Chemically cross-linked hyaluronic acid hydrogel nanoparticles and the method for preparing thereof

A technology of hyaluronic acid and nanoparticles, applied in cosmetic preparations, preparations for skin care, medical preparations containing active ingredients, etc., can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

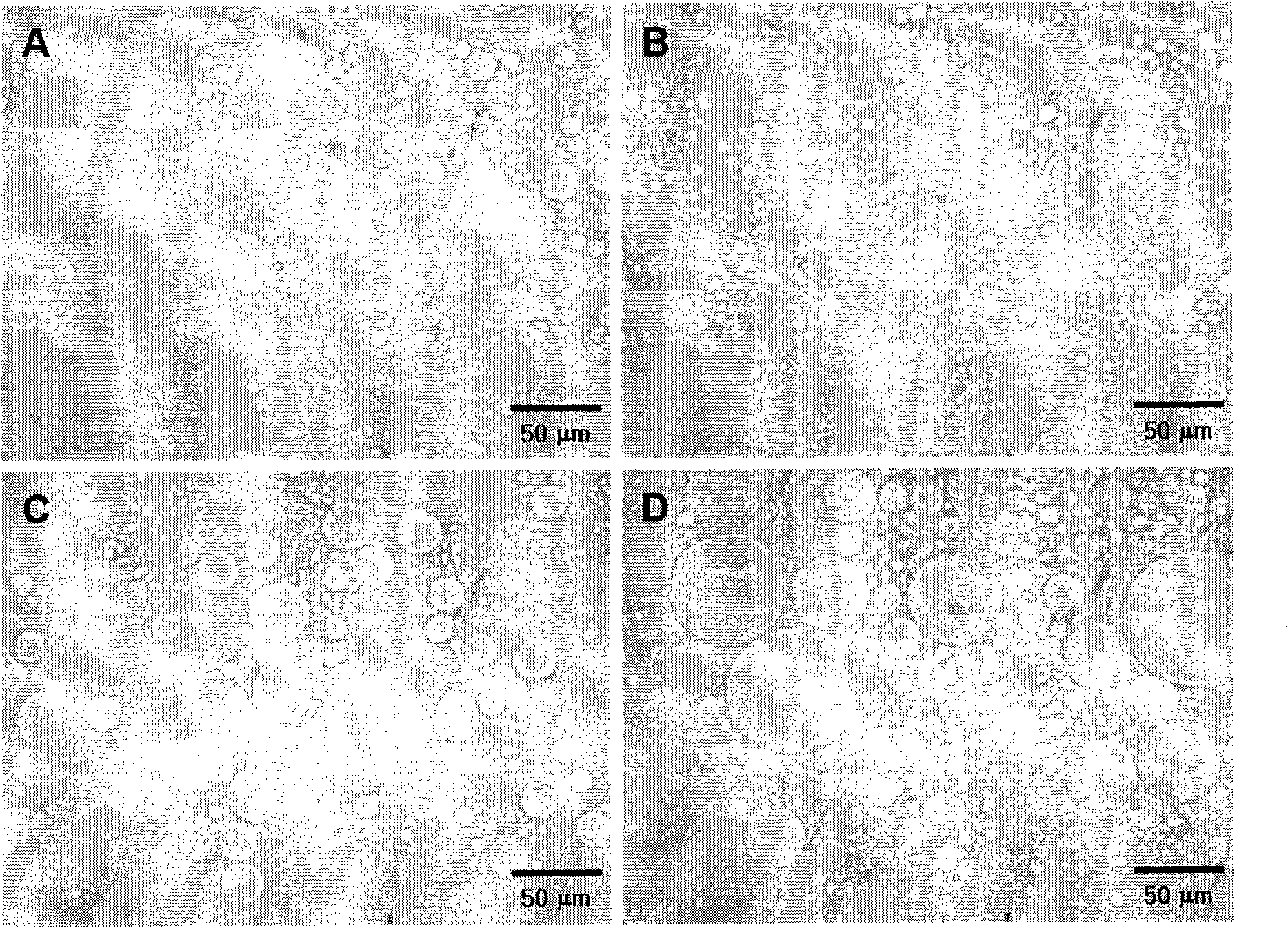

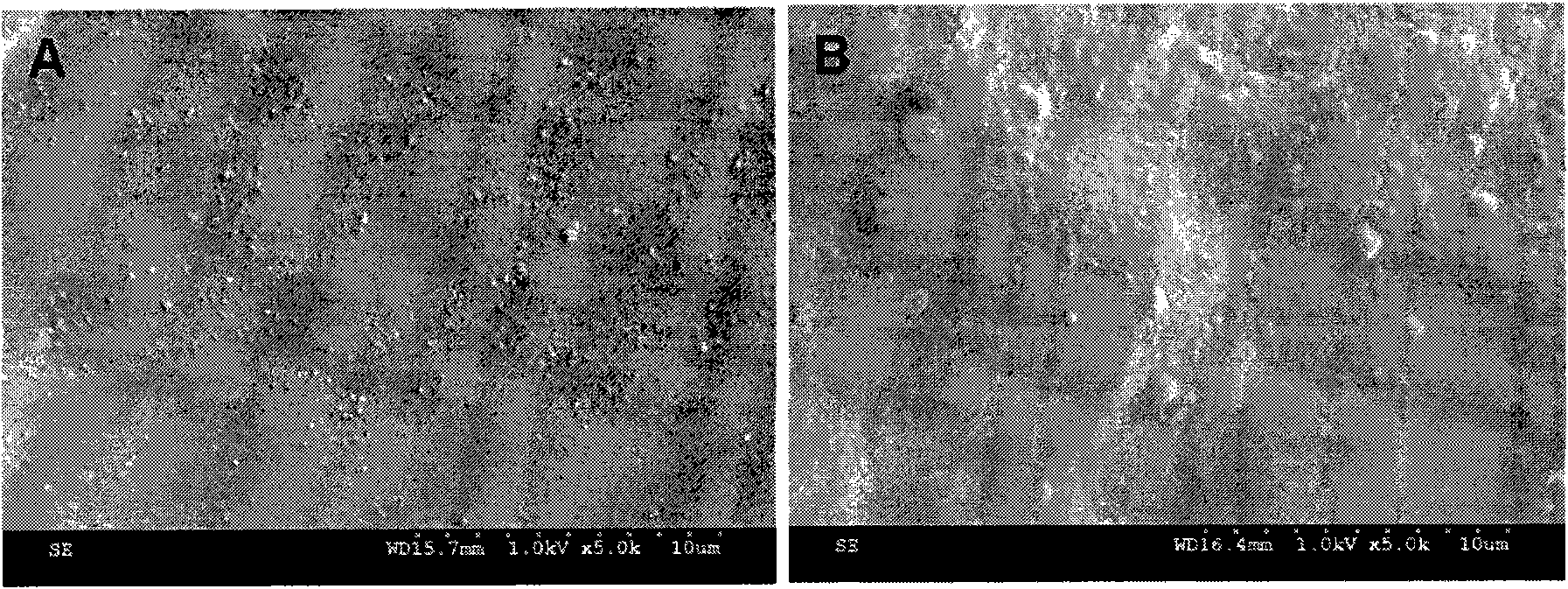

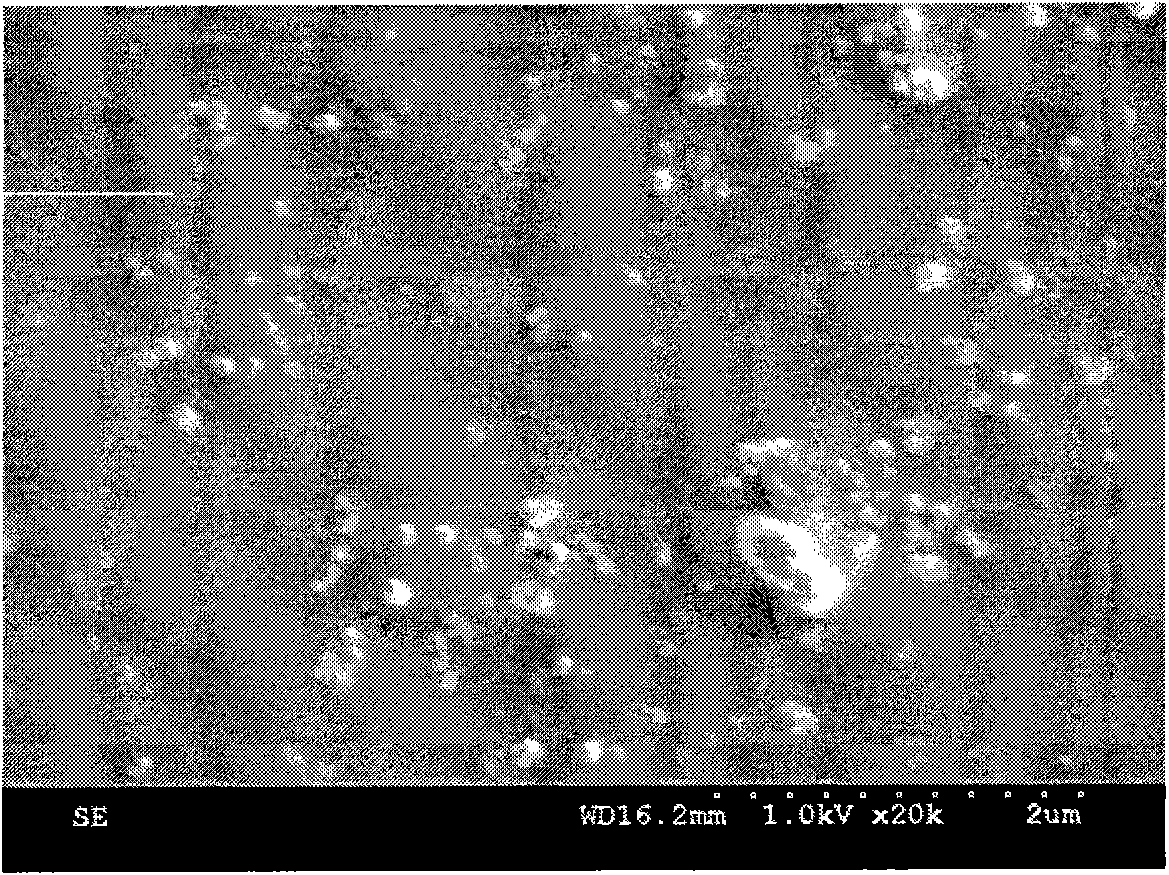

[0055] Examples 1-6: Preparation of HA hydrogel particles using dodecane as oil phase of w / o emulsion

[0056]In Examples 1-6, according to the weight composition ratio shown in the following Table 1, the surfactant A-83 or A-P135 was dissolved in dodecane using a stirrer, and the HA (number average The molecular weight is 1,500,000) and the cross-linking agent BDG or PEGDG are dissolved in 0.1N sodium hydroxide aqueous solution. When slowly adding the 0.1N sodium hydroxide solution (the sodium hydroxide solution contains HA and cross-linking agent dissolved therein) to the dodecane containing the surfactant dissolved therein, use an emulsifier at 7000 rpm The mixture was stirred and mixed at a speed per minute (rpm) for 10 minutes, thereby preparing a w / o type emulsion. The emulsion was transferred to a reactor, and the emulsion was heated at 60° C. to undergo an initial cross-linking reaction while stirring so that the w / o type emulsion was maintained. While the mixture ...

Embodiment 7-13

[0059] Embodiment 7-13: Use heptane as the oil phase of w / o emulsion to prepare hyaluronic acid hydrogel particles grain

[0060] In Examples 7-13, surfactant A-P135 was dissolved in heptane using a stirrer, and HA (number average molecular weight: 1,500,000) and The cross-linking agent PEGDG was dissolved in 0.1N aqueous sodium hydroxide solution. When slowly adding the 0.1N sodium hydroxide solution (the sodium hydroxide solution contains HA and crosslinking agent dissolved therein) to the heptane containing A-P135 dissolved therein, use an emulsifier at a speed of 7000rpm The mixture was stirred and mixed for 10 minutes to prepare a w / o type emulsion. The emulsion was transferred to a reactor, and the emulsion was heated at 60° C. to undergo an initial cross-linking reaction while stirring so that the w / o type emulsion was maintained. While the mixture was continuously stirred, the temperature of the reactor was adjusted to room temperature, and acetic acid was added ...

Embodiment 14

[0063] Example 14: Preparation of fluorescent LYD-conjugated hyaluronic acid hydrogel particles

[0064] In Example 14, surfactant A-P135 was dissolved in heptane with a stirrer according to the weight composition ratio shown in Table 3 below, and HA (number average molecular weight: 1,500,000), crosslinked The reagents PEGDG and fluorescent LYD were dissolved in 0.1 N NaOH aqueous solution. When slowly adding the 0.1N sodium hydroxide solution (the sodium hydroxide solution contains HA, PEGDC and LYD dissolved therein) to the heptane containing A-P135 dissolved therein, use an emulsifier at a speed of 7000rpm The mixture was stirred and mixed for 10 minutes to prepare a w / o type emulsion. The emulsion was transferred to a reactor, and the emulsion was heated at 60° C. to undergo an initial cross-linking reaction while stirring so that the w / o type emulsion was maintained. While the mixture was continuously stirred, the temperature of the reactor was adjusted to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com