Preparation method of Z-1,2,3,3,3-pentafluoropropylene

A technology of pentafluoropropene and hexafluoropropene is applied in the field of isomerization to obtain Z-1, which can solve the problems of low total yield and the like, and achieve the effect of high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

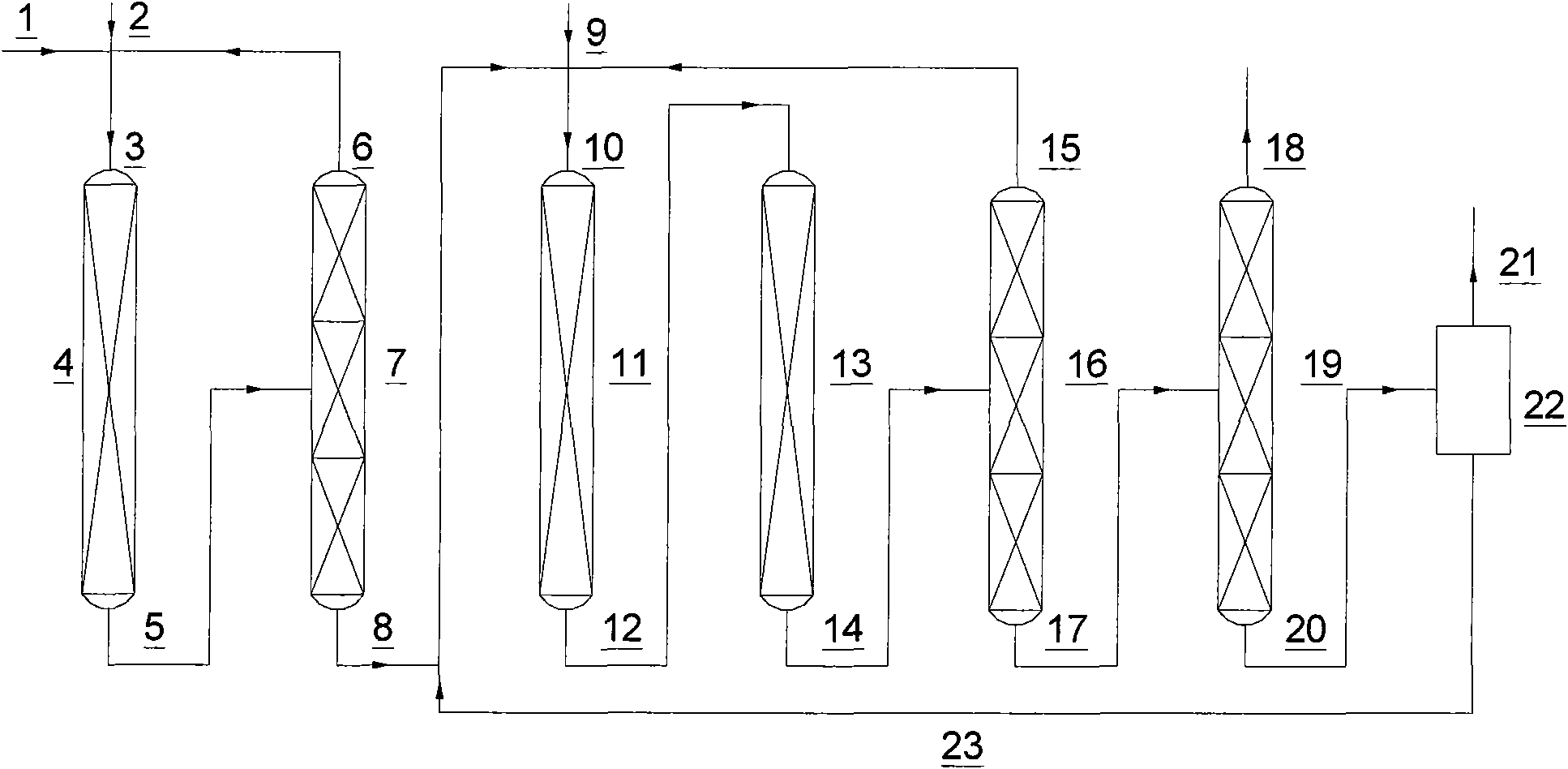

Method used

Image

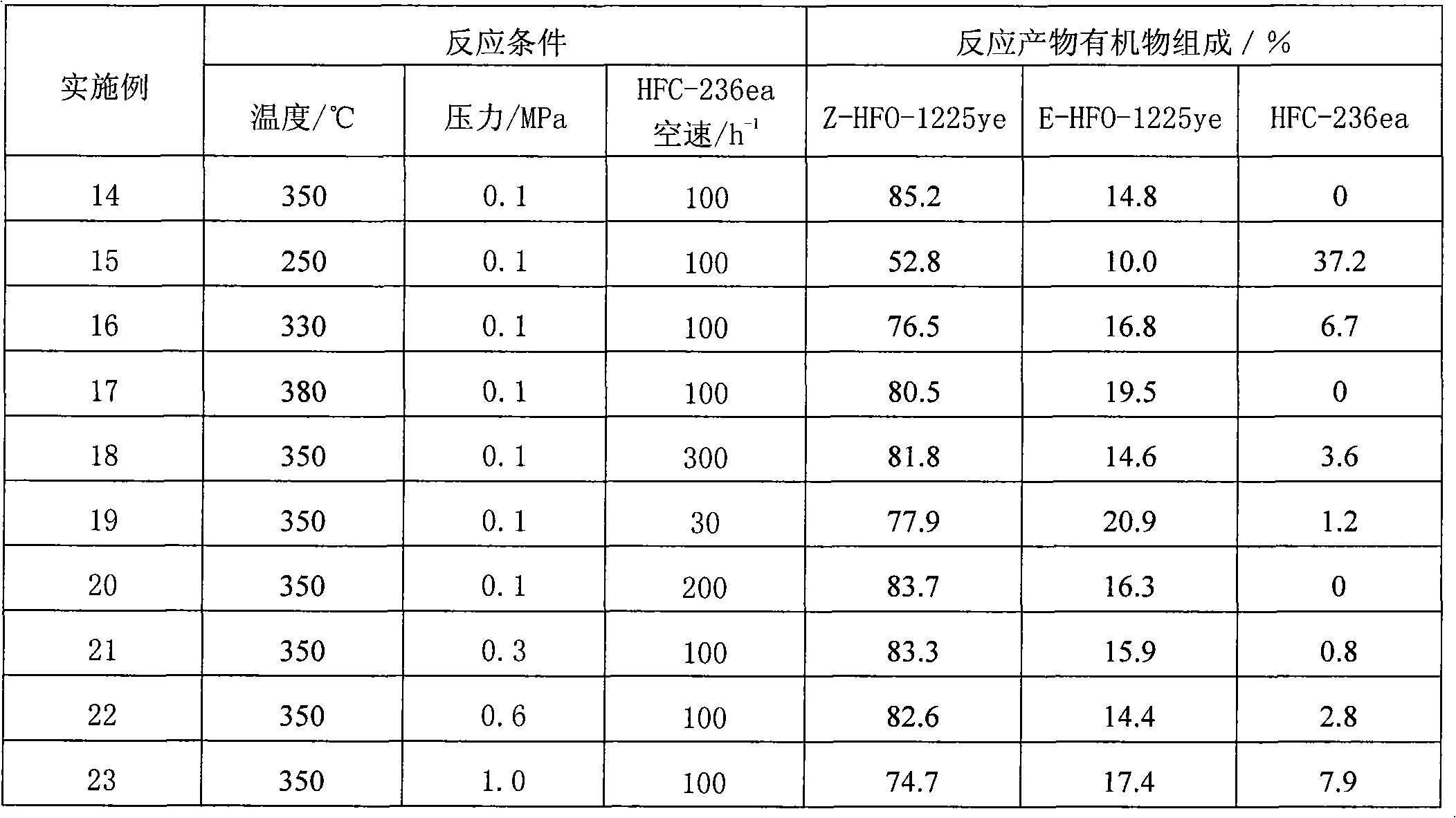

Examples

preparation example Construction

[0037] Preparation of dehydrofluorination catalyst: For the preparation method of dehydrofluorination catalyst, refer to the method disclosed in Chinese patent CN100372607C.

[0038] Preparation of isomerization catalyst: Dissolve aluminum nitrate in water, add precipitant ammonia water at 60°C, control the pH of the solution between 5.5 and 6.5, make it fully precipitate under stirring conditions, filter the formed slurry, and use Wash with deionized water until neutral, then dry at 150°C for 12 hours to obtain Al(OH) 3 .

[0039] The obtained Al(OH) 3 Uniformly mixed with tin dioxide according to the required mass ratio, and pressed into tablets to obtain a catalyst precursor. The catalyst precursor was roasted in a muffle furnace at 400°C for 10 hours, then loaded into a tubular reactor, and heated to 300°C. Flow hydrogen fluoride gas for 2 hours, then raise the temperature to 350°C at a rate of 1°C / min, and continue fluorination for 10 hours to prepare an isomerization c...

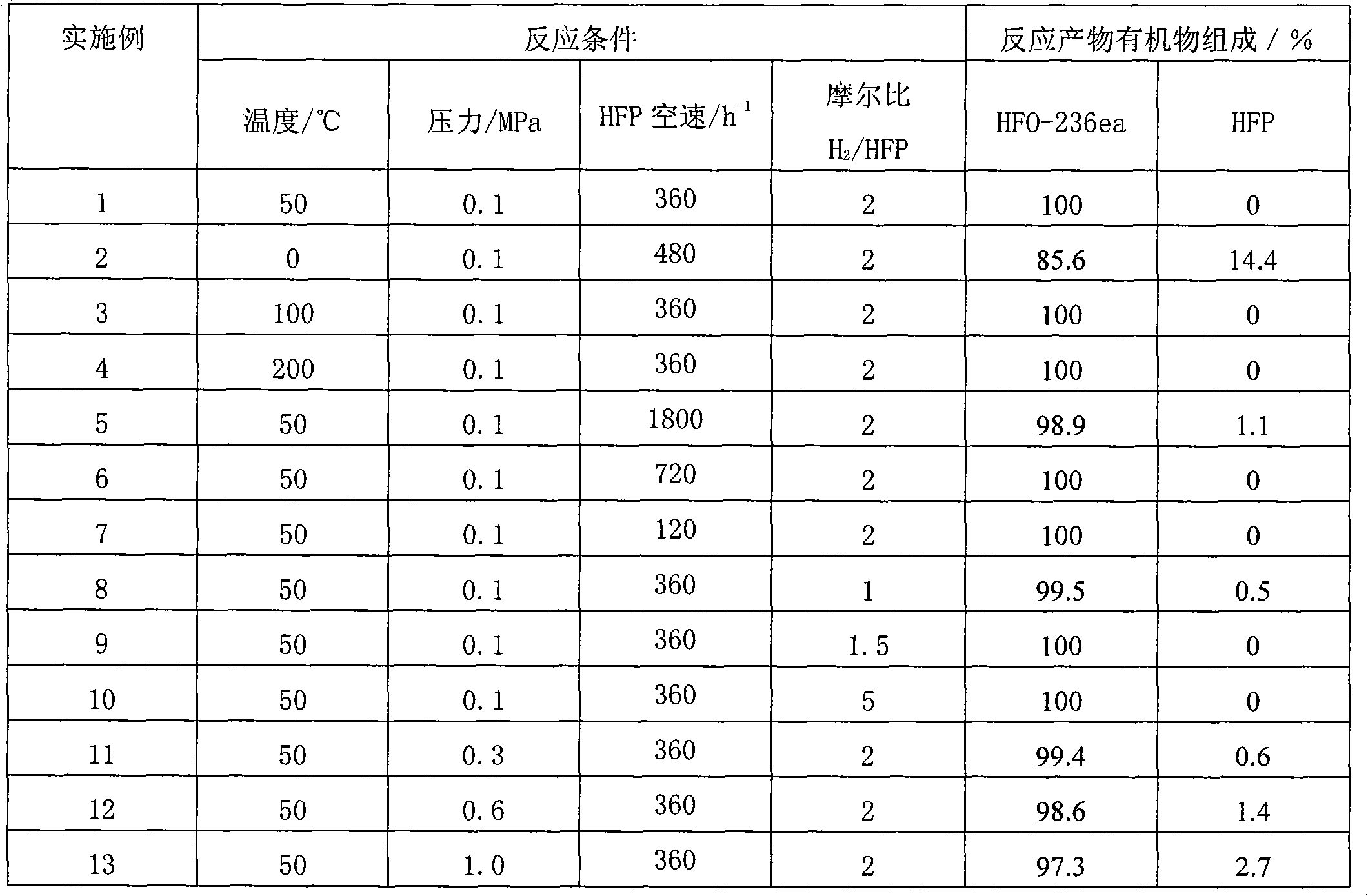

Embodiment 1

[0041] 50 ml of a commercially available 2% Pd / C catalyst was added to a carbon steel pipe with an inner diameter of 38 mm. The temperature of the first reactor is 50°C, and H 2 and HFP, control H 2 The molar ratio to HFP is 2, and the space velocity of HFP is 360h -1 , reaction pressure 0.1MPa, after reacting for 20h, use gas chromatography to analyze the composition of organic matter in the reaction product, the results are shown in Table 1.

Embodiment 2

[0043] Add 50 ml of a commercially available 5% Pd / C catalyst into a glass tube with an inner diameter of 38 mm. The first reactor was placed in an ice bath at 0°C, and H 2 and HFP, control H 2 The molar ratio to HFP is 2, and the space velocity of HFP is 480h -1 , reaction pressure 0.1MPa, after reacting for 20h, use gas chromatography to analyze the composition of organic matter in the reaction product, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com