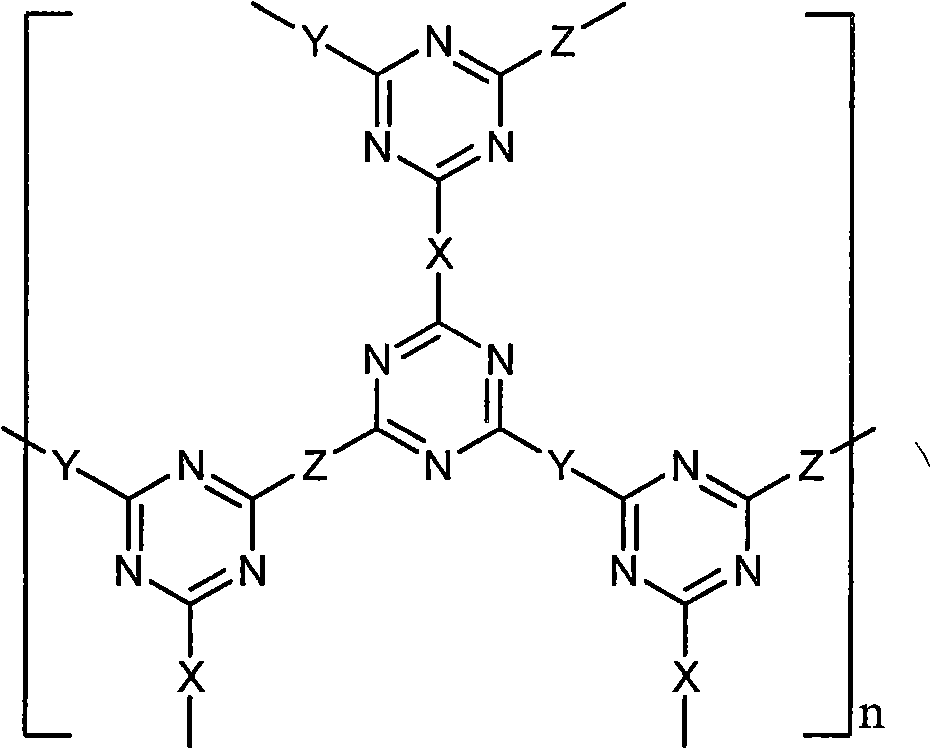

Macromolecular intumescent flame resistance carbonizing agent with branching and crosslinking structure and preparation method and application thereof

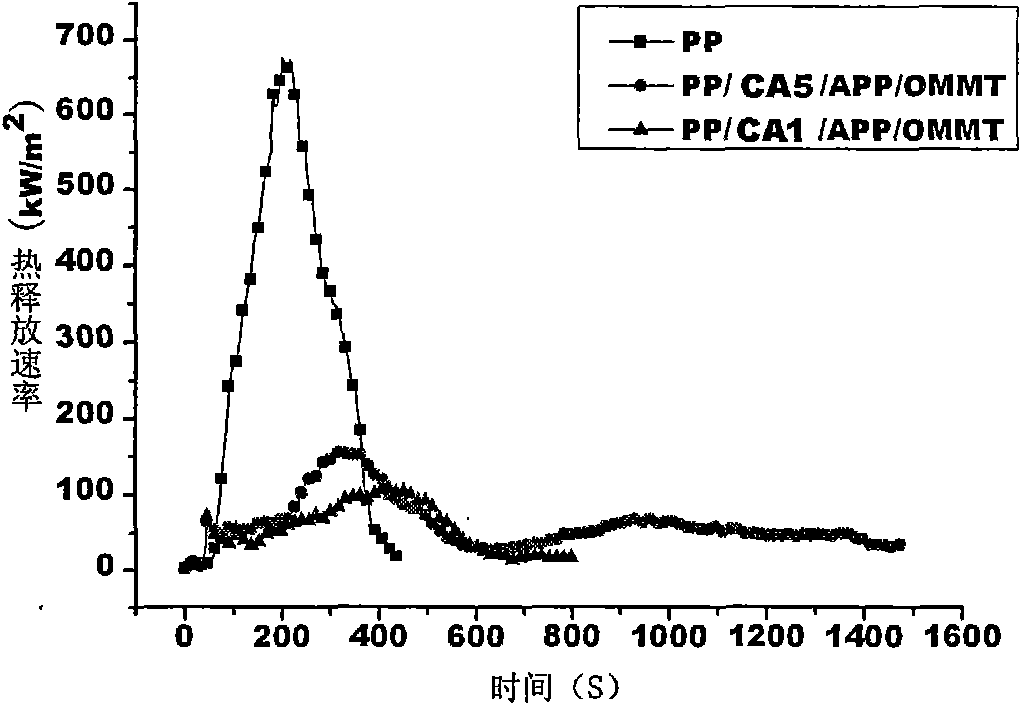

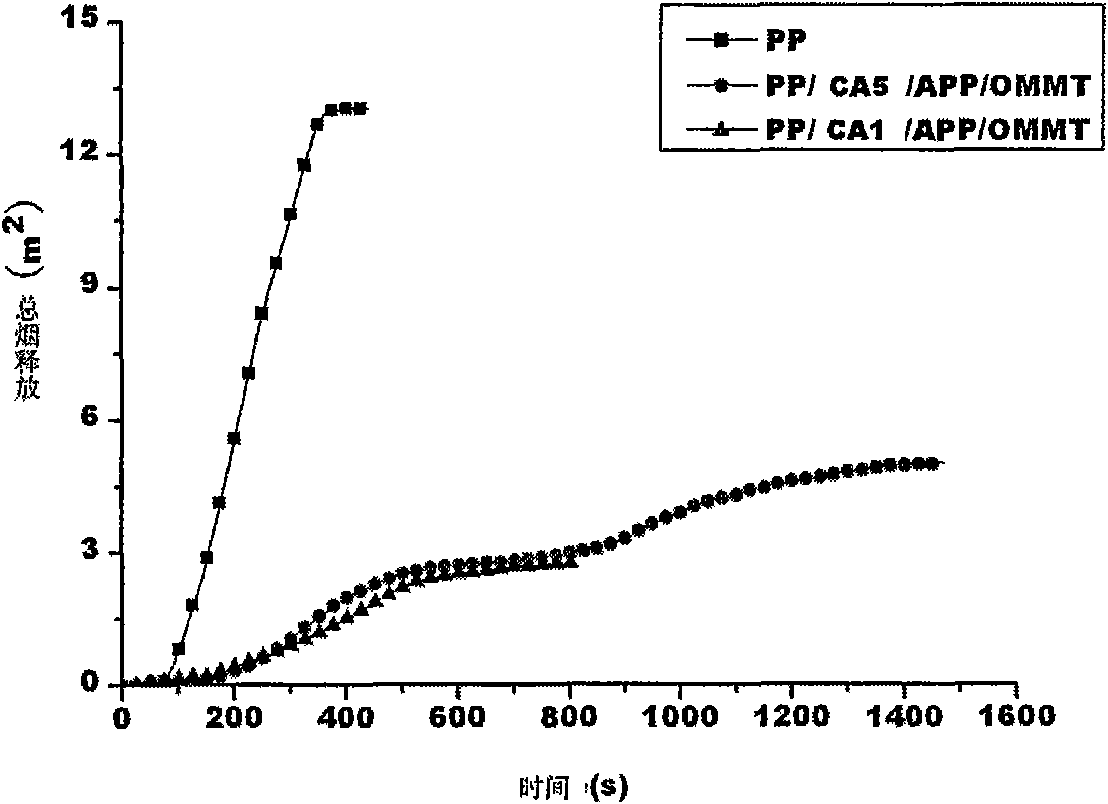

An intumescent flame retardant and intumescent flame retardant technology, which is applied in the direction of fireproof coatings, etc., can solve the problems that the mechanical properties of materials are also greatly affected, the flame retardant efficiency is greatly affected, and the compatibility of polymers is poor, so as to reduce the maximum heat release Speed, excellent flame retardant effect, good foaming and charcoal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 1mol of cyanuric chloride into 400mL of water and stir to disperse the cyanuric chloride evenly, then add 1mol of diethylenetriamine and the aqueous solution made of 40g of NaOH dropwise at the same time at a temperature of 0-5°C, the speed of dropping the NaOH solution should be Control the pH of the reaction system at 6-7, and react for 2 hours; after raising the temperature of the reaction system to 30°C, continue to stir while adding 1mol of diethylenetriamine and an aqueous solution prepared with 40g of NaOH dropwise, and add dropwise The speed of the NaOH solution should be such that the pH of the reaction system is controlled at 6-7, and the reaction lasts for 8 hours; after the temperature of the reaction system is raised to 90°C, 1mol of diethylenetriamine and 40g of NaOH are added dropwise while stirring. Aqueous solution, the speed of adding NaOH solution dropwise should make the pH of the reaction system be controlled at 6-8, and react for 7 hours in tota...

Embodiment 2

[0042] Add 1mol cyanuric chloride to 400mL water and stir to disperse cyanuric chloride evenly, then add 0.5mol diethylenetriamine and an aqueous solution made of 56g KOH dropwise at a temperature of 5-10°C at the same time, the speed of dropping KOH solution The pH of the reaction system should be controlled at 5-7, and the total reaction time is 3 hours; after the temperature of the reaction system is raised to 40°C, 0.5mol of diethylenetriamine and an aqueous solution prepared with 56g of KOH are added dropwise to it while stirring. The speed of dropping the KOH solution should be such that the pH of the reaction system is controlled at 5-7, and the reaction lasts for 10 hours; after raising the temperature of the reaction system to 90°C, continue to add 0.5mol of diethylenetriamine dropwise while stirring and add 56g of KOH For the prepared aqueous solution, the rate of dropping the KOH solution should be such that the pH of the reaction system is controlled at 6-8, and the...

Embodiment 3

[0045] Add 1mol cyanuric chloride into 400mL water / acetone (volume ratio 1:1) mixed solution and stir to disperse cyanuric chloride evenly, then dropwise add 0.5mol diethylenetriamine and use 53g Na 2 CO 3 Aqueous solution was added dropwise with Na 2 CO 3 The speed of the solution should be such that the pH of the reaction system is controlled at 5-7, and the total reaction is 3 hours; after the temperature of the reaction system is raised to 50°C, 0.5mol of diethylenetriamine and 53g of Na 2 CO 3 Aqueous solution was added dropwise with Na 2 CO 3 The speed of the solution should be such that the pH of the reaction system is controlled at 5-7, and the total reaction time is 11 hours; after the temperature of the reaction system is raised to 75°C, 0.5mol diethylenetriamine is added dropwise while stirring and 53g Na 2 CO 3 Aqueous solution was added dropwise with Na 2 CO 3 The speed of the solution should be such that the pH of the reaction system is controlled at 6-8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com