High-frequency quick-recovery diode

A technology for recovering diodes and diodes, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of high chip price, difficult procurement, short reverse recovery time, etc., to achieve convenient procurement, reduce production costs, and improve withstand voltage. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

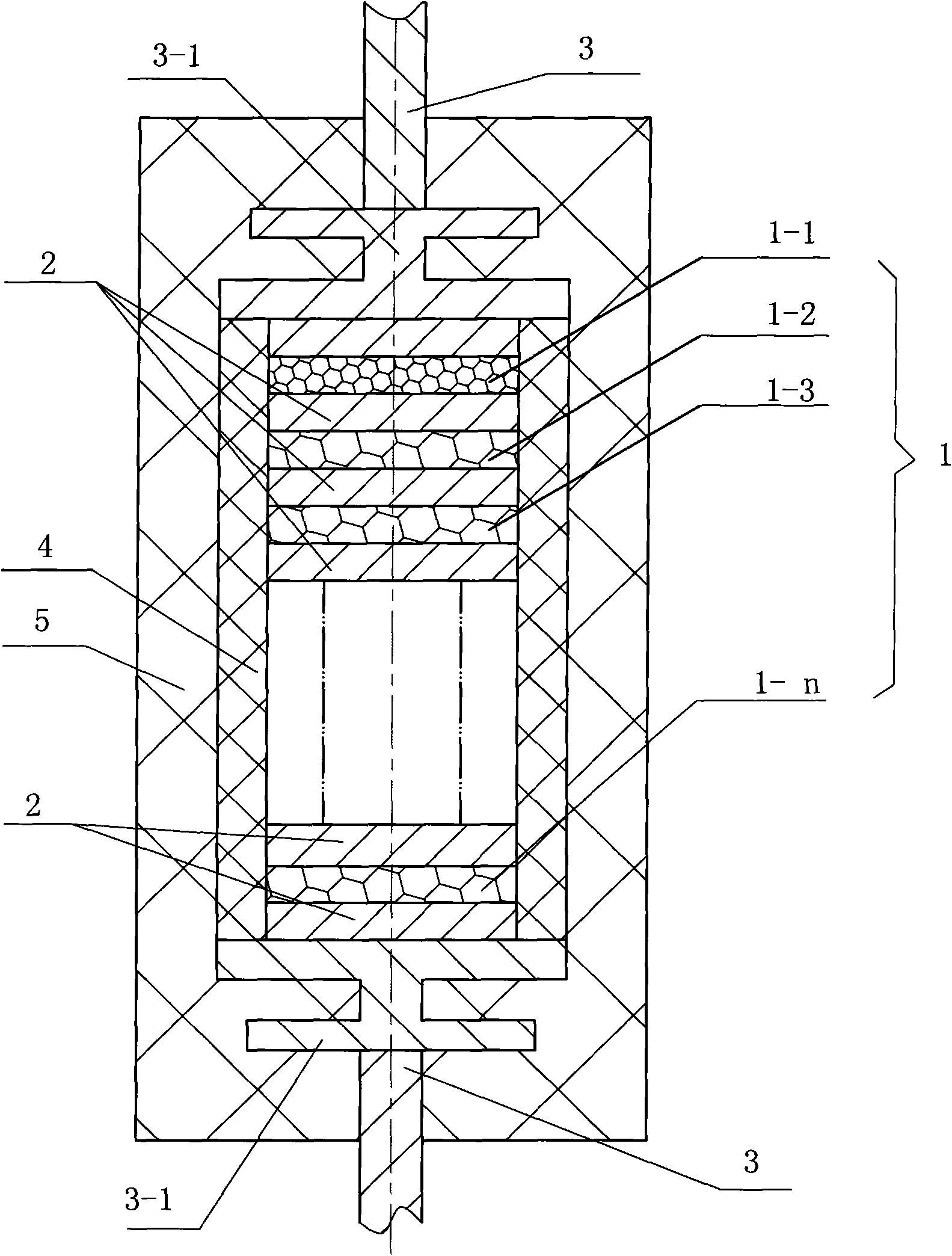

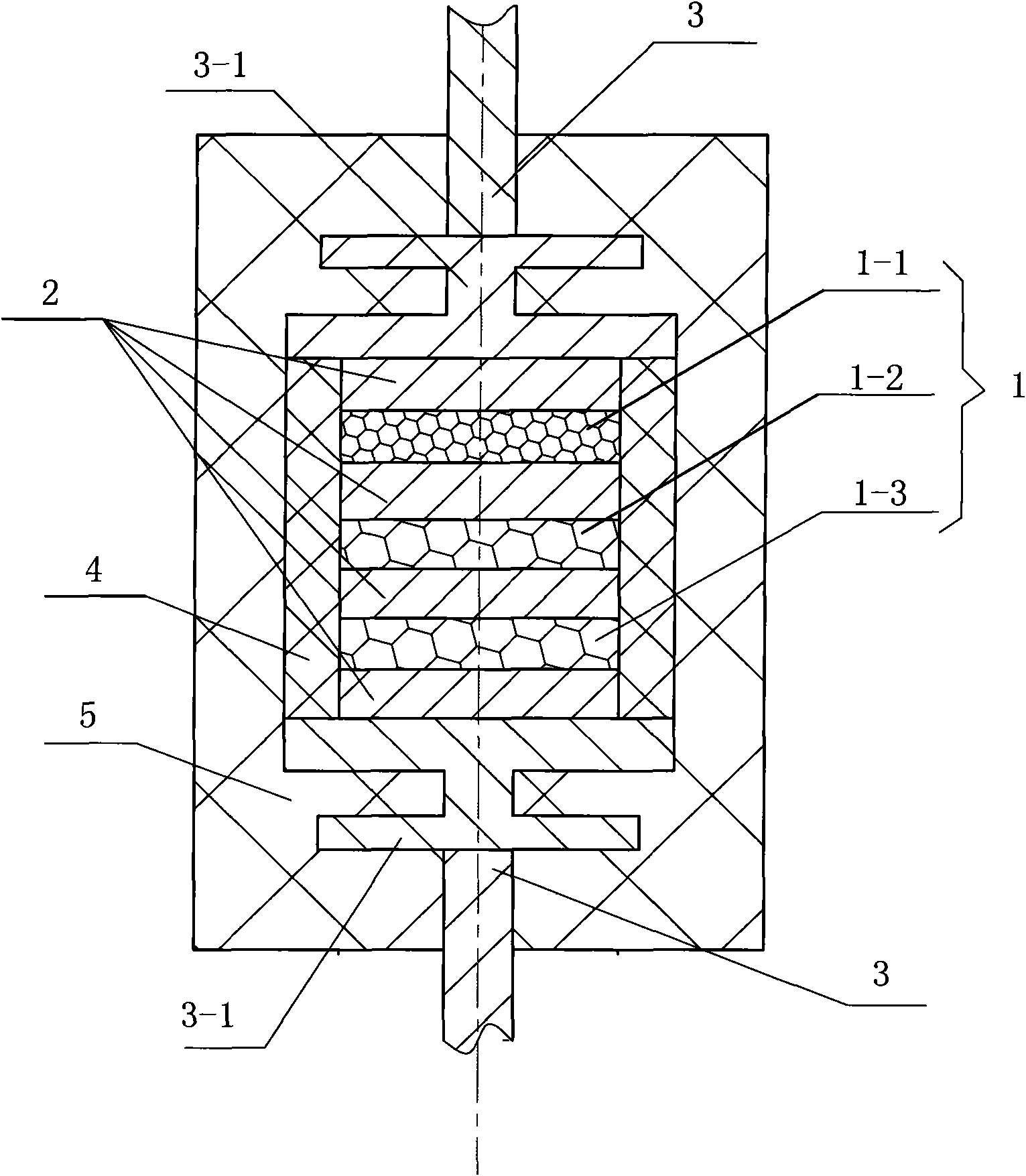

[0012] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, such as figure 1 As shown, a high-frequency fast recovery diode includes a diode chip set 1, a soldering piece 2, a lead wire 3, a lead head 3-1, a rubber coating layer 4 and a plastic package 5; the diode chip set 1 includes n pieces of diode chips 1- 1, 1-2, 1-3, ... 1-n, arranged in the order of the same polarity, each piece of diode chip 1-1, 1-2, 1-3, ... Both sides of .1-n are provided with a soldering piece 2 and connected to the welding piece 2, and the end faces of the lead heads 3-1 of the two diode leads 3 are respectively connected to the welding pieces 2 at both ends of the diode chip set 1, and the diode chip set 1 and the outer periphery of the soldering piece 2 are provided with a rubber coating layer 4, and the two lead heads 3-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com