Process for producing feed-grade zinc lactate

A production process and feed-grade technology, which is applied in the production field of zinc lactate, can solve the problems of insufficient purity and zinc content of zinc lactate finished products, reduce raw material utilization rate, increase production cost, etc., and achieve high-efficiency palatability and low production cost , The effect of environmental protection in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

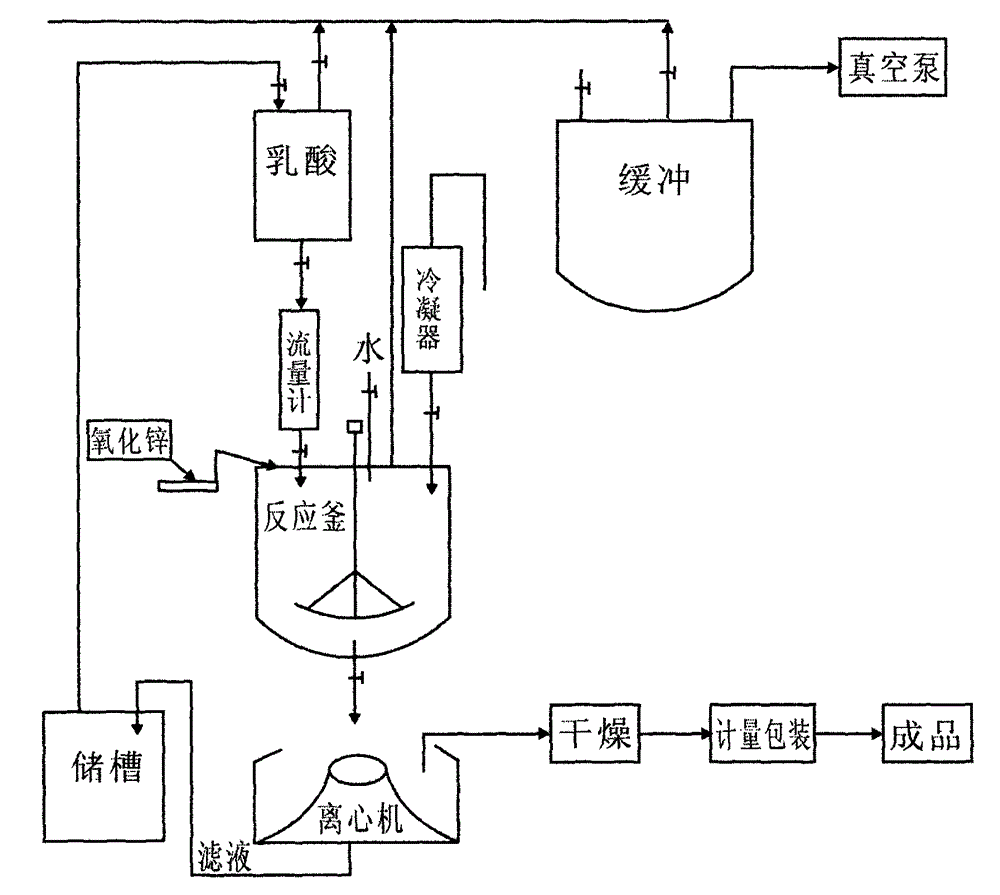

[0020] The present invention will be further described in detail below in conjunction with the drawings:

[0021] As shown in the drawings, the production process of the present invention is as follows: metering each raw material into the reaction kettle-direct chemical reaction-cooling-centrifugal separation-drying-packaging-finished product. In the centrifugal separation process, the separated mother liquor is introduced into the storage tank; the mother liquor in the storage tank is then introduced into the reaction kettle for chemical reaction, so that the mother liquor is recycled.

[0022] The zinc oxide, lactic acid and water in the attached drawing are all raw materials. Zinc oxide uses feed-grade zinc oxide with a purity of 98% and above; lactic acid uses food-grade DL-lactic acid with a purity of 80% or above. Water is edible water. Zinc oxide It is solid, so it adopts quantitative weighing and adding method, lactic acid and water are both liquid, so only need to be contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com