2-3GHz band microstrip antenna with negative permeability material

A technology of negative magnetic permeability materials and microstrip antennas, which is applied to antennas, antenna arrays, and structural forms of radiating elements, can solve problems such as poor directivity, low gain, and low radiation efficiency of ordinary microstrip antennas, and achieve a simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

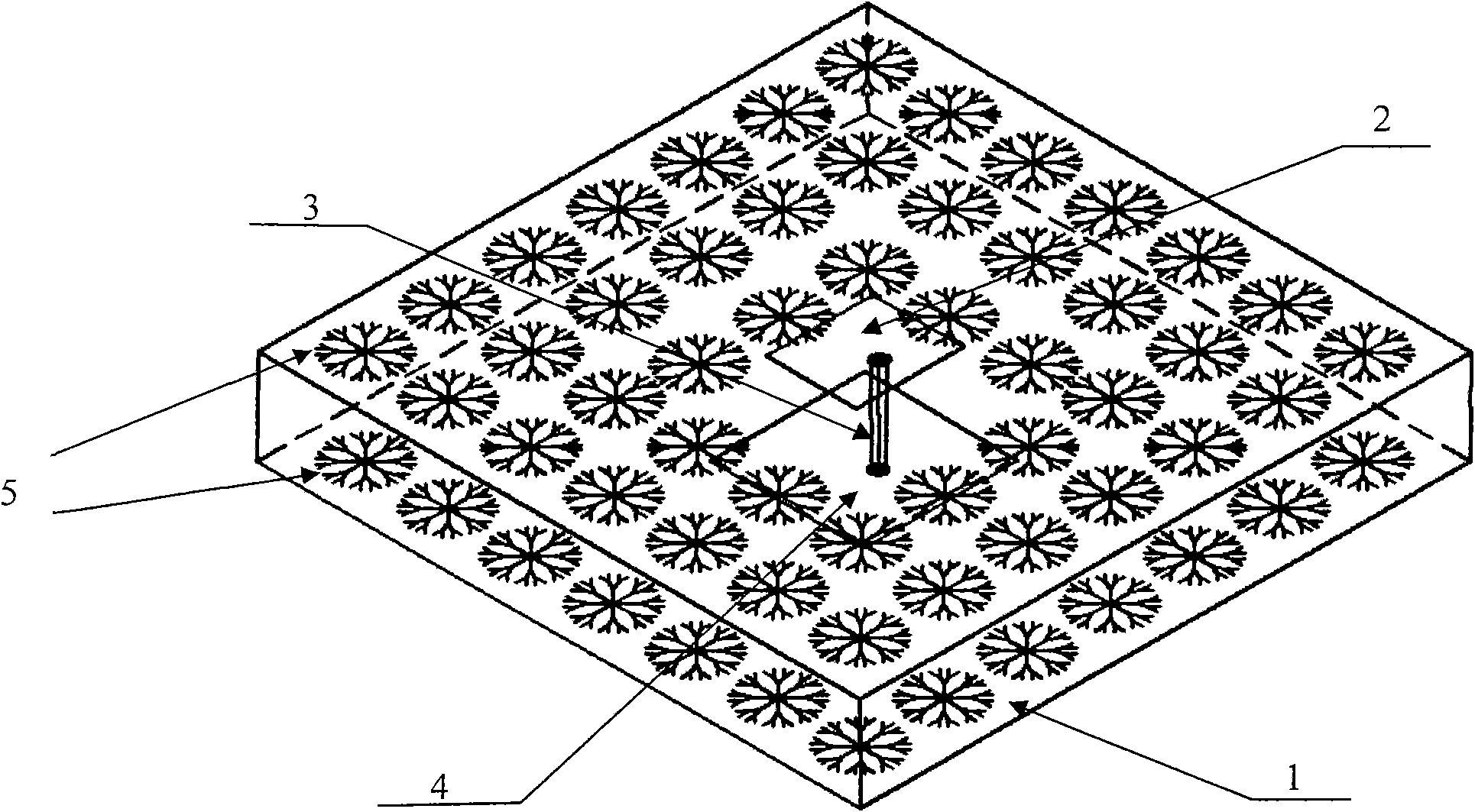

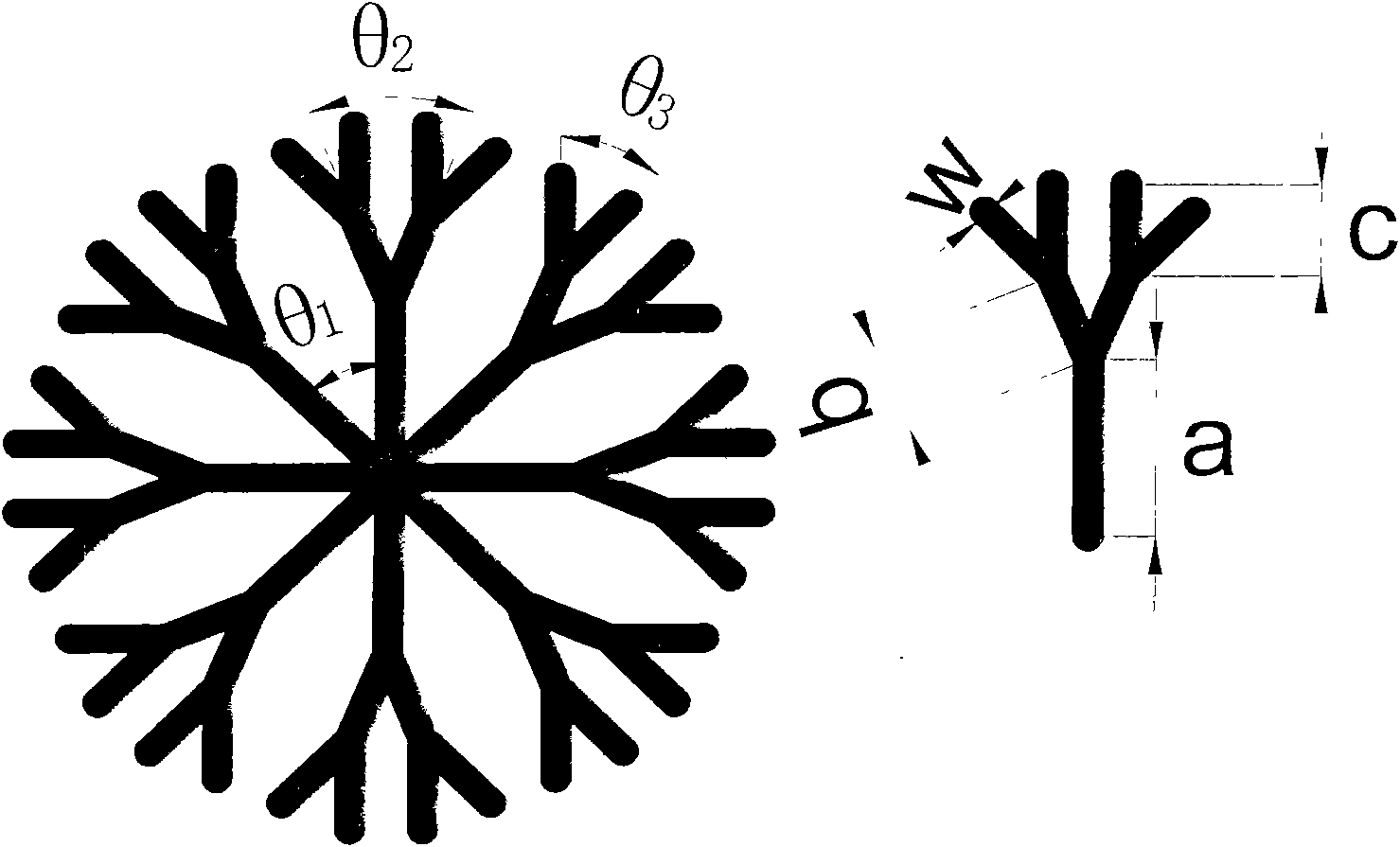

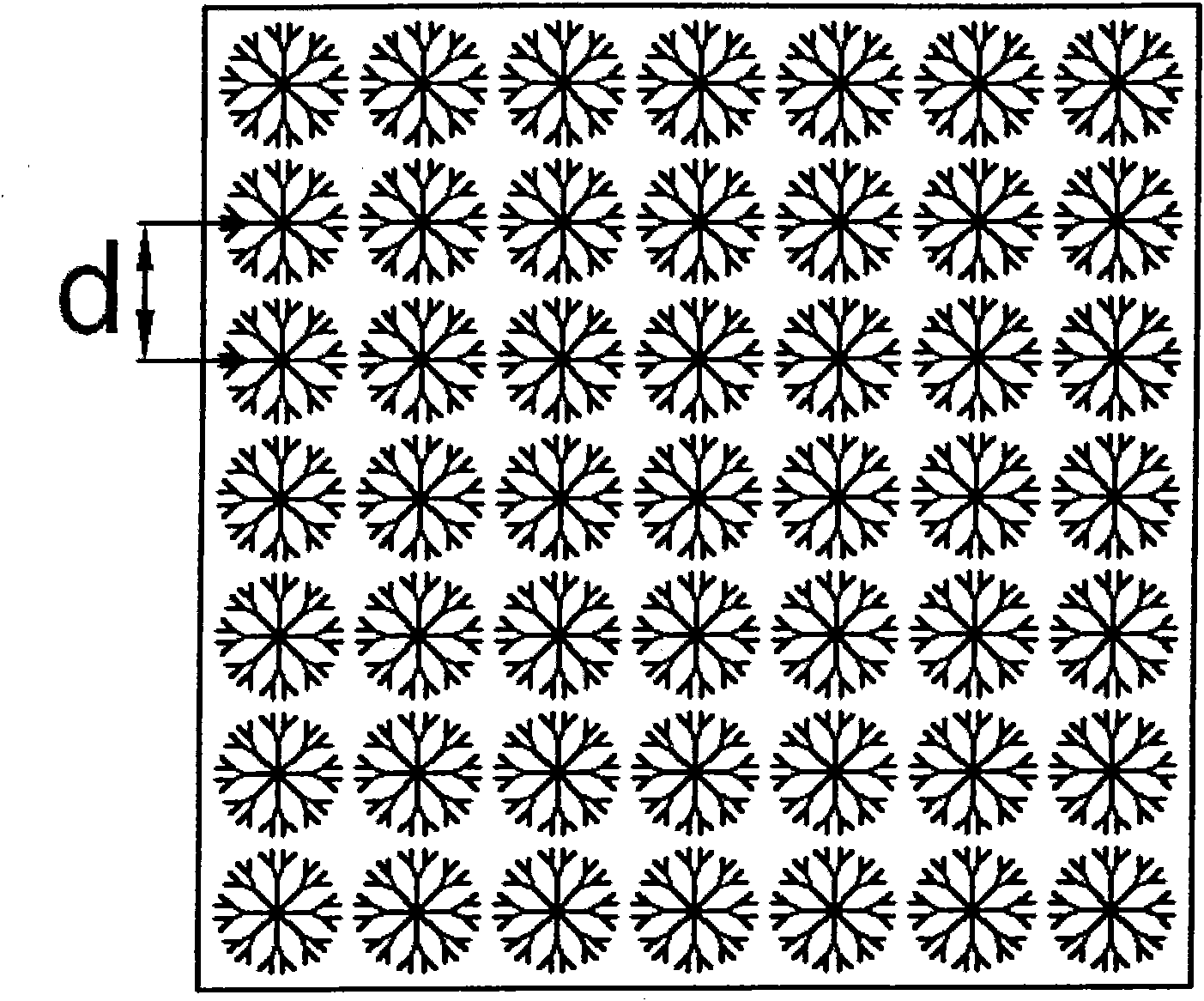

[0018] Using circuit board etching technology, a dendritic negative magnetic permeability material microstrip antenna with a central operating frequency of 2.64 GHz was fabricated. Negative magnetic permeability material microstrip antenna antenna such as figure 1 As shown, a polytetrafluoroethylene material (ε=2.65) with an area of 200mm×200mm and a thickness of 1.5mm is selected as the dielectric substrate 1 of the antenna, and the size of the metal copper radiation patch 2 on one side of the dielectric substrate 1 is 42mm×33.8 mm, the size of the square metal copper sheet 4 on the other side is 60mm×60mm, as the ground plate 4, using coaxial feed, the SMA coaxial connector 3 connects the metal radiation sheet 2 and the metal ground plate 4, and serves as the signal feed of the antenna into the source. Fig. 4 is a microstrip antenna of negative magnetic permeability material, and metal copper dendritic structure unit array 5 is etched periodically around the radiation pat...

Embodiment 2

[0020] Similar to Embodiment 1, a microstrip antenna with a dendritic structure and negative magnetic permeability material with a central operating frequency of 2.85 GHz is manufactured by circuit board etching technology. The polyethylene material (ε=2.3) with an area of 180mm×180mm and a thickness of 1mm is selected as the dielectric substrate of the antenna. The metal copper radiation patch on one side of the dielectric substrate is 38.4mm×29.8mm in size, and the square metal radiation patch on the other side is The size of the copper sheet is 50mm×50mm. It is used as the ground plane of the antenna, and the coaxial feed is adopted. The SMA coaxial connector connects the metal radiator and the metal ground plane, and serves as the signal feed source of the antenna. The copper surface is tin-plated to prevent oxidation. Copper tinned dendritic structure element arrays are etched periodically around the radiation patch and the metal ground plate. For the negative magnetic ...

Embodiment 3

[0022] Similar to Embodiments 1 and 2, a dendritic structured negative magnetic permeability material microstrip antenna with a central operating frequency of 2.45 GHz was manufactured by circuit board etching technology. Select metal copper with an area of 220mm×220mm on one side and epoxy glass cloth material (ε=4.6) with a thickness of 0.8mm as the dielectric substrate of the antenna. The size of the radiation patch on the dielectric substrate is 44.38mm×35.67mm. The size of the square metal copper sheet is 65mm×65mm. It is used as the ground plate of the antenna, and the coaxial feed is used. The SMA coaxial connector connects the metal radiator and the metal ground plate, and serves as the signal feed source of the antenna. The copper surface is silver-plated to prevent oxidation. The metallic copper silver-plated dendrite structure unit array is etched periodically around the radiation patch and the metal grounding plate. For the negative magnetic permeability microst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Metal thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com