(GeTe)*(SbTe*)*base dilute magnetic semiconductor material for storing information

A dilute magnetic semiconductor and information storage technology, applied in the field of microelectronics, can solve problems such as doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

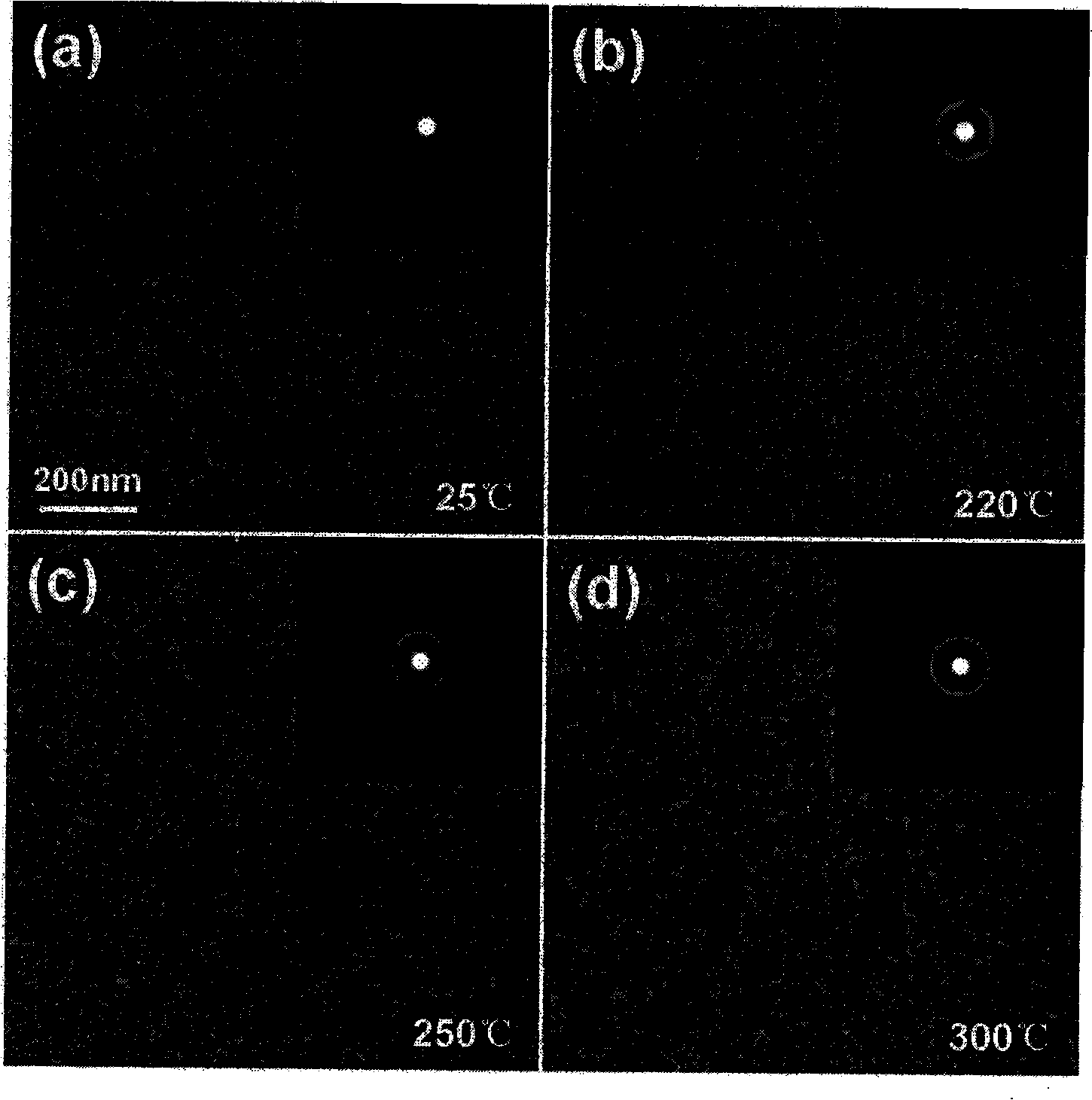

[0016] Using double target co-sputtering method with Mn and Ge 2 Sb 2 Te 5 Mn-Ge prepared on Si wafer by two relatively independent targets 2 Sb 2 Te 5 Phase-change thin film material, meanwhile, in order to observe the microstructure of the phase-change memory material in the present invention, the method of dual-target co-sputtering is also used to use Mn and Ge 2 Sb 2 Te 5 Two relatively independent targets prepared Mn-Ge on the TEM grid 2 Sb 2 Te 5 Phase change film materials. Argon gas pressure during sputtering is 0.5Pa, Mn and Ge 2 Sb 2 Te 5 The power on the target is 60 watts of direct current and 100 watts of radio frequency respectively, and the thickness of the prepared phase change thin film material can be controlled by controlling the sputtering time. X-ray fluorescence spectrum analysis showed that the composition of the material was Mn 0.35 (Ge 2 Sb 2 Te 5 ) 0.65 .

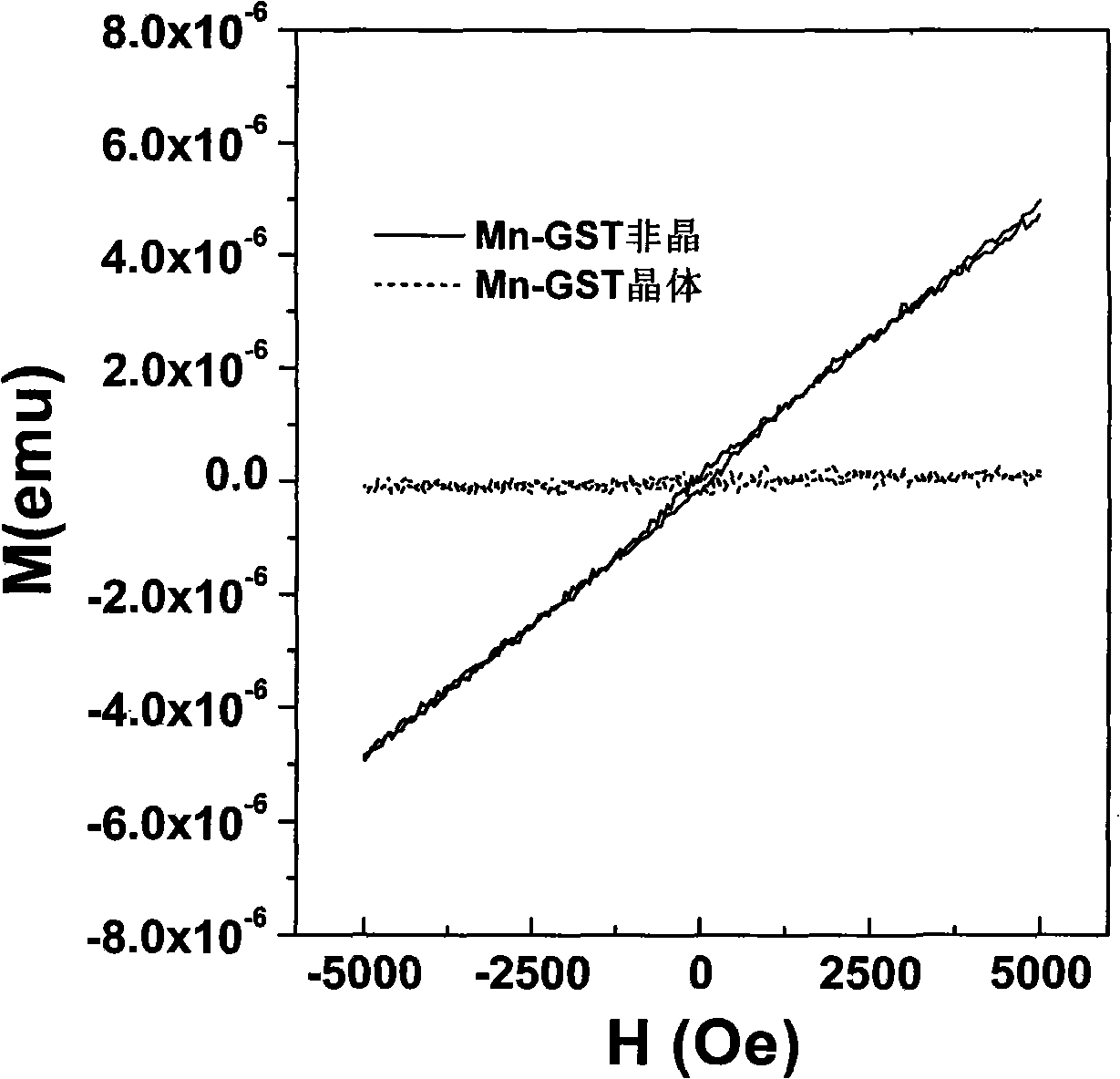

[0017] Will get Mn 0.35 (Ge 2 Sb 2 Te 5 ) 0.65 The phase-change thin fi...

Embodiment 2

[0021] co-sputtering with Co and Ge 2 Sb 2 Te 5 Co-Ge prepared on silicon substrate by two relatively independent targets 2 Sb 2 Te 5 Phase change film materials. Argon gas pressure during sputtering is 0.5Pa, Co and Ge 2 Sb 2 Te 5 The power on the target is 200 watts of radio frequency and 100 watts of radio frequency respectively, and the thickness of the prepared phase change thin film material can be controlled by controlling the sputtering time. X-ray fluorescence spectroscopic analysis showed that the composition of the material was Co 0.04 (Ge 2 Sb 2 Te 5 ) 0.96 .

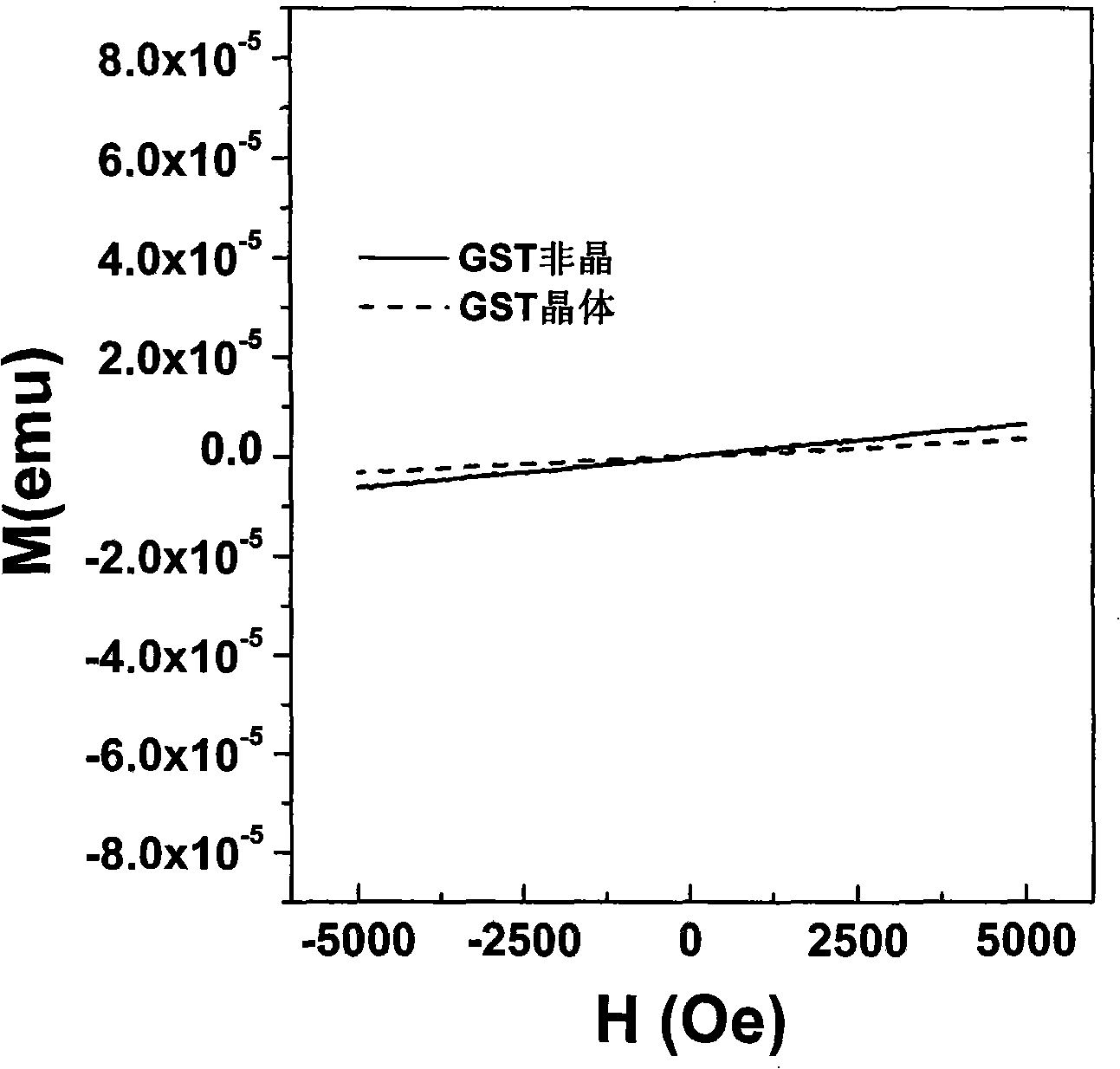

[0022] Will get Co 0.04 (Ge 2 Sb 2 Te 5 ) 0.96 The phase-change thin film material is annealed at a temperature of 300 degrees under the protection of a high-purity argon atmosphere. Figure 4 Shown are the hysteresis loops of the samples measured with an AC gradient magnetometer before and after annealing treatment and the enlarged local hysteresis loops (the silicon substrate has been de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com