Schottky concretionary battery with protection ring structure and manufacture method thereof

A technology of nodule battery and protection ring, which is applied in the fields of semiconductor, nuclear physics and micro-energy, can solve the problems of low sensitivity and energy conversion efficiency, and achieve the effect of improving energy conversion efficiency, increasing open circuit voltage and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

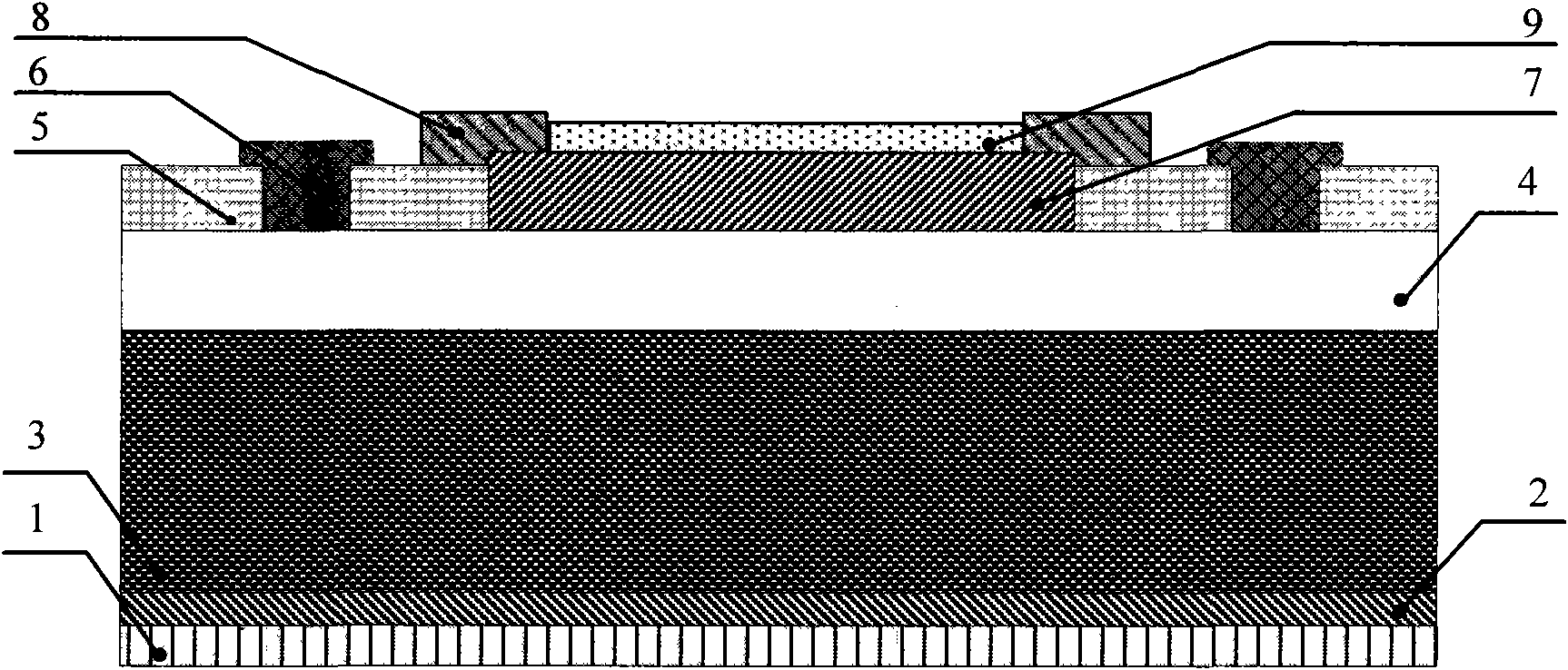

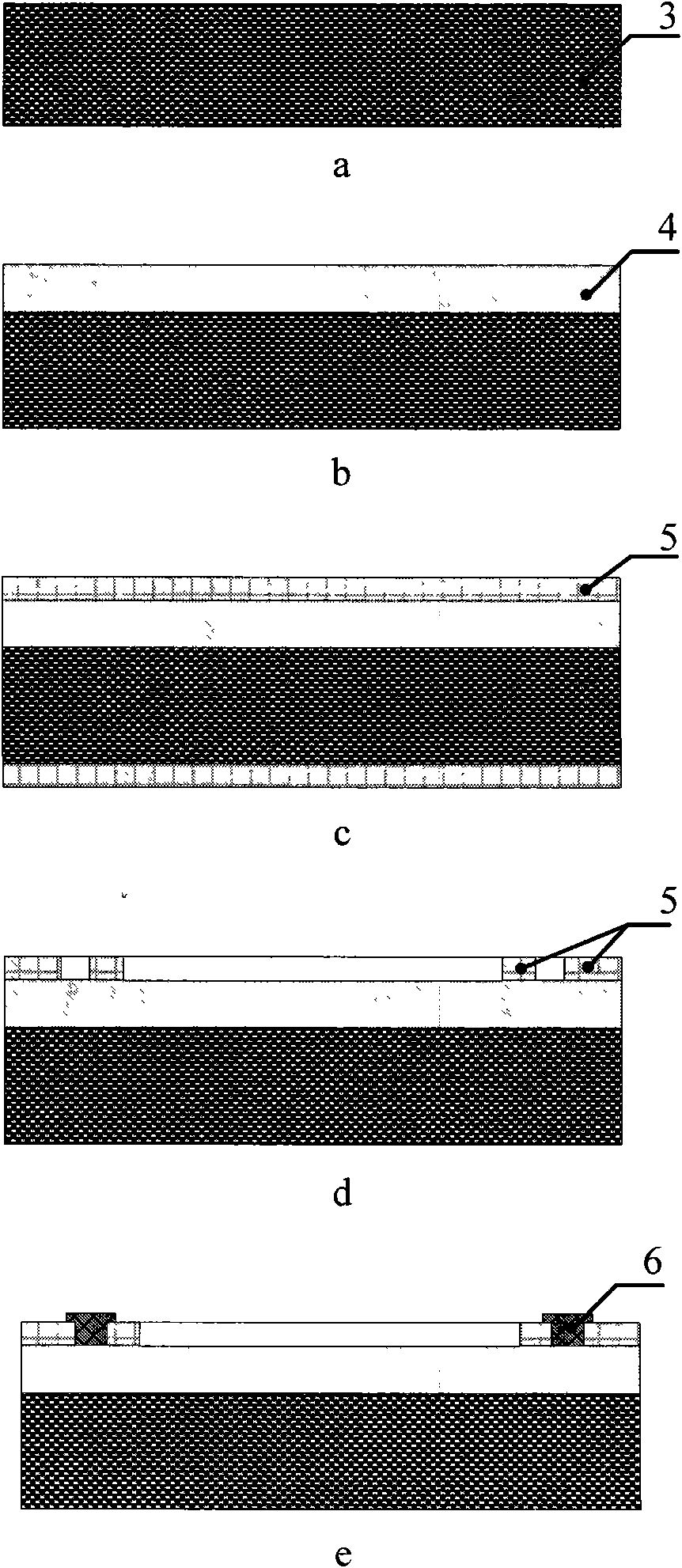

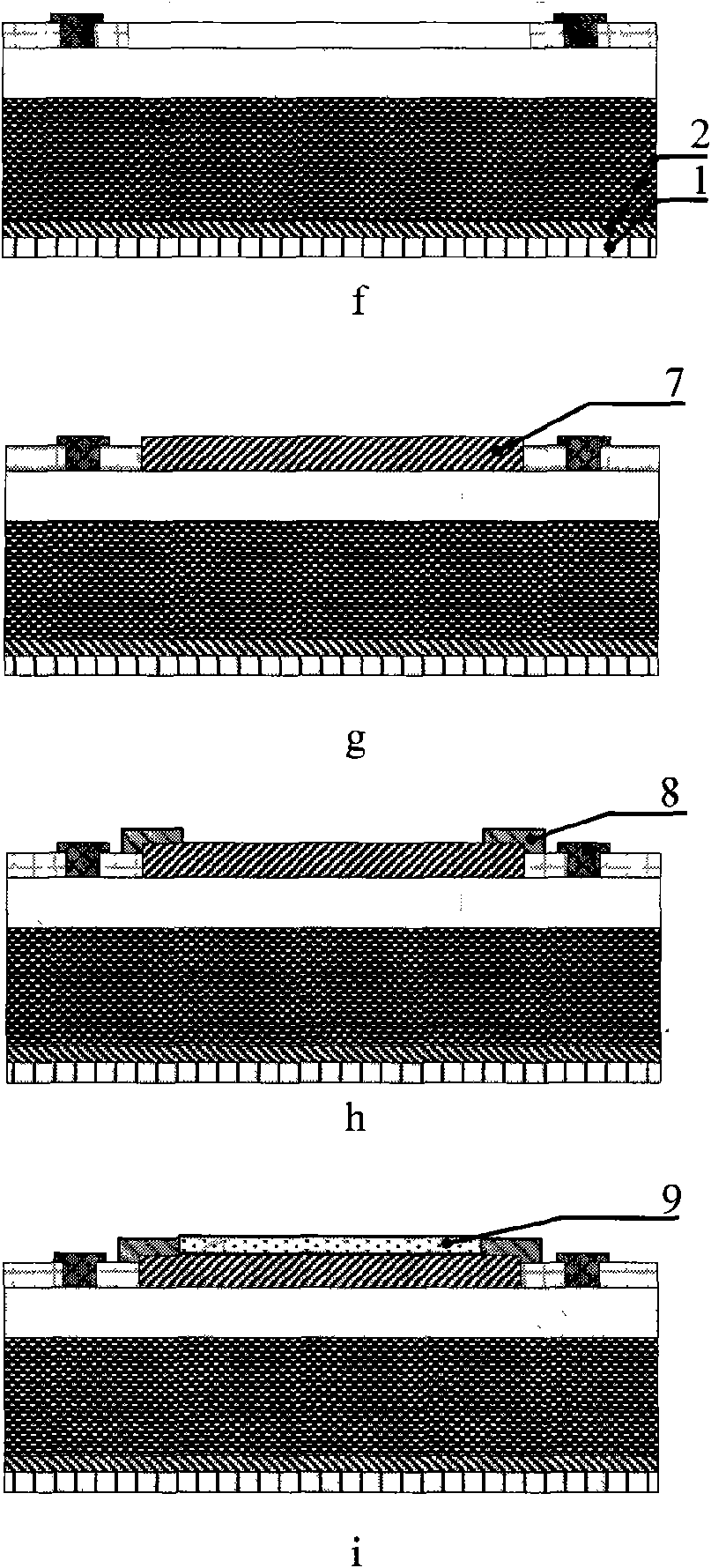

[0032] refer to figure 1 , image 3 , the Schottky nodule cell with guard ring structure in this embodiment includes isotope 9, upper electrode metal layer 8, barrier metal layer 7, guard ring 6, passivation layer 5, intrinsic i layer 4, n + Type SiC layer 3, ohmic contact layer 2, bottom electrode metal layer 1; where n + The doping concentration of type SiC layer 3 is 5×10 17 cm -3 , a thickness of 300 μm, a circular shape; a thickness of 10 μm, a doping concentration of 5×10 14 cm -3 , the intrinsic i layer 4 with the same shape as the n+ type SiC layer 3 is located at n + type SiC layer 3; the shape of the barrier metal layer 7 can be any shape such as circular or square; the guard ring 6 is located in the outer annular area of the barrier metal layer 7 above the intrinsic i layer 4, and the inner ring of the guard ring 6 and The outer ring spacing of the barrier metal layer 7 is 100 μm; the shape of the upper electrode metal layer 8 is circular, spanning the inte...

specific Embodiment 2

[0044] refer to figure 1 , Figure 4 , the present embodiment is a Schottky nodule cell with a guard ring structure, including isotope 9, upper electrode metal layer 8, barrier metal layer 7, guard ring 6, passivation layer 5, intrinsic i layer 4, n + Type Si layer 3, ohmic contact layer 2, bottom electrode metal layer 1; n + The doping concentration of type Si layer 3 is 5×10 16 cm -3 , a square shape; the thickness is 20 μm, and the doping concentration is 5×10 14 cm -3 Intrinsic i layer 4 located at n + The front side of type Si layer 1; The shape of barrier metal layer 7 can be any shape such as circle or square; Guard ring 6 is positioned at the peripheral annular area of barrier metal layer 7 above intrinsic i layer 4, guard ring 6 inner ring and The distance between the outer rings of the barrier metal layer 7 is 200 μm; the upper electrode metal layer 8 is two protrusions drawn from the interface between the passivation layer 5 and the barrier metal layer 7; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com