Method for preparing methylbenzene or dimethylbenzene by alkylating benzene with methanol

A xylene and alkylation technology, applied in chemical instruments and methods, organic chemistry, molecular sieve catalysts, etc., can solve the problems of low efficiency and no teaching of desulfurization technology, and achieve the effect of convenient adjustment and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

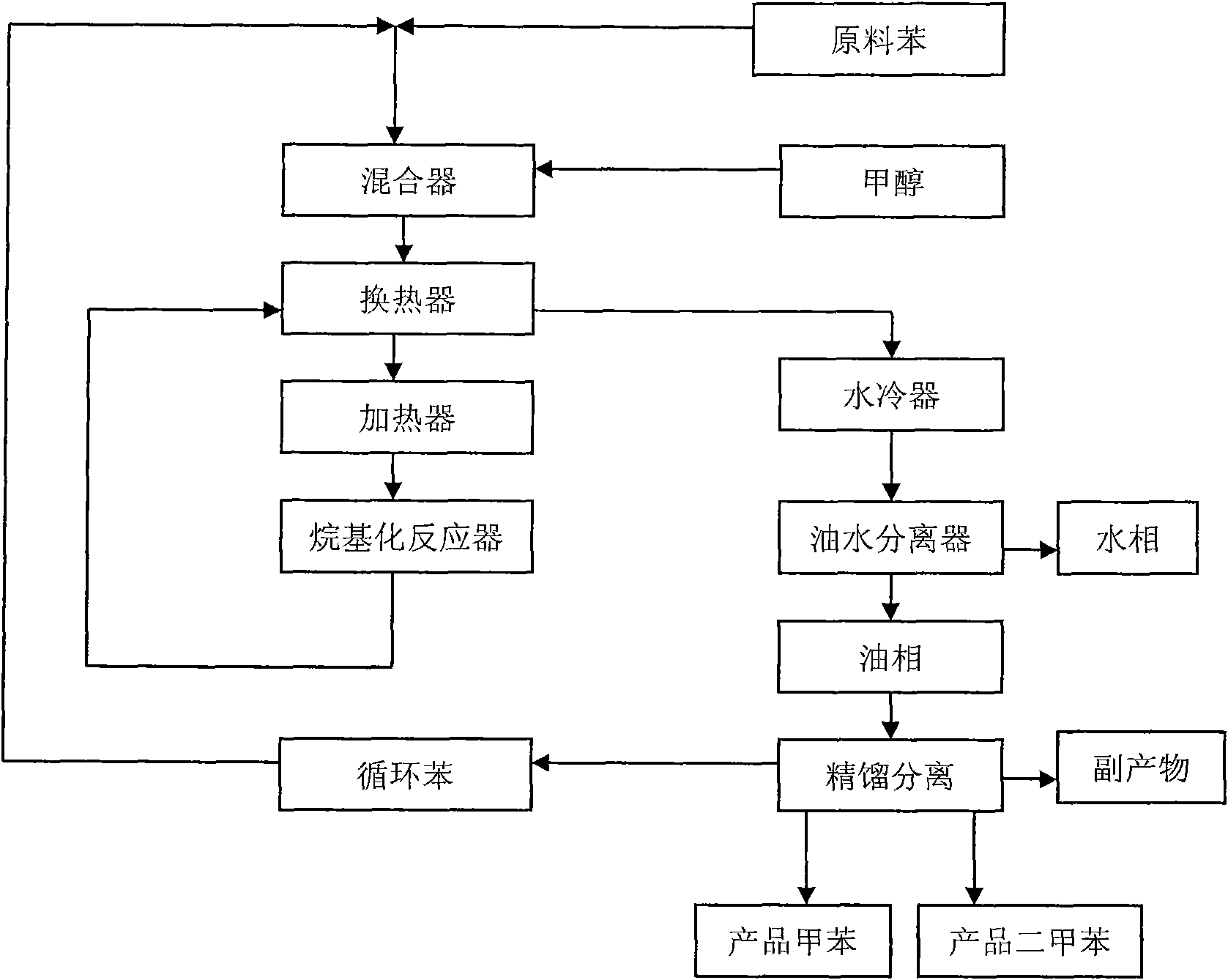

Image

Examples

Embodiment 1

[0033] Install a small-scale fixed-bed methanol and benzene alkylation test device to produce toluene and xylene according to the flow chart of the attached drawing. All reaction devices are made of stainless steel. In an alkylation reactor with an inner diameter of 6 mm, 10 ml of molecular sieve catalyst was filled, and the catalyst was exchanged HZSM-5 molecular sieve. The raw material benzene and the alkylating reagent methanol are respectively fed by micro metering pumps. Control the parameters of the alkylation reaction, collect and analyze the products, and calculate the reaction results. The different reaction parameters and reaction results are shown in Table 1.

[0034] Table 1 Example 1 process parameters and reaction results

[0035] serial number

Embodiment 2

[0037] With embodiment 1, change benzene alcohol molar ratio, the reaction result that obtains is shown in Table 2.

[0038] Table 2 embodiment 2 process parameter and reaction result (benzyl alcohol mol ratio changes)

[0039] serial number

Embodiment 3

[0041] With embodiment 1, change reaction temperature, the reaction result that obtains is shown in Table 3.

[0042] Table 3 Example 3 process parameters and reaction results

[0043] serial number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com