Al-Mo-W-Ti quaternary alloy

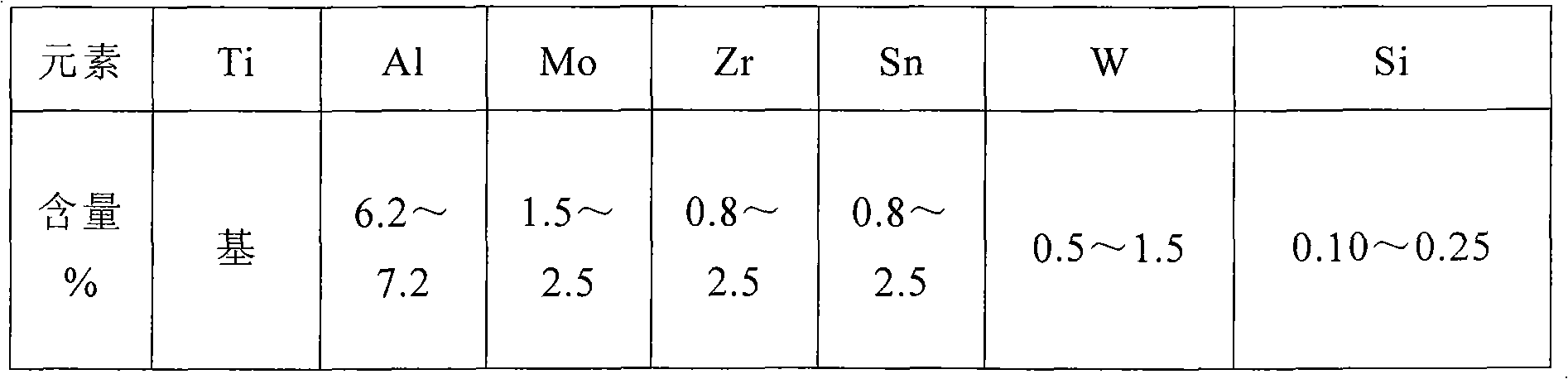

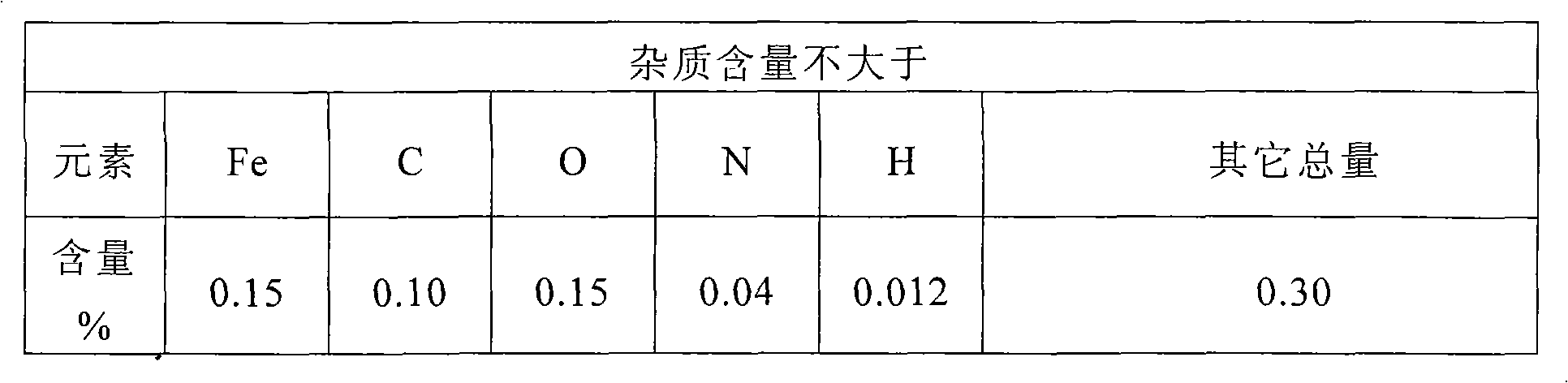

A quaternary alloy, al-mo-w-ti technology, applied in the raw material field of titanium alloy production, can solve the problems of parts failure, inclusion, etc., and achieve the effect of high yield, uniform composition and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

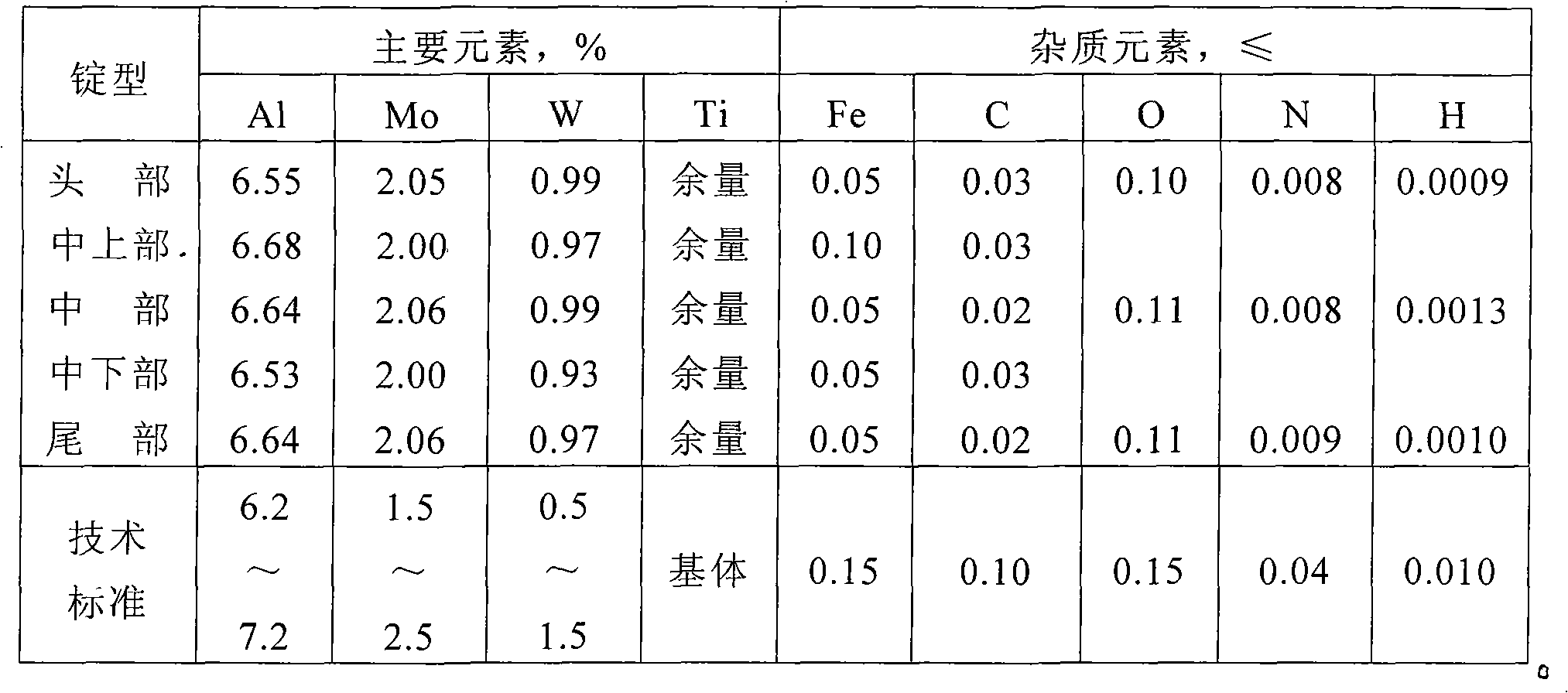

[0028] Embodiment of the present invention: firstly, metal Al and MoO powder, metal Al and WO powder are replaced by conventional thermite method to produce Mo powder and W powder, avoiding the addition of large particles of pure Mo and W; then AlO, Mo powder, W powder and sponge Ti are mixed according to a certain ratio (chemical composition weight percentage is as follows: W 12-14%, Mo 24-28%, Al 48-58%, Ti 6-10%), and melted in a vacuum induction furnace, cast After the alloy block is formed, a crusher is used to break the alloy block into small particles of ≤10mm. Finally, according to the conventional titanium alloy production process, the Al-Mo-W-Ti quaternary alloy produced by the present invention (see Table 2) is evenly mixed with sponge titanium and other alloy raw materials, and pressed together to form an electrode (φ560×150mm). Three times of vacuum self-consumption smelting to become a qualified finished ingot (φ860×2100mm).

[0029] The chemical composition det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com