Ultraviolet light curable coating for protecting steel materials free of preliminary treatment

A technology for curing coatings and steel materials, used in polyester coatings, anti-corrosion coatings, polyamide coatings, etc., to improve production efficiency, reduce processes, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

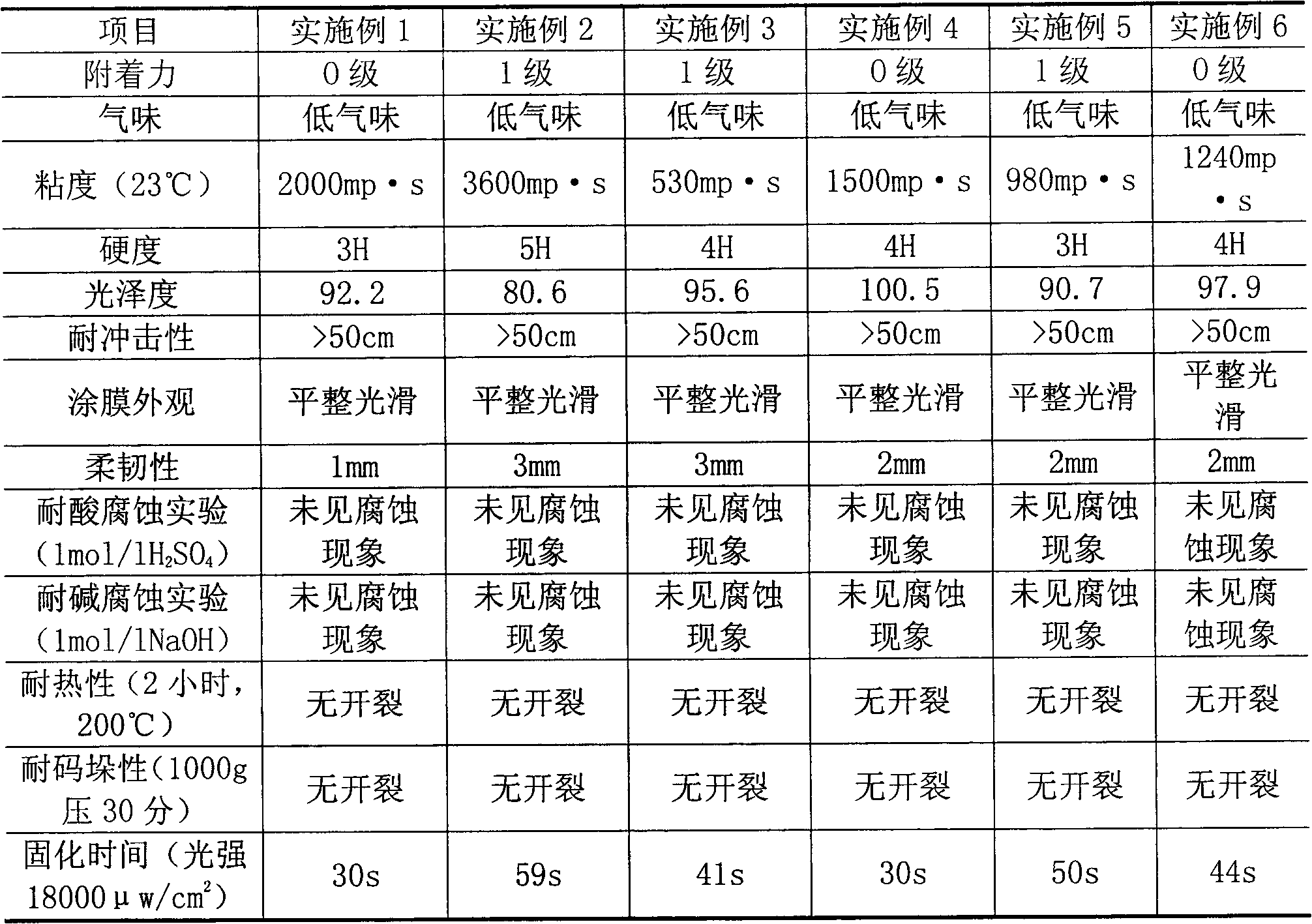

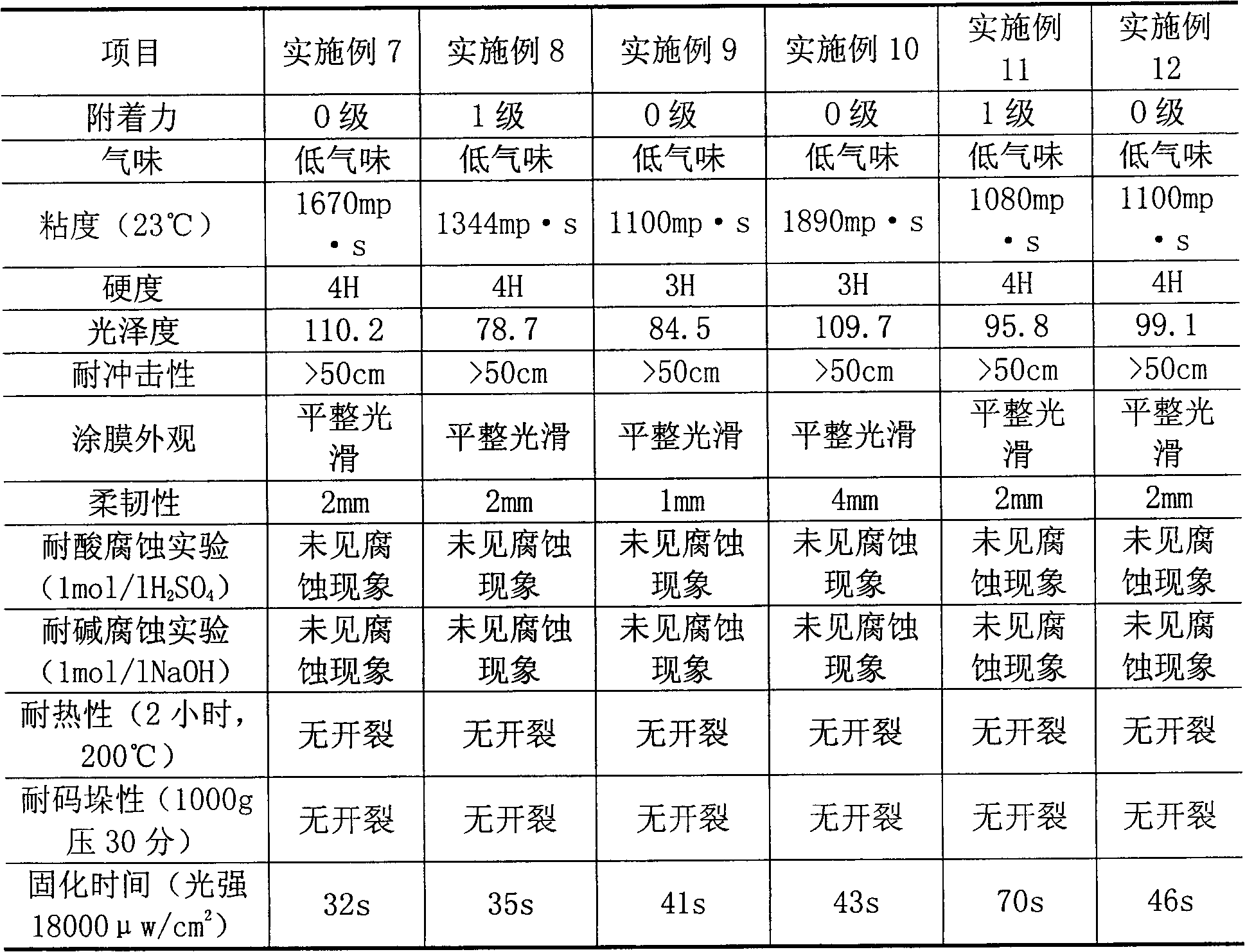

Examples

example 1

[0083] Polyester acrylate: CN704: 54%

[0084] Reactive diluents: TMPTA: 12%; PO2NPGDA: 21%; HEMA: 4%

[0085] Photoinitiator: BP: 2%; 1173: 3%

[0086] Co-initiator: CN373: 1%

[0087] Adhesion Promoter: CD9051: 3%

example 2

[0089] Polyester acrylate: CN704: 35%

[0090] Active oligomer: 6145: 27%

[0091] Reactive diluent: TMPTA: 11%; PO2NPGDA: 8%; HEMA: 5%

[0092] Photoinitiator: BP: 2%; 1173: 3%

[0093] Co-initiator: CN381: 1%

[0094] Adhesion Promoter: CD9051: 8%

example 3

[0096] Polyester acrylate: CN704: 20%

[0097] Active oligomer: 6116: 26%

[0098] Reactive diluent: TMPTA: 17% PO2NPGDA: 23%; HEMA: 4%

[0099] Photoinitiator: BP: 2%; 1173: 3%

[0100] Co-initiator: CN371: 1%

[0101] Adhesion Promoter: CD9051: 4%

[0102] On this basis, add defoamer HX-2000: 0.2% and leveling agent BYK-373: 0.2%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com