Preparation method of high-performance supported metal silicide catalyst and application thereof

A metal silicide, supported technology, applied in the field of catalysis science and technology, can solve the problem of not synthesizing high-performance and high-dispersion loaded silicide catalytic materials, and achieve excellent catalytic activity and selectivity, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

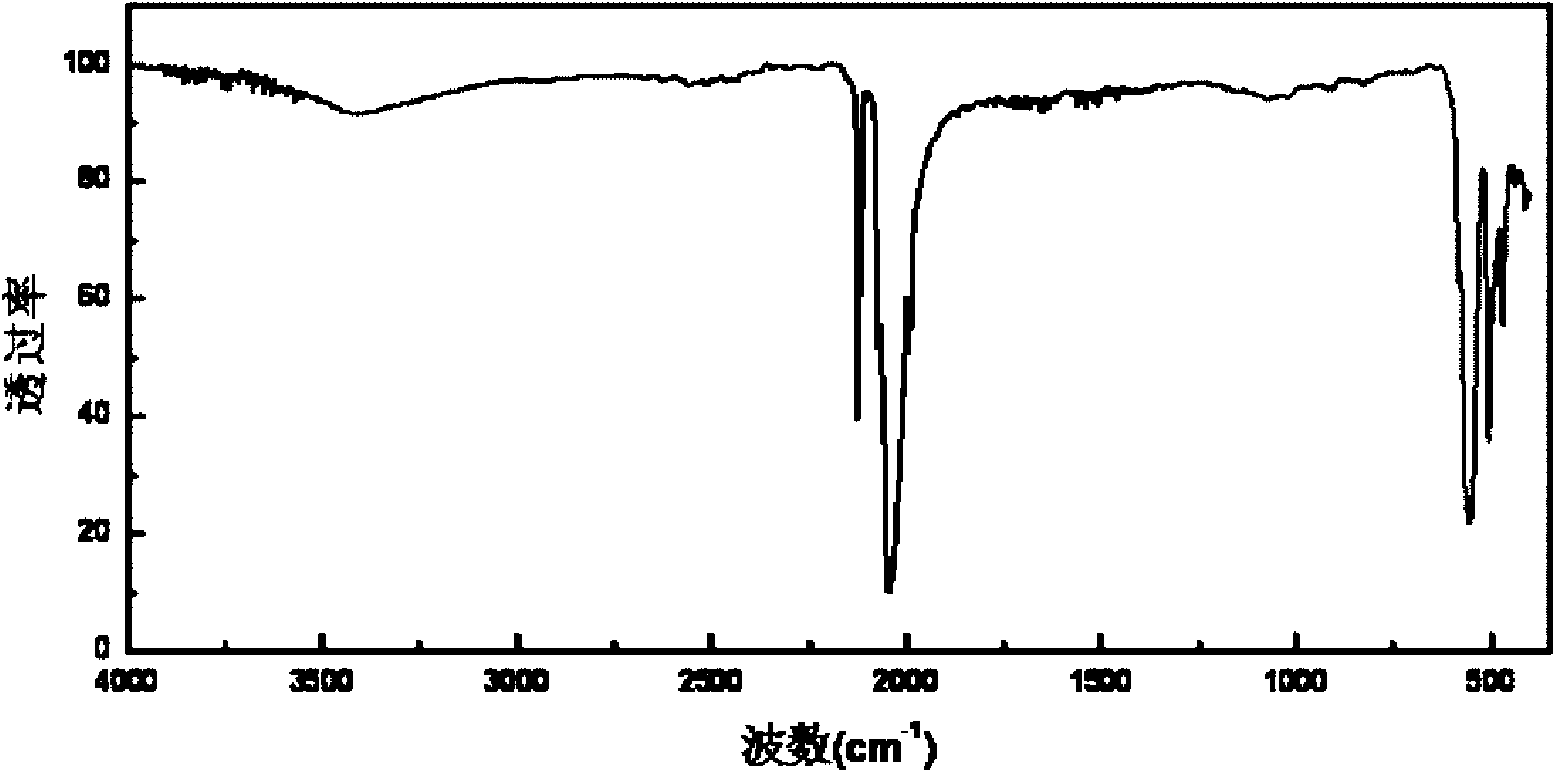

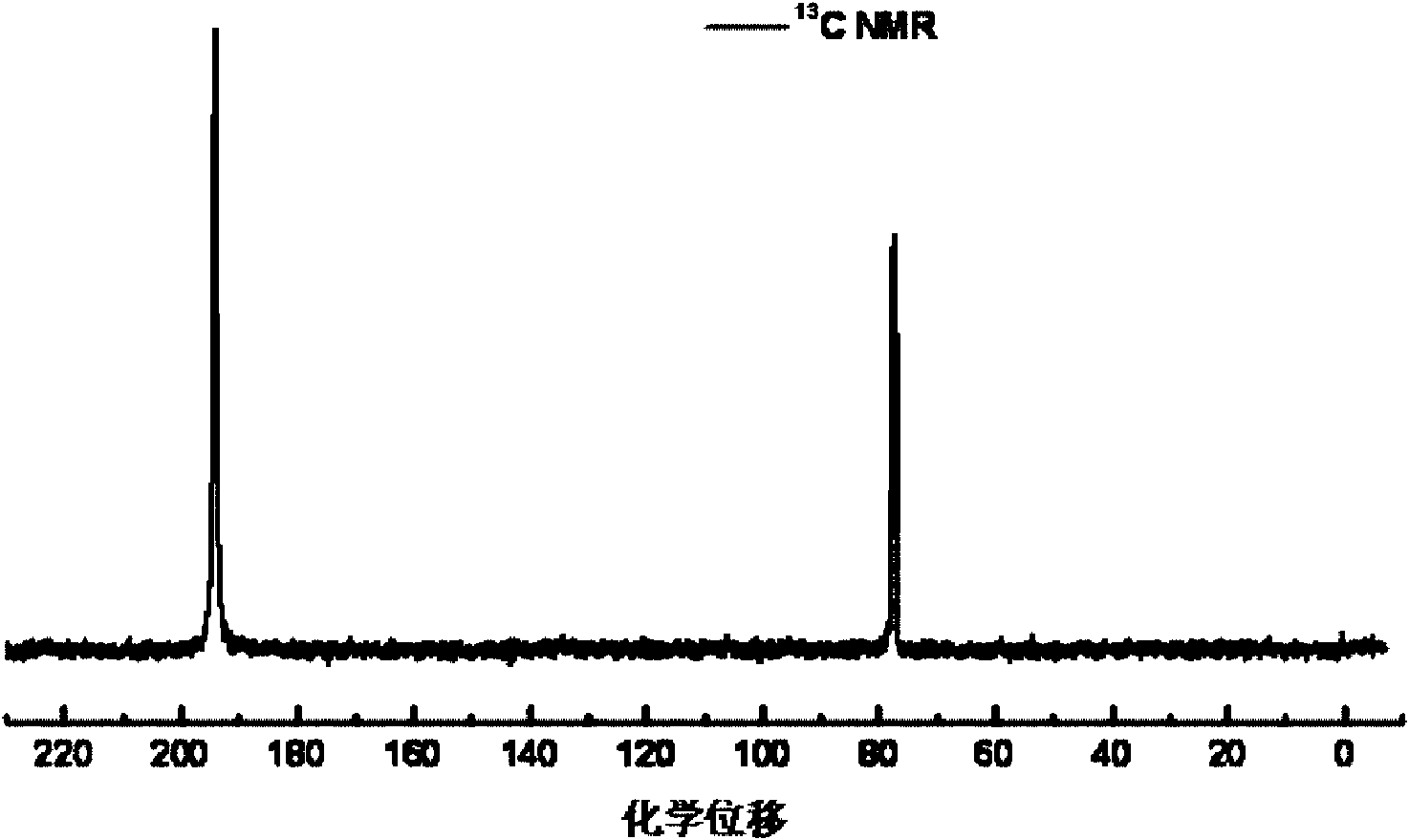

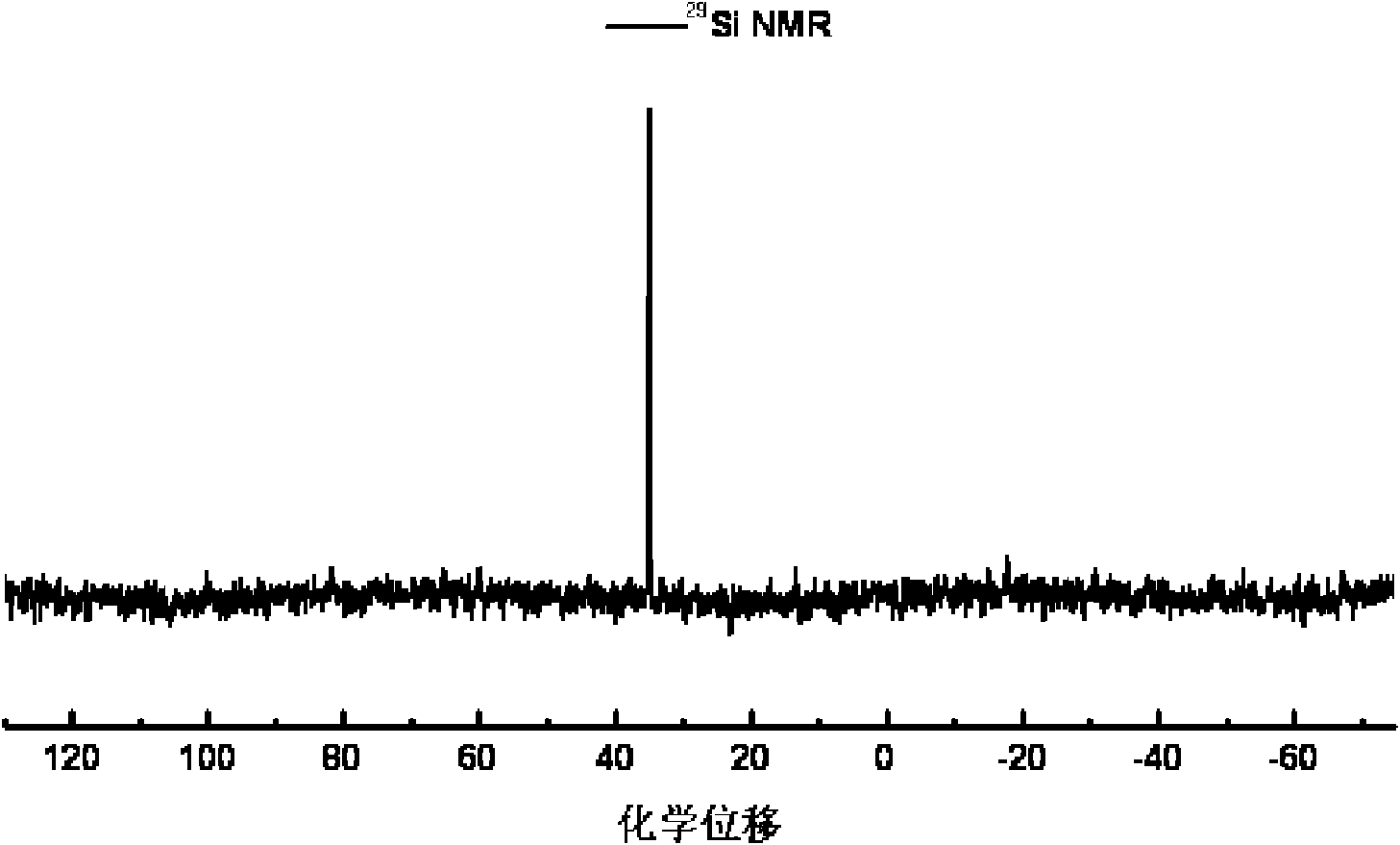

[0025] Weigh 3.0gCo 2 (CO) 8 Add to the glass bottle, take 13.5g SiHCl 3 Add it into a glass bottle and mix, stir and react for two hours at low temperature. After removing excess organic silicon compound at room temperature, the product is gray brown powder. Move it into a sublimation device, heat and sublimate, and you can see yellow needle-like crystals Generated, took out and weighed 3.65g, the yield was 70%, and sealed for storage.

Embodiment 2

[0027] Weigh 1.0gFe 3 (CO) 12 and 13.5g SiHCl 3 , at N 2 Added to the autoclave under protection. Put the autoclave into an oil bath, heat to 120°C, and keep the temperature constant for 36 hours. Then remove the excess organosilicon compound to obtain a yellow powder, put it into the sublimation device, heat and sublimate, you can see light yellow needle-shaped crystals, and continue to sublimate to get light green granular crystals, take it out and weigh 0.3g, the yield is 60%, and it is sealed and stored.

Embodiment 3

[0029] Weigh 0.5 g of SiO pretreated at 500 °C in a muffle furnace 2 Carrier, placed in a fluidized bed reactor, weighed 0.15g of the metal organocobalt silicon compound precursor, argon as the carrier gas, sublimated at 40°C, and the precursor was loaded on SiO 2 On the thermal decomposition of 500 ℃ to obtain the supported metal cobalt silicide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com