Method for truncating length-controlled carbon nanotubes

A technology of carbon nanotubes and dilute nitric acid, applied in the field of preparation of nano-catalyst materials, can solve the problems of long time, lack of practical significance for large-scale application, difficult separation, etc., to achieve mild conditions, maintain physical properties, and good physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

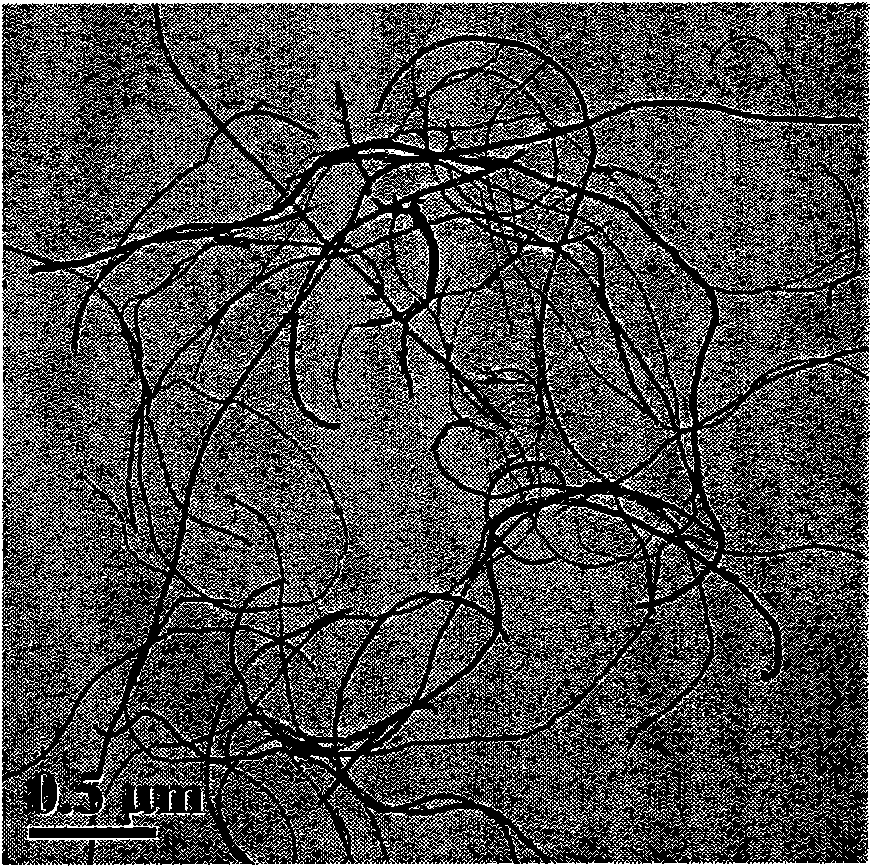

[0035] 1. Get 3 grams of carbon nanotubes and put them into a flat-bottomed flask, add 2:1 (V H2O / mass concentration 68% V HNO3 , volume ratio) of dilute nitric acid 120ml, then refluxed in an oil bath at 110°C for 5 hours, and finally filtered and washed with deionized water, and dried at 100°C for 2 hours to obtain purified carbon nanotubes with a hydrophilic surface. Electron microscope photos are attached figure 1 . It can be seen from the transmission electron microscope photos that the multi-walled carbon nanotubes cannot be truncated after being treated with dilute nitric acid, and the length of most of the multi-walled carbon nanotubes is more than 3 microns.

[0036] 2. Take 1 g of the carbon nanotubes obtained in 1, add 23.1 ml of 0.02 mol / L silver nitrate solution, then add 10 ml of water, and mix well. Then stir at a speed of 160r / min in an 80°C water bath until dry. Finally, it was dried in an oven at 100° C. for 2 hours.

[0037] 3. Heat the sample obtaine...

Embodiment 2

[0039] 1. Get 4 grams of carbon nanotubes and put them into a flat-bottomed flask, add 2:1 (V H2O / mass concentration 68% V HNO3 ) of dilute nitric acid 200ml, then refluxed at 110°C for 5 hours in an oil bath, and finally filtered and washed with deionized water, and dried at 100°C for 2 hours.

[0040] 2. Take 0.5 g of carbon nanotubes obtained in 1, add 1.16 ml of 0.08 mol / L silver nitrate solution, then add 20 ml of water and mix well. Then stir at a speed of 160r / min in an 80°C water bath until dry. Finally, it was dried in an oven at 100° C. for 2 hours.

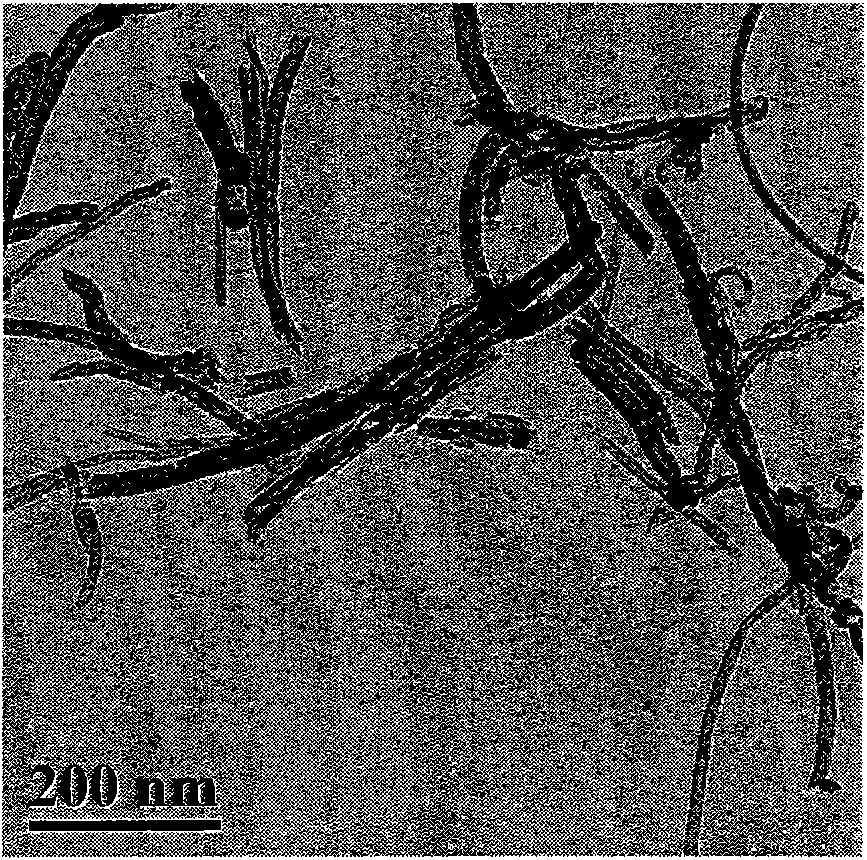

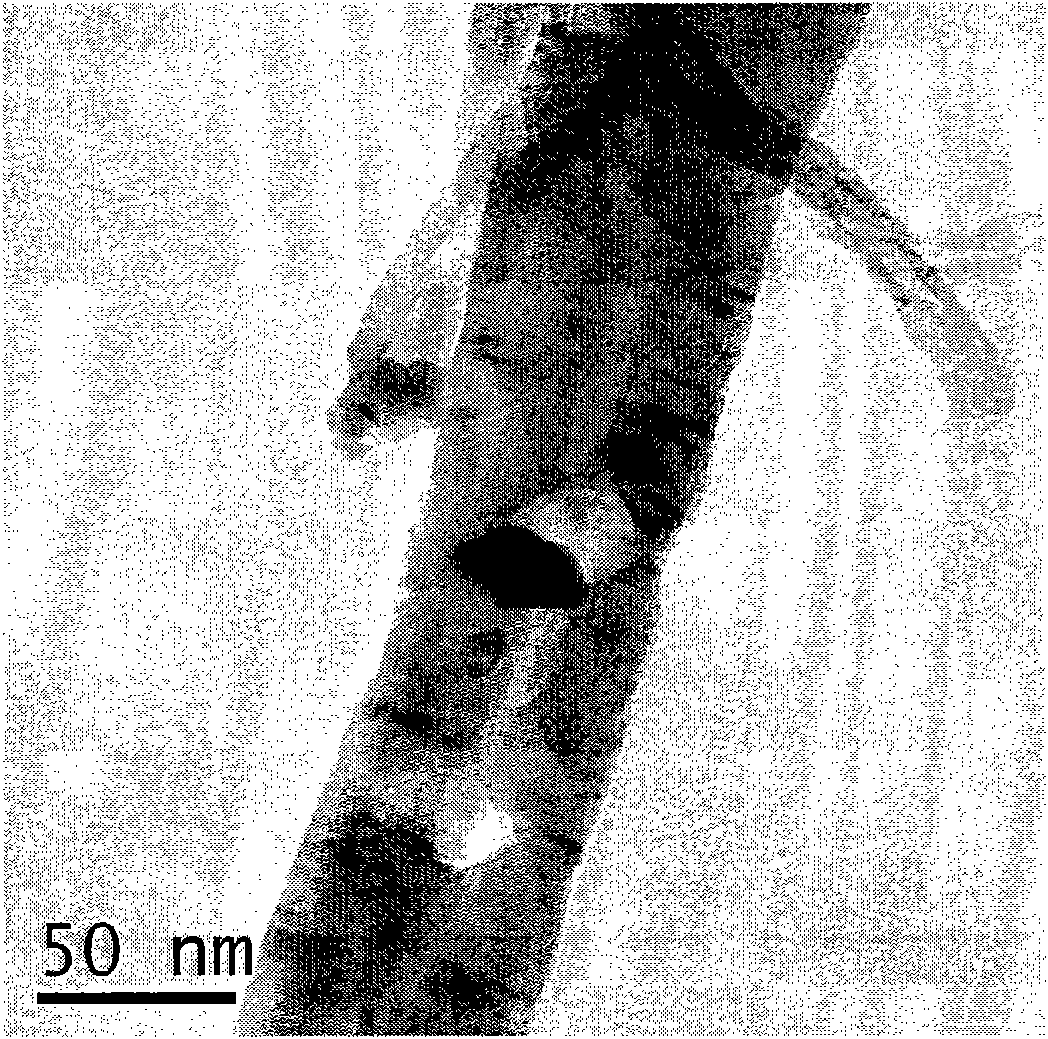

[0041] 3. Heat the sample obtained in 2 to 300°C at a rate of 2K / min in flowing He gas, then cool it down to room temperature, and then switch to 5% O 2 / He (V / V, volume percentage) mixed gas, heated to 300°C at a rate of 2K / min and maintained at this temperature for 105 minutes, and finally cooled to room temperature to obtain truncated carbon nanotubes. The overall yield of carbon nanotubes was 80%. Transmission...

Embodiment 3

[0043] 1. Get 4 grams of carbon nanotubes and put them into a flat-bottomed flask, add 2:1 (V H2O / mass concentration 68% V HNO3 ) of dilute nitric acid 200ml, then refluxed at 110°C for 5 hours in an oil bath, and finally filtered and washed with deionized water, and dried at 100°C for 2 hours.

[0044] 2. Take 0.5 g of carbon nanotubes obtained in 1, add 0.29 ml of 0.08 mol / L silver nitrate solution, then add 20 ml of water and mix well. Then stir at a speed of 160r / min in an 80°C water bath until dry. Finally, it was dried in an oven at 100° C. for 2 hours.

[0045] 3. Heat the sample obtained in 2 to 300°C at a rate of 2K / min in flowing He gas, then cool down to room temperature, and then switch to 5% O 2 / He (V / V, volume percentage) mixed gas, heated to 300°C at a rate of 2K / min and maintained at this temperature for 105 minutes, and finally cooled to room temperature to obtain truncated carbon nanotubes. The overall yield of carbon nanotubes was 93%. Transmission e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com