Hydrothermal synthesis method of LuO(OH) nanorods and Lu2O3 nanorods luminescent powder

A technology of hydrothermal synthesis and nanorods, applied in chemical instruments and methods, nanotechnology, luminescent materials, etc., can solve problems such as difficult particle aspect ratio regulation, and achieve the effect of low experimental equipment requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

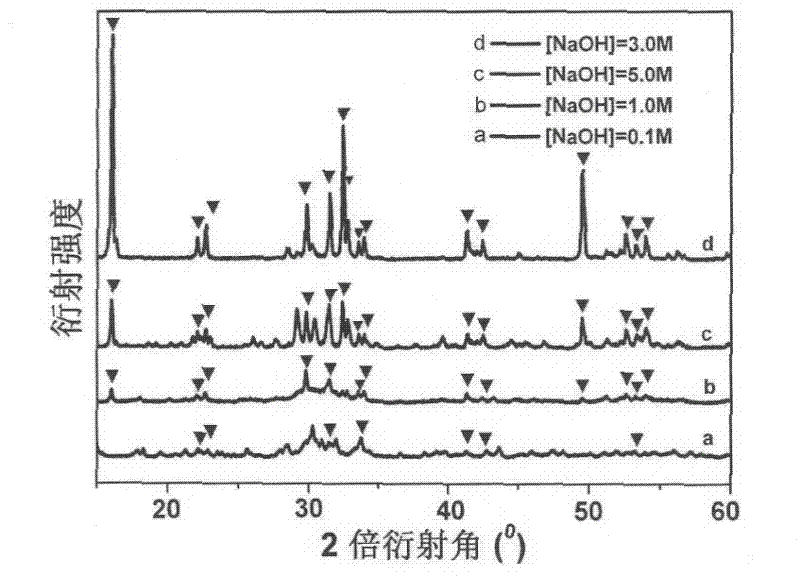

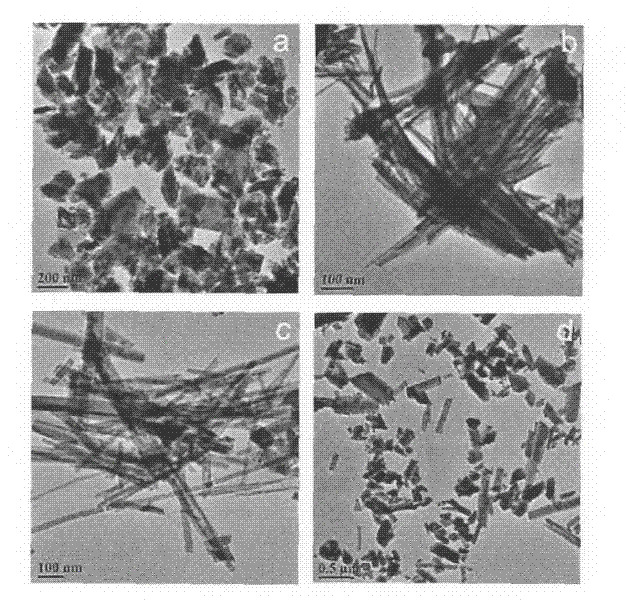

[0039] Embodiment 1: Preparation of LuO(OH) nanorods

[0040] (1), dissolve commercial lutetium oxide powder and europium oxide powder with concentrated nitric acid, then dilute to Lu(NO 3 ) 3 The concentration is 0.927mol / L, Eu(NO 3 ) 3 The concentration is 0.916mol / L. Measure 2.0ml of Eu(NO 3 ) 3 The solution was added to 30.2mlLu(NO 3 ) 3 In the solution, the molar ratio Eu / Lu in the mixed solution was 6.0%.

[0041] (2) Under the condition of vigorous stirring with a magnetic stirrer, slowly add the prepared mixed solution dropwise into 40ml of lye containing 7.0g of NaOH, a white precipitate is formed rapidly, keep stirring for 30min to make the solution fully react.

[0042] (3), filter the white precipitate with a Buchner funnel, wash it repeatedly with deionized water, remove the impurity ions on the precipitate, pour it into a liner with a volume of 100ml, add deionized water, and keep the filling rate at 70 %, then add an appropriate amount of NaOH, stir and...

Embodiment 2

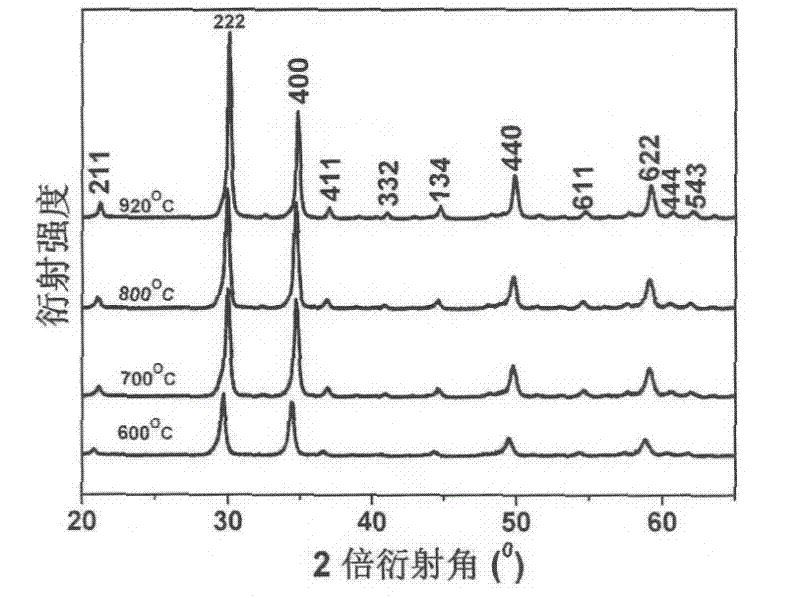

[0046] Example 2: Lu 2 o 3 Preparation of Nanorod Luminescent Powder

[0047] (1), dissolve commercial lutetium oxide powder and europium oxide powder with concentrated nitric acid, then dilute to Lu(NO 3 ) 3 The concentration is 0.927mol / L, Eu(NO 3 ) 3 The concentration is 0.916mol / L. Measure 2.0ml of Eu(NO 3 ) 3 The solution was added to 30.2mlLu(NO 3 ) 3 In the solution, the molar ratio Eu / Lu in the mixed solution was 6.0%.

[0048] (2) Under the condition of vigorous stirring with a magnetic stirrer, slowly add the prepared mixed solution dropwise into 40ml of lye containing 7.0g of NaOH, a white precipitate is formed rapidly, keep stirring for 30min to make the solution fully react.

[0049] (3), filter the white precipitate with a Buchner funnel, wash it repeatedly with deionized water, remove the impurity ions on the precipitate, pour it into a liner with a volume of 100ml, add deionized water, and keep the filling rate at 70 %, then add an appropriate amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com