Negative temperature coefficient polymer composite material for temperature sensing cable and preparation method

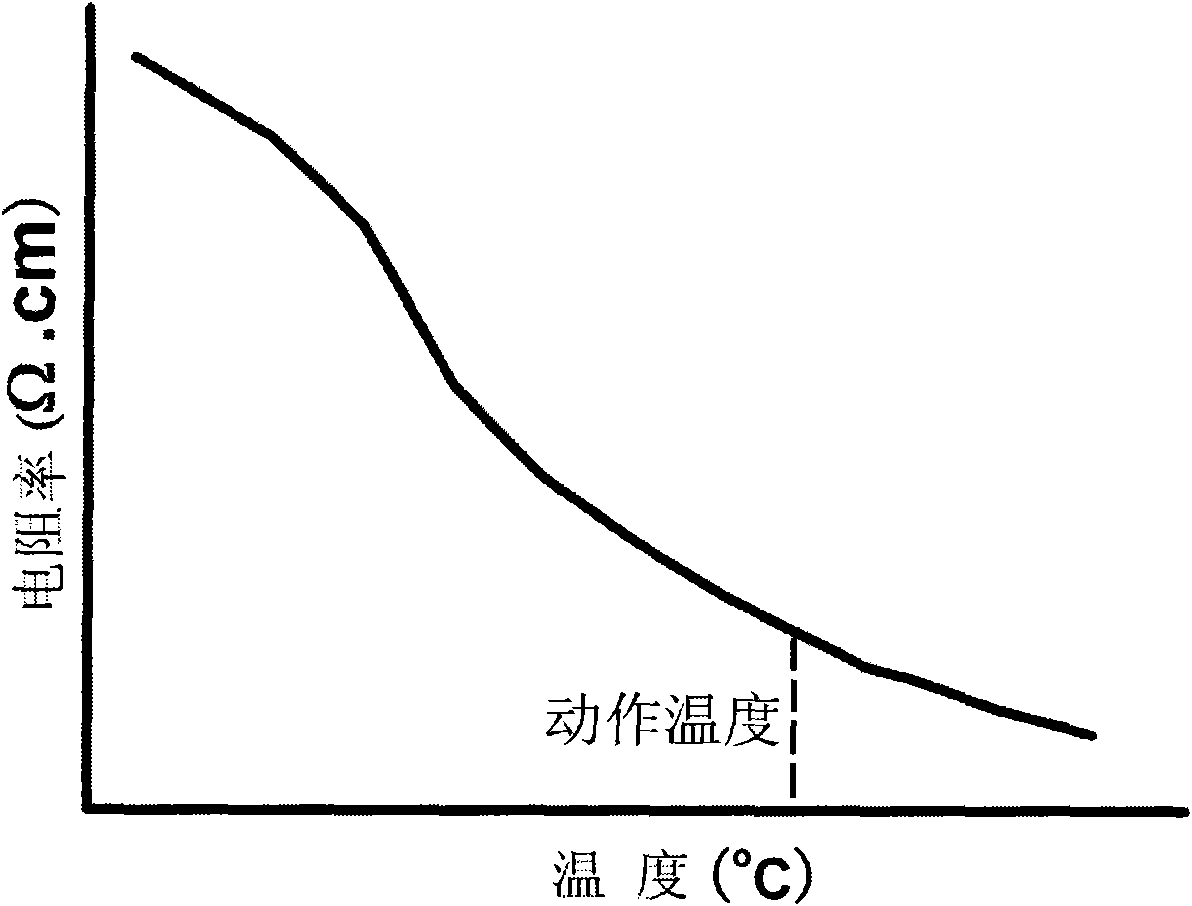

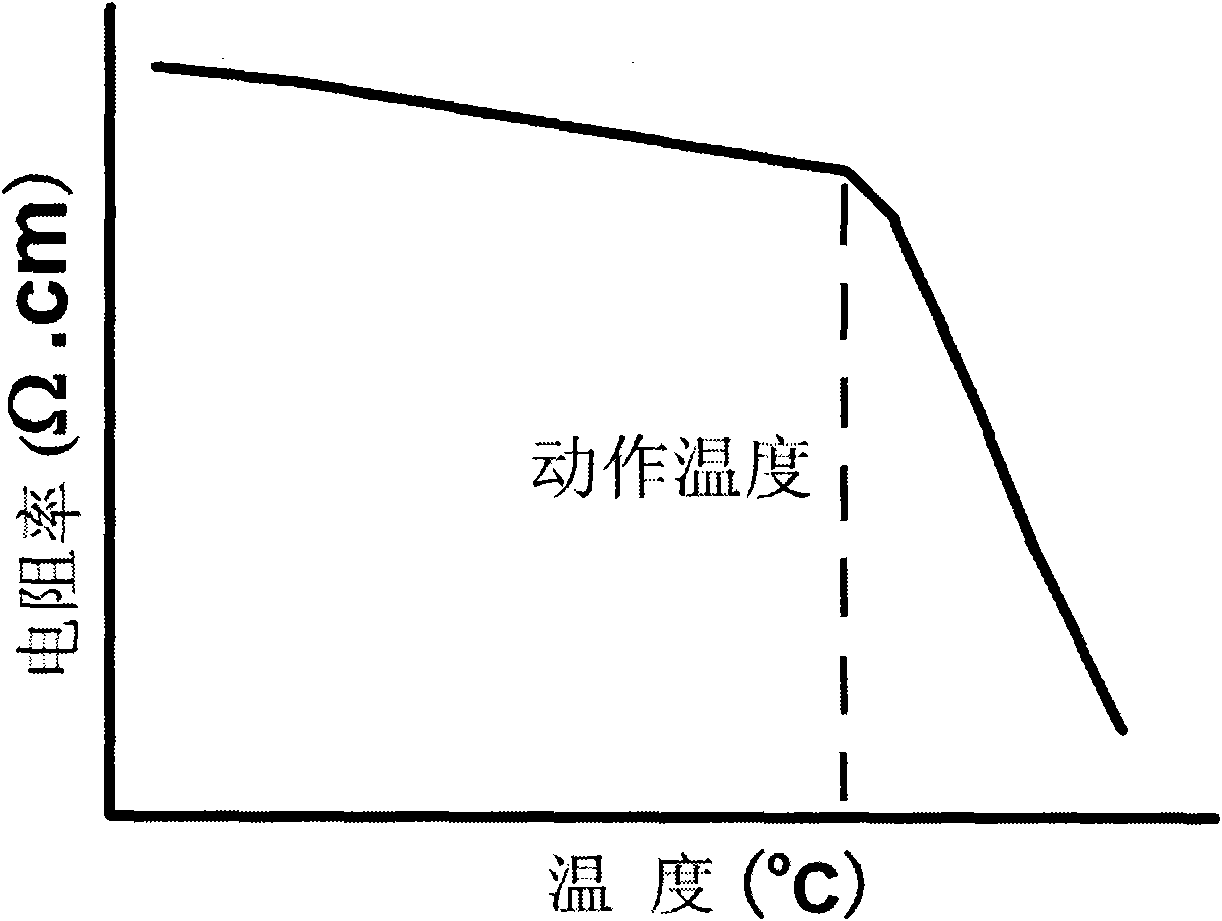

A negative temperature coefficient and composite material technology, which is applied in the field of negative temperature coefficient of resistance polymer composite materials and preparation, and the preparation of polymer functional composite materials, can solve the problems of poor repeatability, non-reusable, insensitive alarm, etc. Small, reproducible and sensitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1. 100 parts by weight of natural rubber, 5 parts by weight of ethylene-vinyl acetate copolymer, 10 parts by weight of acetylene carbon black, 1 part by weight of sulfur, and 3 parts by weight of paraffin are compounded in an open mill at 170 ° C and then formed , kept at 70°C for 20 hours, cooled to room temperature, and then chemically cross-linked to measure the temperature-resistance characteristics. The room temperature resistivity was 9.1×10 8 Ω·cm, resistivity before operating temperature is 8.7×10 8 Ω·cm, the resistivity after operating temperature is 2.7×10 7 Ω·cm.

[0073] Embodiment two, 100 parts of ethylene-propylene rubber, 10 parts by weight of polyethylene wax, 8 parts by weight of conductive carbon black, 5 parts by weight of 2,5-dimethyl-2,5-two (tert-butyl peroxy) hexane , formed after compounding in a twin-screw extruder at 90°C, kept at 80°C for 30 hours, cooled to room temperature, and then chemically cross-linked to measure the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com