Resin convex mould for relief printing and method for producing organic EL elements using the same

A letterpress printing and resin technology, which is applied in the field of organic EL element manufacturing, can solve the problems of low solubility, high polymer swelling, and reduced dimensional accuracy, achieving small damage, stable dimensional accuracy, and no damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Next, examples will be described.

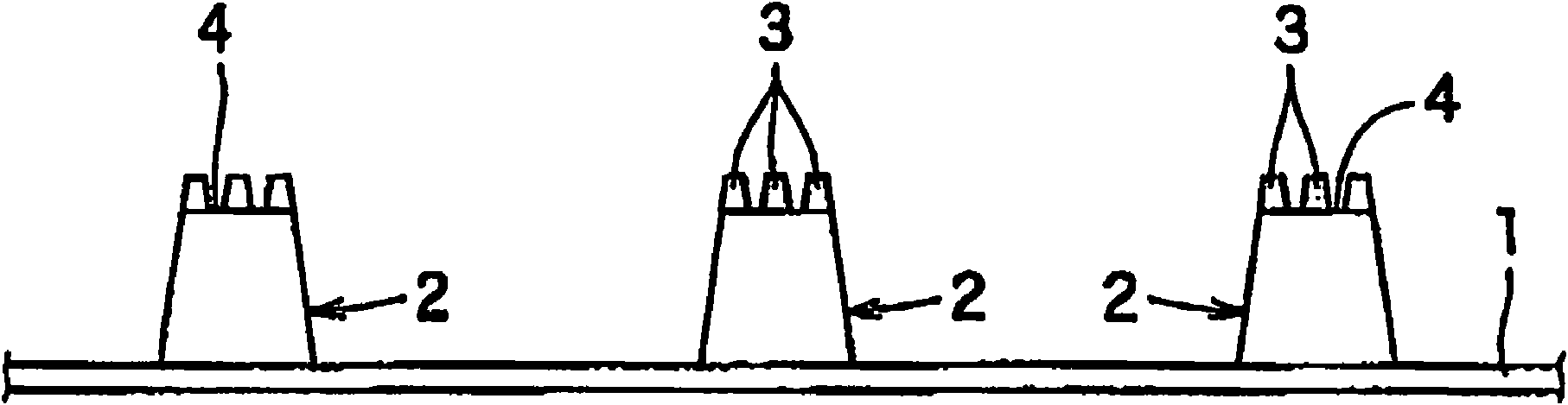

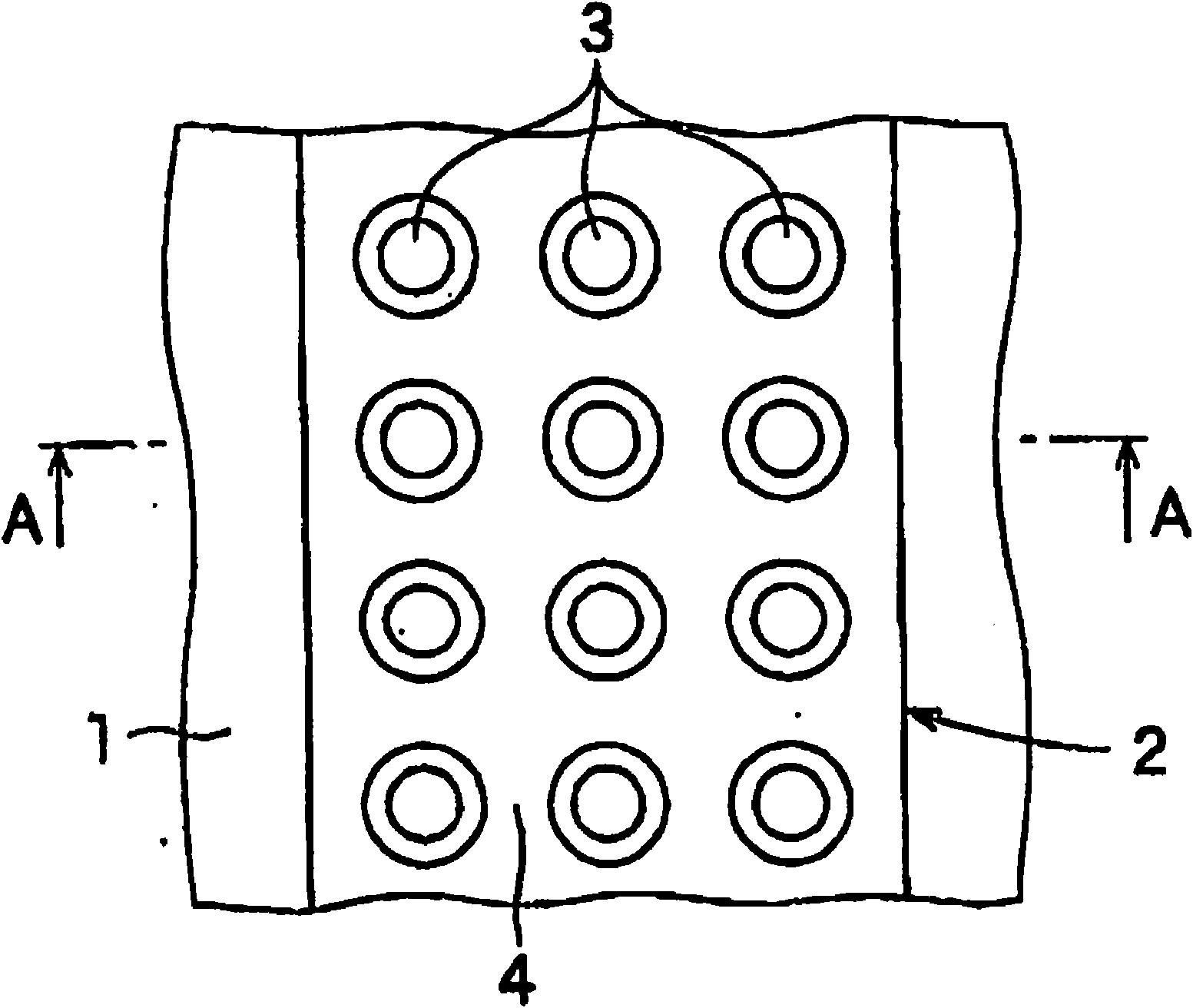

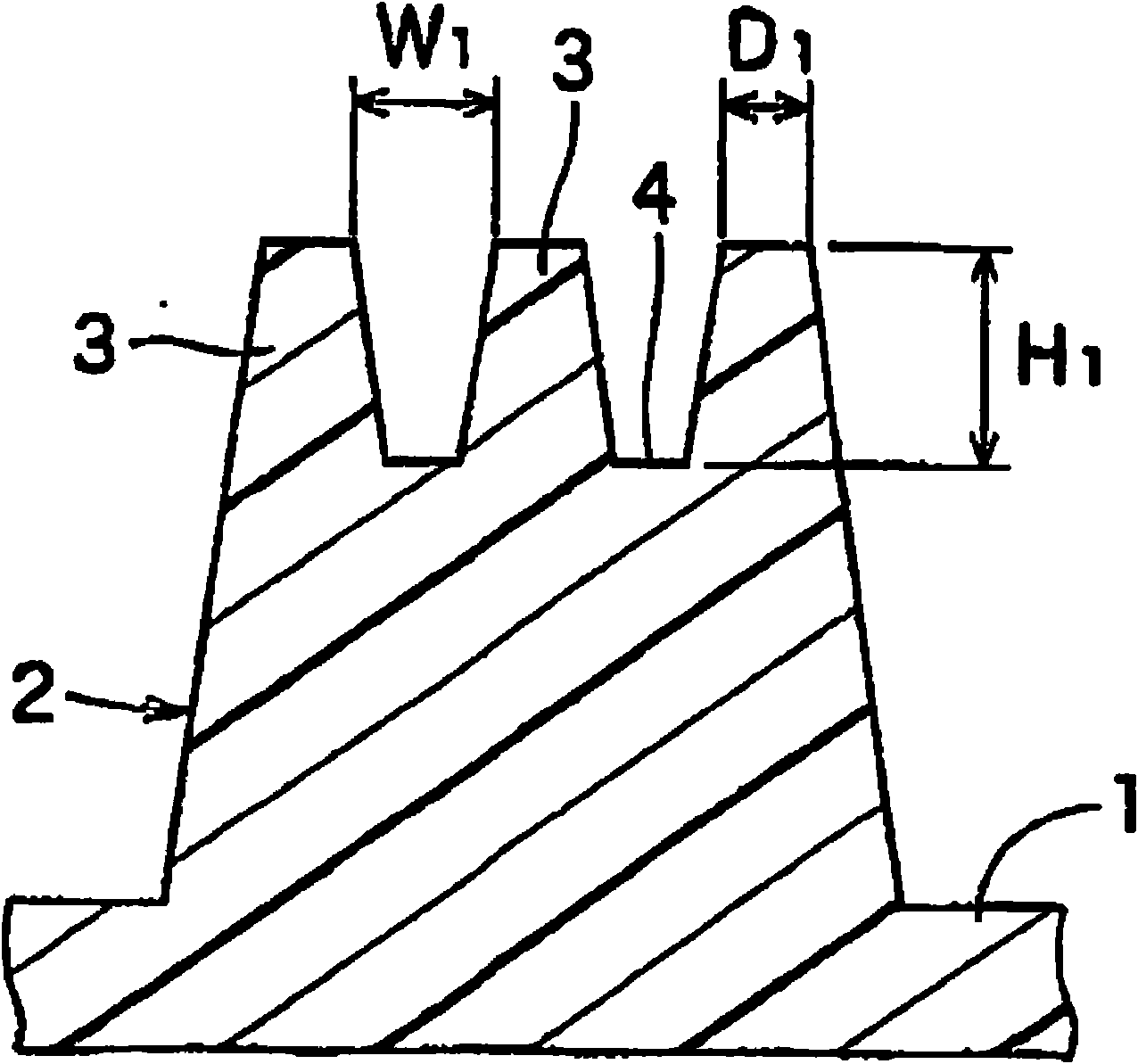

[0051] Prepare Figure 1 ~ Figure 3 Resin relief of the structure shown. The JIS rubber hardness of the resin relief plate was Shore A 85°, and the weight change rate of the resin relief plate was 5% when continuously immersed in anisole at a room temperature of 23° C. for 24 hours. This resin relief plate was produced using the plate materials shown in Table 1 below in the same manner as the above-mentioned resin relief plate. The total thickness of the plate was 1.3 mm, and the thickness of the substrate was 0.7 mm.

[0052] Table 1

[0053] The total thickness of the plate

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com