Industrialized cleaning production process of captan

A technology for cleaner production and sterilization, applied in the field of pesticides, can solve the problems of workers being unable to operate, increasing production costs, harming human health, etc., and achieving the effect of simple operation process and process method, safe and reliable production process, and reduction of three waste discharges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

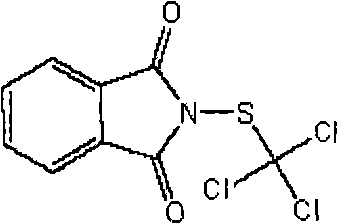

Image

Examples

Embodiment 1

[0014] Add 150 milliliters of water to a 250 milliliter four-necked bottle equipped with a stirrer, a thermometer and a dropping device. Add 8.3 grams (content 96.0%) sodium hydroxide and 30.0 grams phthalimide (content 98.0wt%) and catalyst benzyltriethylammonium chloride after starting to stir, dissolve 0.5 hour, then mix mixture in 4 37.5 g (content 98.0 wt%) of trichlorothiochloromethane was added dropwise at ℃, and the reaction was kept for 2.0 hours. If the reaction material turned sour, it indicated that the reaction was over. Transfer the material to a purification and temperature-raising treatment kettle, heat up to 50-60°C, keep the temperature for 3.0 hours, then cool down to 20°C and filter, wash the filter cake twice with 20 ml of water, and dry to obtain the light yellow white non-flammable powder Setting solid powder. Yield 89.8%; content 97.1% (quantitative by external standard method of Japan Shimadzu high performance liquid chromatography; standard substance...

Embodiment 2

[0016] The temperature of the purified heat treatment of the reacted material in Example 1 is increased from 50-60° C. to 70-80° C., and the other conditions remain unchanged, so as to obtain the original drug of fendan. The yield is 88.5%, the content is 96.9 wt%, the content of phthalimide is 0.65 wt%, the content of trichlorothiochloromethane is less than 0.01 wt%, and the content of sodium chloride is 0.18 wt%. (detection method is with embodiment 1)

Embodiment 3

[0018] The material reacted in Example 1 is purified and heat-treated at 50-60° C. to 90-100° C., kept for 2.0 hours, and other conditions remain unchanged, to obtain the sterilized elixir. The yield is 89.3%, the content is 97.02wt%, the content of trichlorothiochloromethane is less than 0.01wt%, the content of phthalimide is 0.55wt%, and the content of sodium chloride is 0.2wt%. (detection method is with embodiment 1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com