Temperature-sensitive hydrogel containing adamantyl and preparation method and application thereof

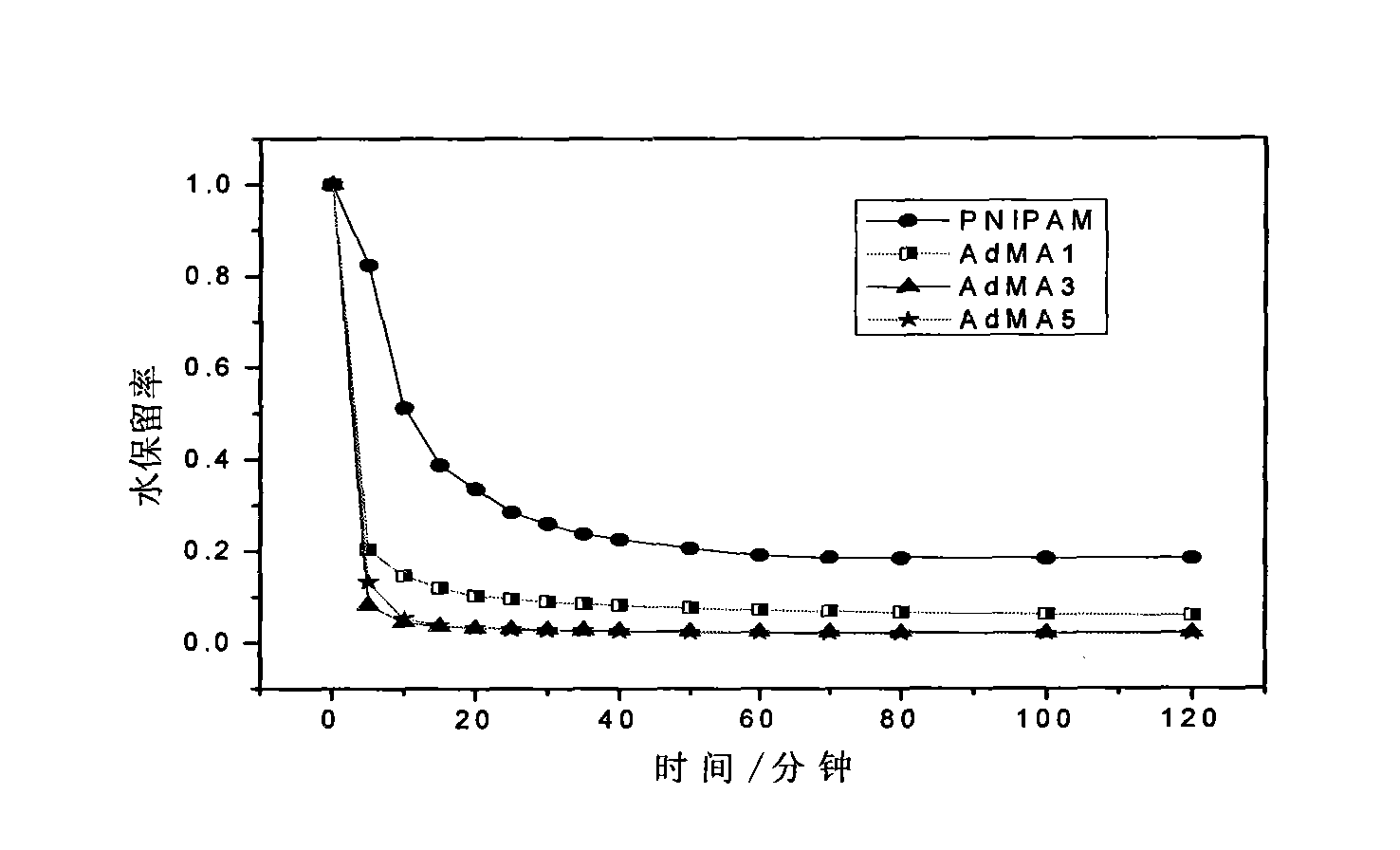

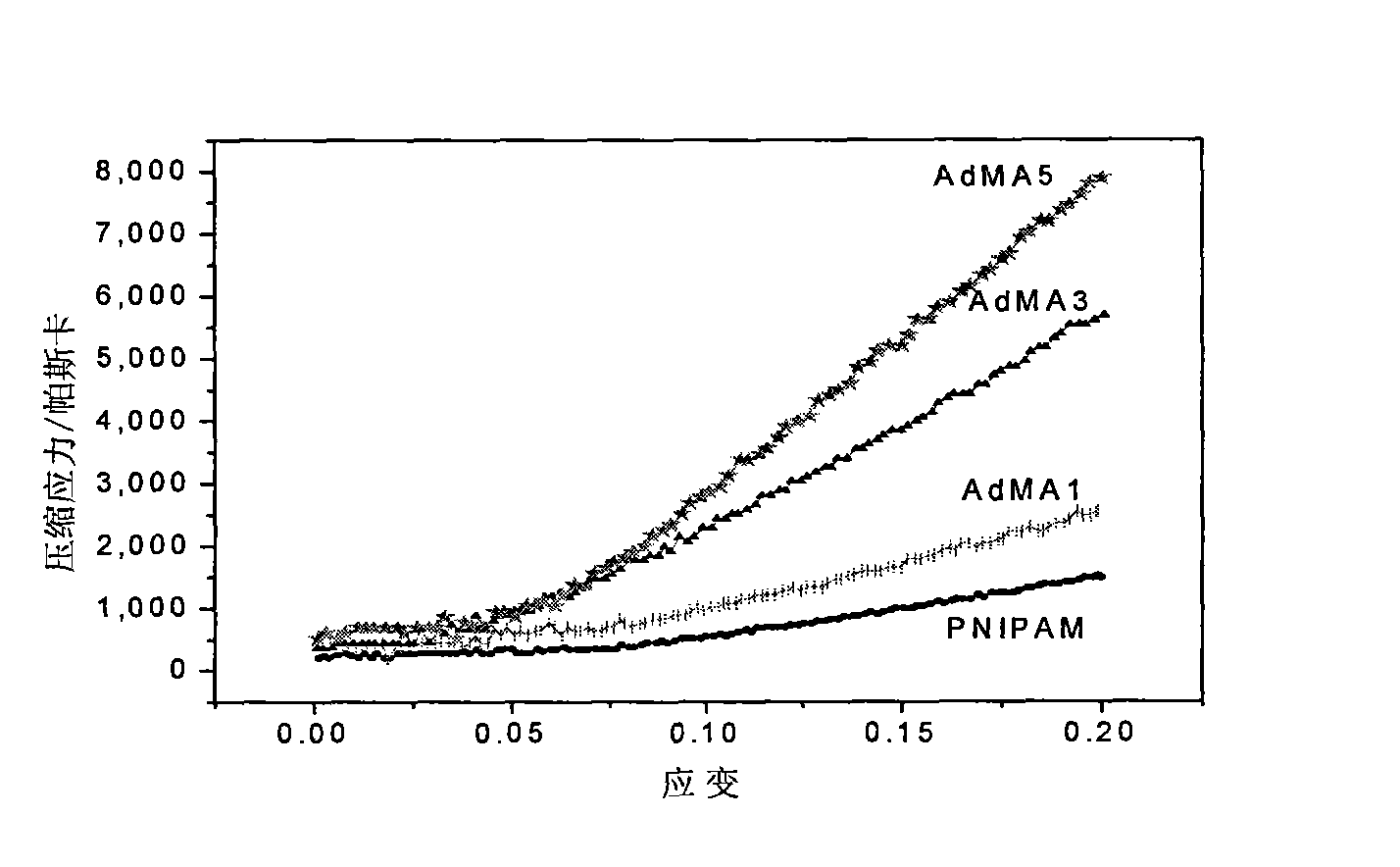

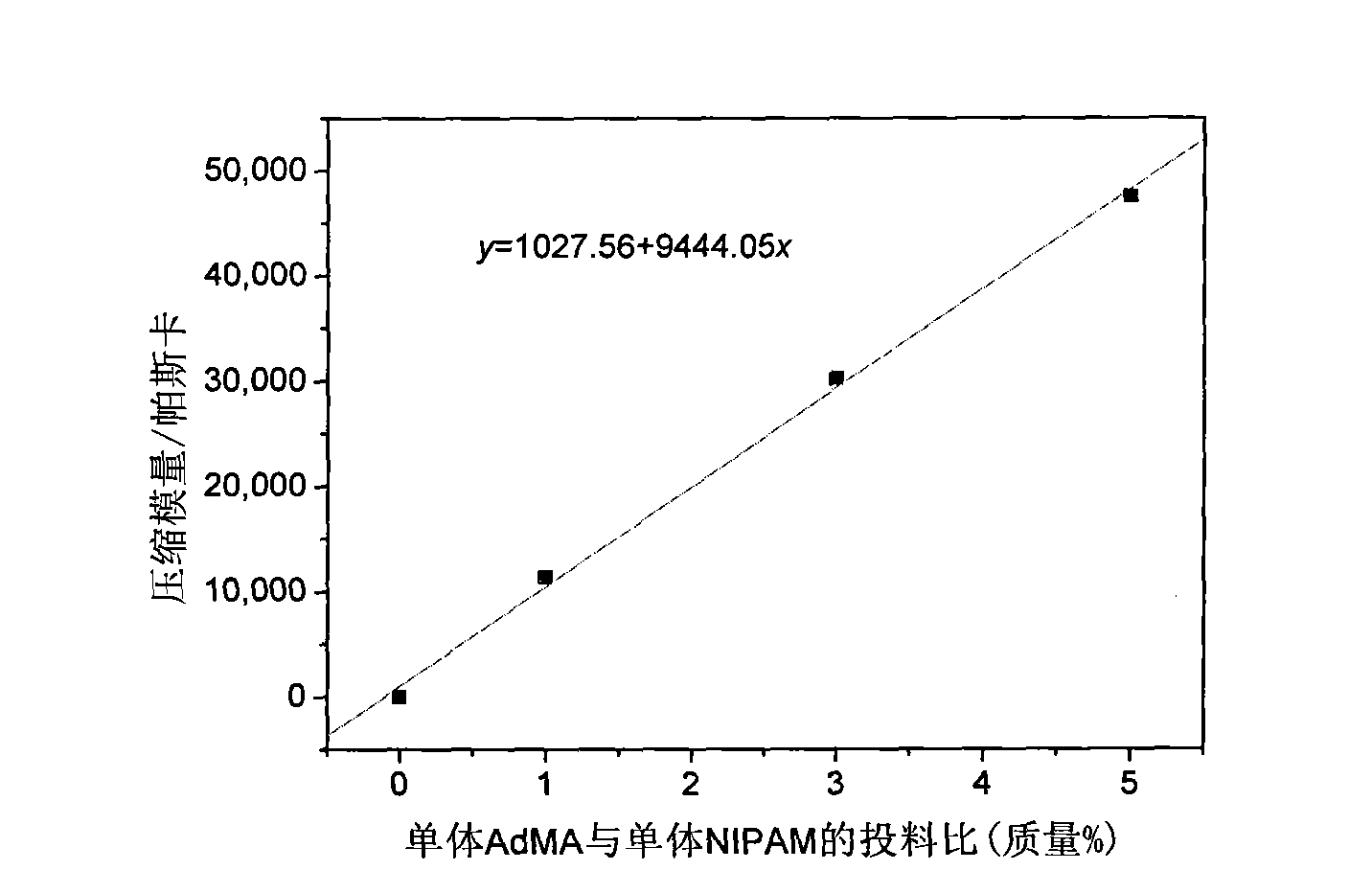

A temperature-sensitive hydrogel and adamantyl technology, applied in the field of temperature-sensitive hydrogel and its preparation, can solve the problems of not being able to respond quickly at the same time, and achieve rapid deswellability, high mechanical strength, and response rate fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh the hydrophobic monomer adamantyl methacrylate (AdMA, the structure is as R in the general formula 0 =CH 3 , R 1 = H, R 2 = H, R 3=H) 0.01g in a small reaction vial, then add 1g of N-isopropylacrylamide (NIPAM) and 30mg of N,N'-methylenebisacrylamide, then add 7ml of 1,4-dioxane , shake until the solids are completely dissolved, add 12.5 mg of initiator azobisisobutyronitrile, and seal the tube after 4 cycles of vacuum pumping and nitrogen filling, and put the reaction bottle in an oil bath at 75°C for 10 h. The obtained colorless and transparent gel was soaked in distilled water for 5 days, first soaked in distilled water at 20°C for 24 hours, then placed in distilled water at 40°C to allow it to shrink naturally, and then changed the water, after four cycles, keep soaking in distilled water at room temperature , to obtain adamantyl-containing temperature-sensitive hydrogel AdMA1.

Embodiment 2

[0042] The preparation of the adamantyl-containing temperature-sensitive copolymer hydrogel AdMA3, only the feed ratio of the hydrophobic monomer AdMA and NIPAM is 3%, and the other raw material feed ratios and reaction steps are the same as in Example 1, and the adamantyl-containing temperature-sensitive copolymer hydrogel is obtained. Sensitive hydrogel AdMA3.

Embodiment 3

[0044] The preparation of the temperature-sensitive copolymer hydrogel AdMA5 containing adamantyl, only the feed ratio of hydrophobic monomer AdMA and NIPAM is 5%, and the feed ratio and reaction steps of other raw materials are the same as in Example 1, and the temperature-sensitive copolymer hydrogel containing adamantyl is obtained. Sensitive hydrogel AdMA5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com