Method for simultaneously preparing furfuryl alcohol and furoic acid on the basis of bipolar membrane technology

A bipolar membrane and furfuryl alcohol technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems such as low product yield, high price, and poor selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

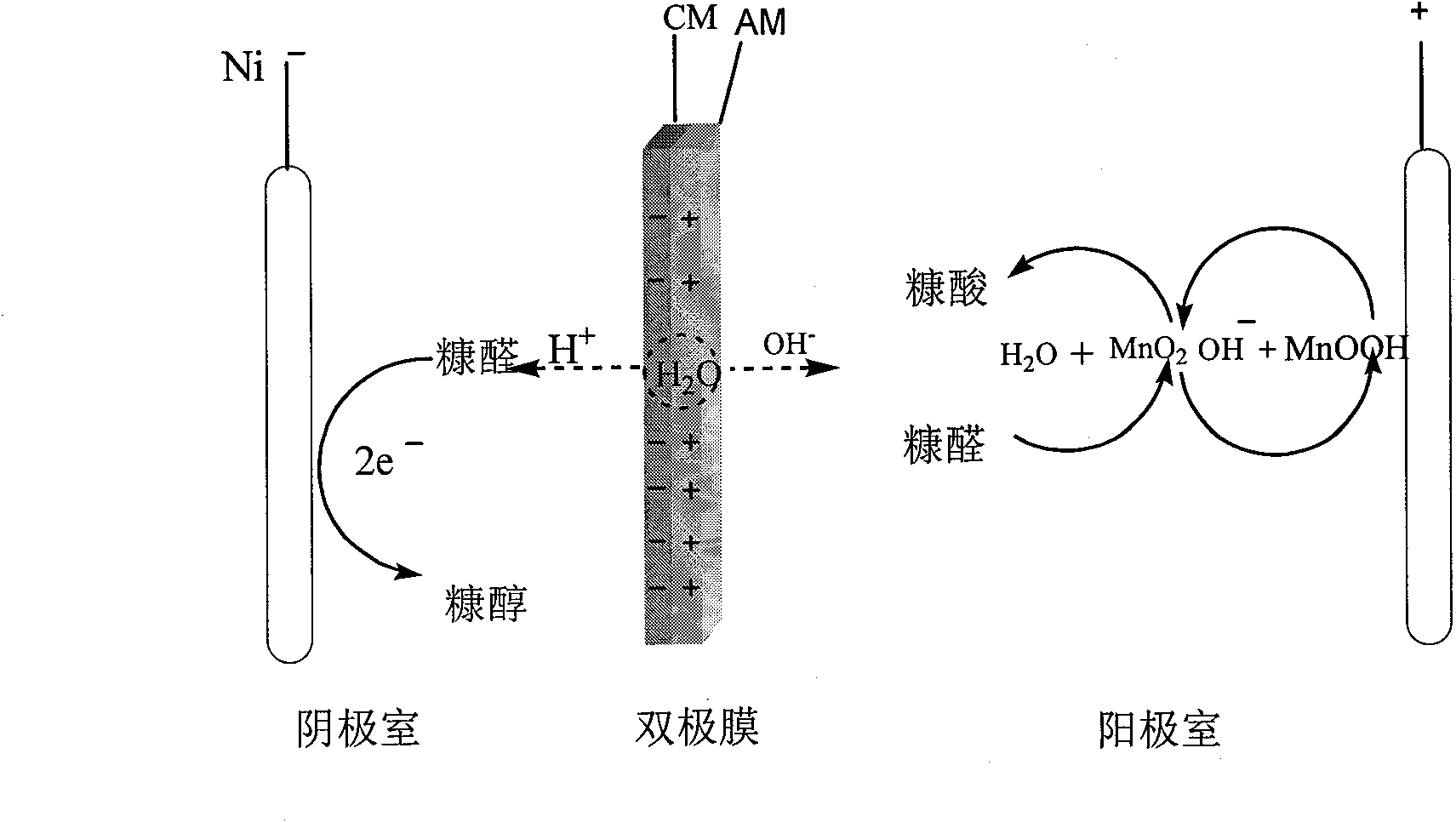

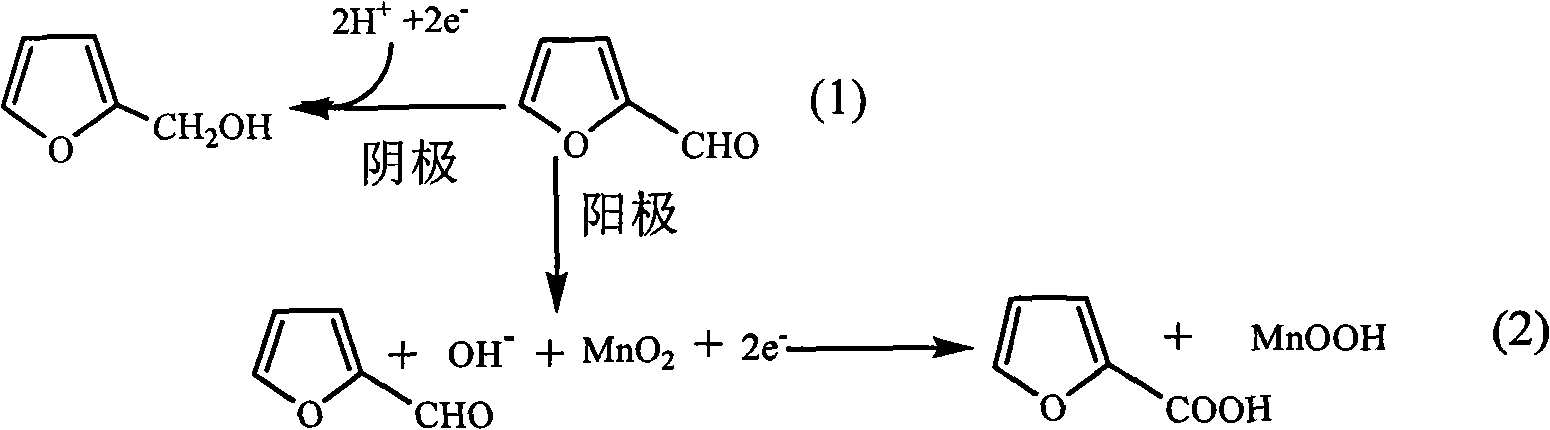

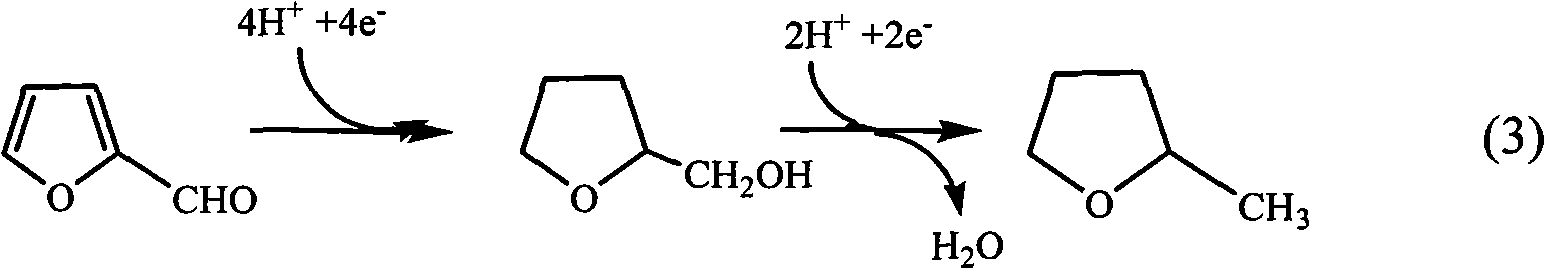

Method used

Image

Examples

Embodiment 1

[0028] Inject 3.0mol·L into the cathode chamber -1 solution of furfural tetrabutylammonium bromide. Add 100g / L MnO in the anode chamber 2 , A mixed solution of 400g / L NaOH and 300mL furfural. Place the ultrasonic oscillator in the anode chamber of the electrolytic cell, the temperature of the electrolyte is 30°C, and the current density is 30mA·cm -2 . The electrolysis time was 50 minutes. The yield of furfuryl alcohol in the cathode compartment is 84%, and the current efficiency is 75%. The yield of furoic acid in the anode compartment was 87%. The current efficiency is 70%, and the electrolyzer voltage is 2.8V.

Embodiment 2

[0030] The electrolyte temperature is 45°C, and the current density is 70mA·cm -2 .

[0031] Inject 3.0mol·L into the cathode chamber -1 solution of furfural tetrabutylammonium bromide. Add 400g / L MnO in the anode chamber 2 , A mixed solution of 400g / L NaOH and 300mL furfural. Place the ultrasonic oscillator in the anode chamber of the electrolytic cell, and the electrolysis time is 30 minutes. The yield of furfuryl alcohol in the cathode compartment is 87%, and the current efficiency is 70%. The yield of furoic acid in the anode compartment was 82%. The current efficiency is 65%, and the electrolyzer voltage is 2.2V.

Embodiment 3

[0033] Electrolyte temperature 60°C, current density 70mA·cm -2 . Nafion single membrane is used as the diaphragm of the electrolyzer.

[0034] The electrolyte composition and process conditions of the anode chamber and the cathode chamber are the same as in Example 1. The electrolysis time was 20 minutes. The yield of furfuryl alcohol in the cathode compartment was 23%. The yield of furoic acid in the anode compartment is 45%, and the voltage of the electrolytic cell is 3.0V.

[0035] When Nafion single membrane is used as the diaphragm of the electrolyzer, because furfural and MnO 2 After the reaction, the incomplete hydrolysis to furoic acid must be carried out in an alkaline environment (Equation 2). In the anode chamber of the Nafion membrane cell, as the electrolysis time increases, the anode causes OH due to the oxygen evolution side reaction (equation 3) - The concentration decreased due to consumption, and the yield of furoic acid also decreased at a relatively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com