Manufacturing method for protein structure quick switch memristor array

A protein structure and fast switching technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of high production cost memristor switching speed, and achieve low production cost, cheap price and simple manufacturing method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

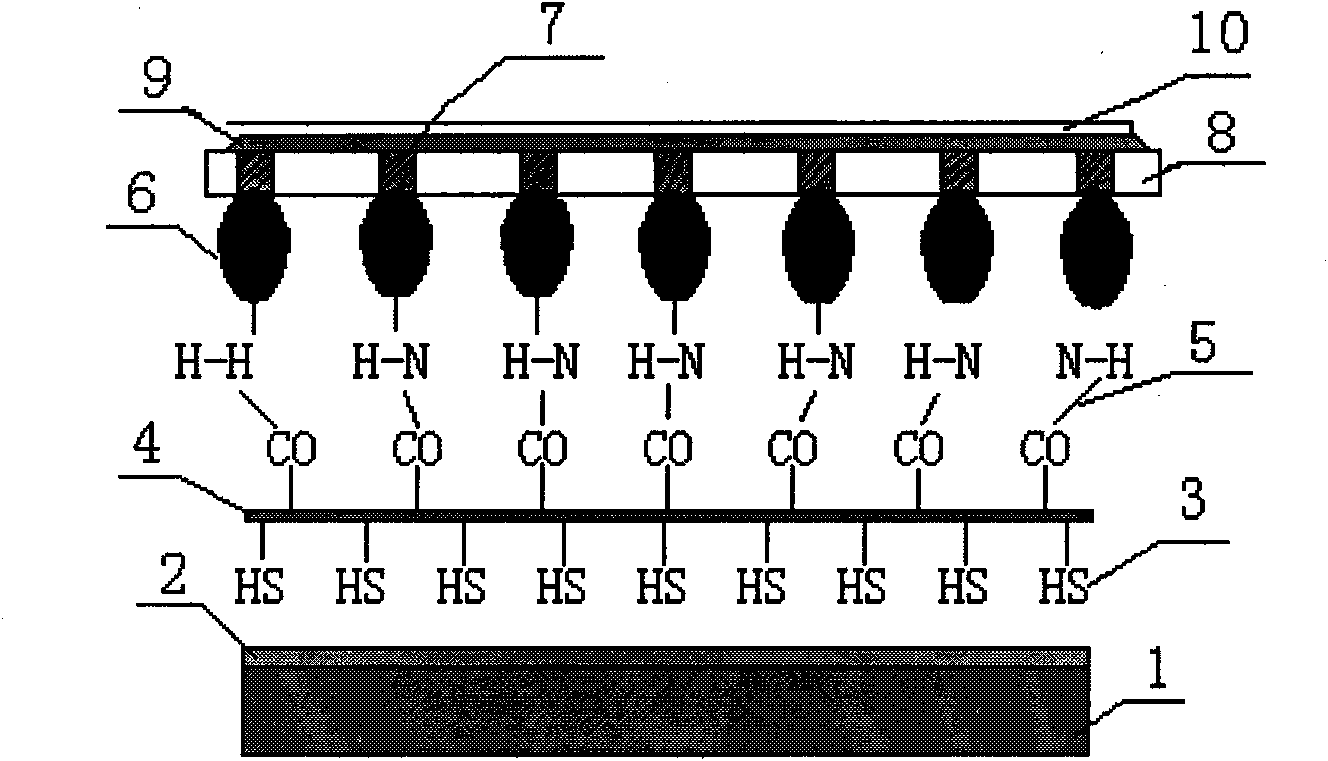

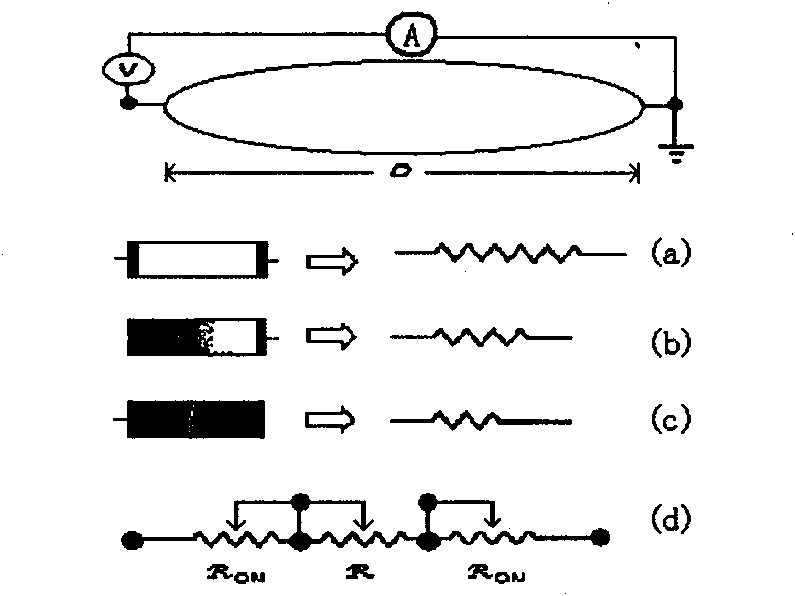

[0008] Specific Embodiment 1: In this embodiment, the method for manufacturing a protein-structured fast switching memristor array is manufactured according to the following steps: 1. A layer of gold with a thickness of 70-90 nm is fabricated on the upper surface of a silicon wafer by magnetron sputtering. 2. Immerse the silicon wafer coated with gold film into a solute concentration of 5×10 -3 The ethanol solution of mol / L 11-mercapto-1-undecanol was reacted for 5-7 hours to form a mercapto-hydrophilic surface on the surface of the gold film. The mass concentration is 70% to 90%; 3. The silicon chip with the mercapto group hydrophilic surface prepared in step 2 is immersed in an alkali ether solution of epichlorohydrin with a solute concentration of 0.6 to 0.8 mol / L and reacted for 3 to 5 hours, That is, an epoxy surface is formed on the hydrophilic surface, wherein the solvent of the alkali ether solution of epichlorohydrin consists of NaOH solution with a concentration of 0...

specific Embodiment approach 2

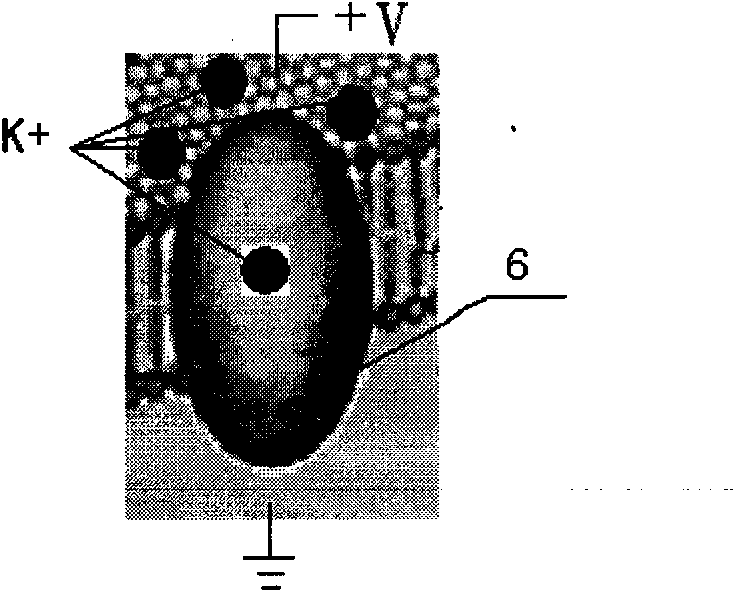

[0013] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 7, 60-100 mmol of K is added dropwise on the surface of the nanopore array film. + ionic liquid. Other steps and parameters are the same as those in Embodiment 1.

[0014] In this embodiment, different numbers of K + Ion-implanted protein-structured memristor cell switch arrays.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step seven, 60 to 100 mmol of Na is added dropwise on the surface of the nanopore array film. + ionic liquid. Other steps and parameters are the same as those in Embodiment 1.

[0016] In this embodiment, a protein-structured memristor unit switch array with different numbers of Na+ ions implanted under the action of an external bias is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com