packaging;

[0030] The preparation steps of the method are as follows:

[0031] Step 1: According to the carbon and nitrogen ratio of 1: 20 to 80 ingredients, take corn, rice, millet, wheat bran, rice

[0032] A total of 80-100 parts of beans, soybean meal and peanut bran are mixed evenly;

[0033] Step 2: Put the mixed material into the feed extruder for puffing, and the puffing temperature is 150℃~180℃;

[0034] Step 3: Inoculation, put the extruded material into the feed mixer, and add 0.10 to 0.15 parts of bacteria in proportion

[0035] seed, then add 30-40 parts of water at 25°C to 55°C, stir well, and mix evenly.

[0036] The coefficient of variation CV<10%, adjust the mixed material by adjusting the water tempe...

Embodiment

[0042] Step 1: According to the carbon and nitrogen ratio of 1:50, take 50% of rice, 30% of wheat husk, and 20% of soybean meal in a total of 100 parts by weight, and mix them evenly;

[0043] Step 2: Put the mixed material into the feed extruder for extruding, and set the extruding temperature to 160°C;

[0044] Step 3: Inoculation, put the extruded material into the feed mixer, add 0.10 part of B. trispora species in proportion, and then add 40 parts of warm water at 40°C, stir well, and the coefficient of variation of mixing uniformity CV < 10%, adjust the mixed material by adjusting the water temperature, and keep the material temperature at 25℃~38℃;

[0045] Step 4: cultivating and multiplying, putting the evenly mixed materials into the culture room, the indoor air temperature is controlled at 30°C, the air humidity is controlled within the range of 80-90%, and the culture time is 35 hours;

[0046] Step 5: Use an airflow dryer to dry the cultured and propagated materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com