Woolen blanket for papermaking and manufacturing method thereof

A paper-making felt and base fabric technology, applied in papermaking, papermaking machines, textiles and papermaking, etc., can solve the problems of clogging gaps, reducing surface potential energy, affecting water permeability, etc., to prevent clogging, good water permeability, and blanket water storage The effect of empowerment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

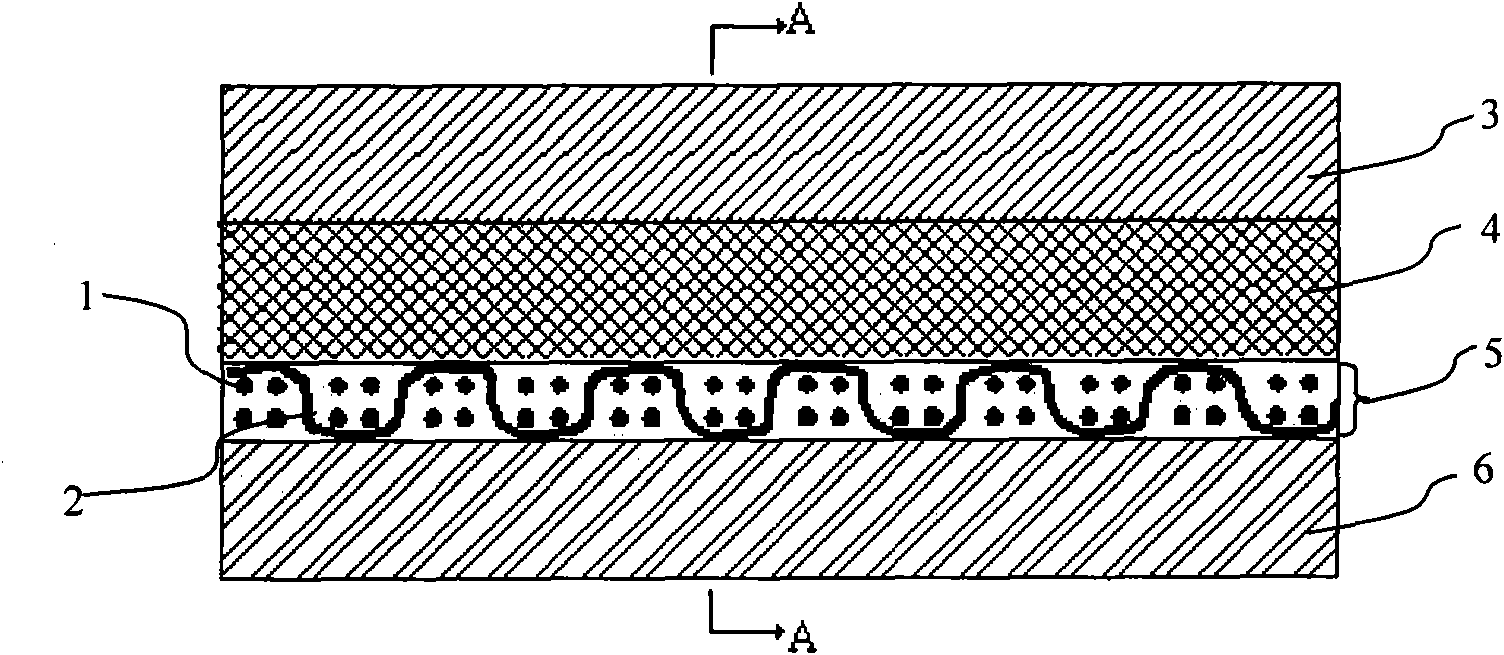

[0036] image 3 After improving the base cloth 5 in the papermaking felt of the prior art, the base cloth schematic diagram of the papermaking felt of the present invention, Figure 4 for image 3 The B-B section view.

[0037] The base fabric 5 in the papermaking felt of this embodiment is a single-layer base fabric, the warp yarns are alternately thick and thin, and the weft yarns are alternately thick and thin.

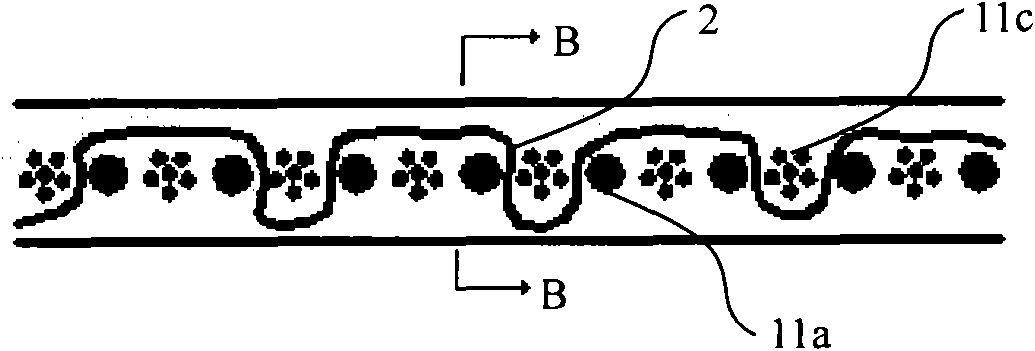

[0038] Such as image 3 As shown, warp 1 consists of root of warp 11c and The warp yarns 11a are alternately composed.

[0039] Such as Figure 4 As shown, weft yarn 2 consists of root of the weft yarn 21c and The weft yarns 21a are alternately composed.

[0040] The preparation method of present embodiment papermaking carpet is as follows:

[0041] (1) Process steps

[0042] 1. Base cloth weaving

[0043]

[0044] 2. Fiber roll manufacturing

[0045] Carding of short fibers into a web → pre-needling → fiber rolls

[0046] 3. Manufacture of nee...

Embodiment 2

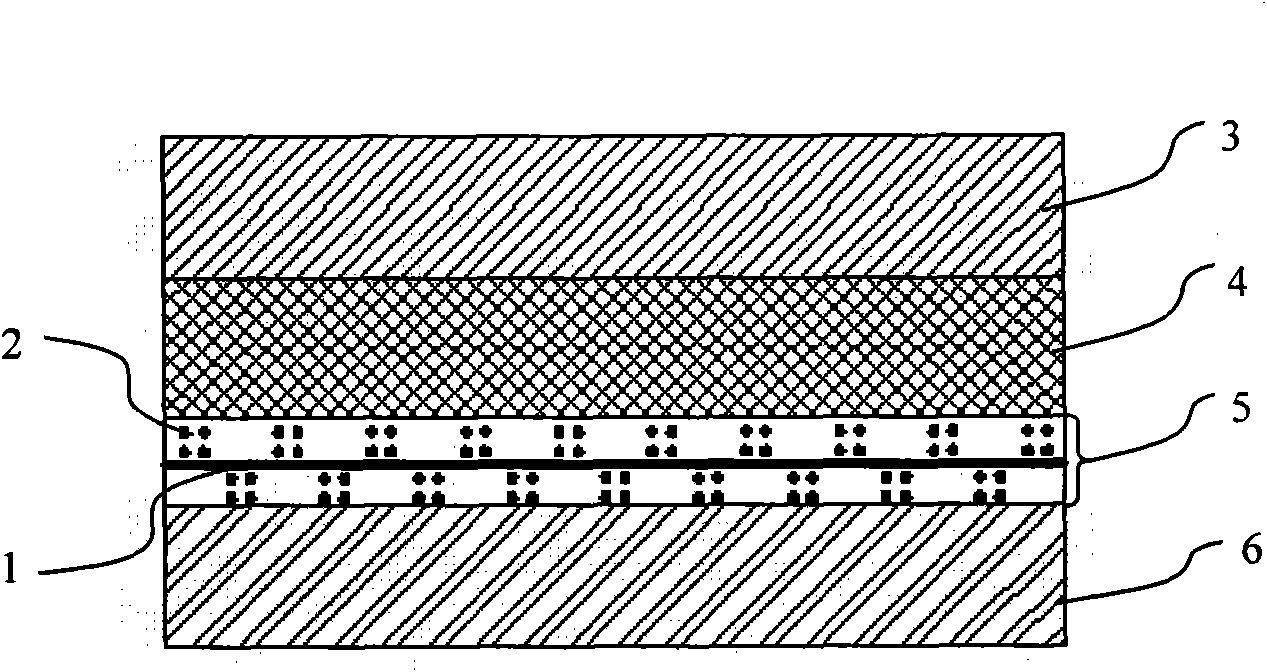

[0088] Figure 5 After improving the base cloth 5 in the papermaking felt of the prior art, the base cloth schematic diagram of the papermaking felt of the present invention, Figure 6 for Figure 5 C-C section view.

[0089] The base fabric 5 in the papermaking felt of this embodiment is a double-layered base fabric, the warp yarns are alternately thick and thin, and the weft yarns are alternately thick and thin.

[0090] Such as Figure 5 As shown, warp 1 consists of root of warp 12c and The warp yarns 12a are formed alternately.

[0091] Such as Figure 6 As shown, weft yarn 2 consists of root of weft yarn 22c and The weft yarns 22a are alternately formed.

Embodiment 3

[0093] Figure 7 After improving the base cloth 5 in the papermaking felt of the prior art, the base cloth schematic diagram of the papermaking felt of the present invention, Figure 8 for Figure 7 D-D cutaway view.

[0094] Such as Figure 7 As shown, the base cloth 5 in the papermaking felt of this embodiment is a multi-layer base cloth structure, and a single-layer base cloth is superimposed by a single-layer base cloth, wherein:

[0095] The single-layer base fabric of the upper layer: the warp yarn 13b is Nylon yarn with a warp density of 90 threads / 10CM. The warp yarn thickness of the single-layer base cloth of the upper layer is the same.

[0096] The single layer base fabric of the lower layer: warp yarn 1 by Nylon yarn warp 13a with ×6 polyamide yarn warp yarns 13c are formed alternately, and the warp density is 90 threads / 10CM.

[0097] Such as Figure 8 Shown:

[0098] The single-layer base fabric of the upper layer: the weft yarn 23b is Nylon yarn w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com