Fluoroelastomer coating with high fluorine content and low-temperature solidification

A technology of fluoroelastomer and fluorine content, applied in the direction of coating, etc., can solve the problems of consumption, difficulty in realization and popularization and application, etc., and achieve the effects of expanding application range, simplifying construction conditions and processes, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

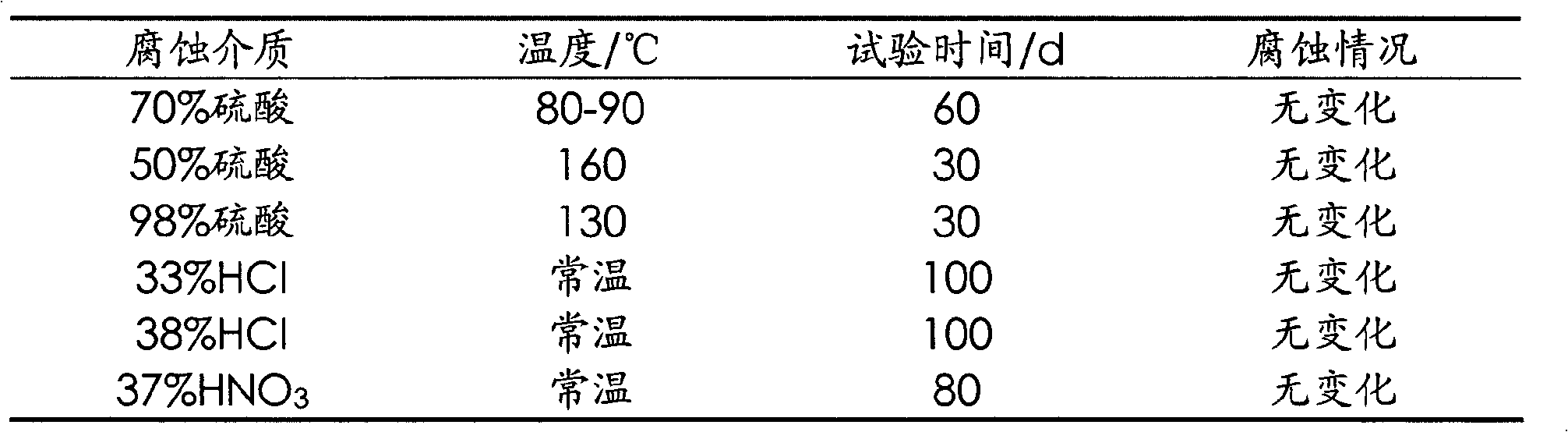

[0038] Mix 100 grams of vinylidene fluoride, hexafluoropropylene copolymer elastomer (molecular weight: 120,000) with 5 grams of carbon black and silica reinforcing agent, and dissolve in a mixture of 550 grams of acetone, butanone and ethyl acetate ( Volume ratio 1:2:1). Stir at room temperature for 2 hours, gradually add 10 g of curing catalyst bisphenol F dropwise, and continue stirring for 2 hours. Then sieve (200 mesh), adopt spraying method to coat, and cure at room temperature for 48 hours. According to the requirements of the national standard, it was sprayed into various samples for performance testing, and the results are shown in the table below:

[0039] Performance Testing

[0040]

Embodiment 2

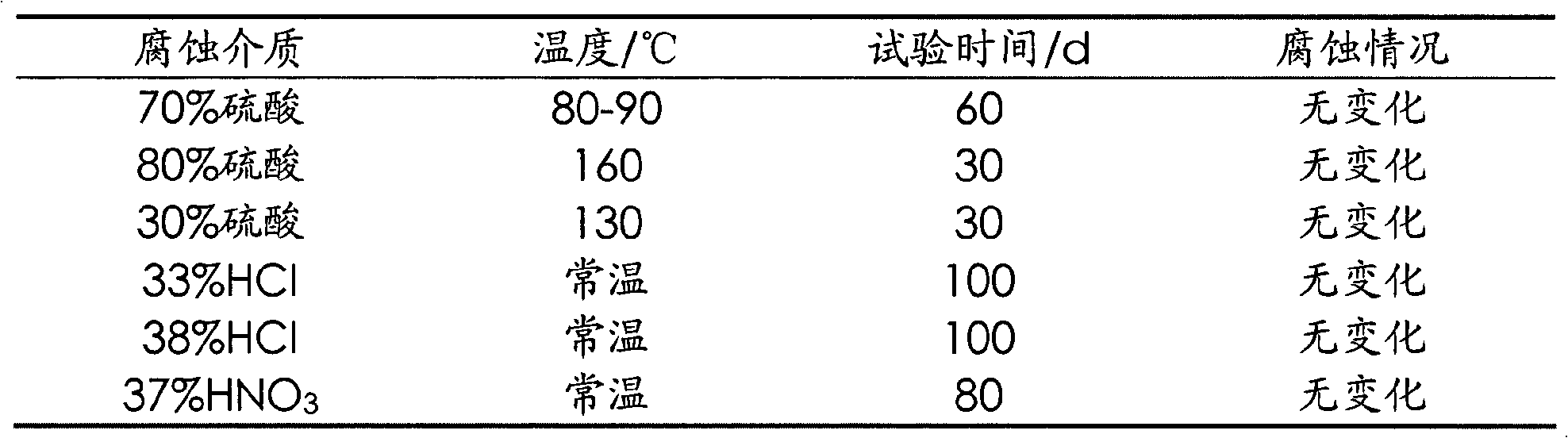

[0042] Mix 100 grams of vinylidene fluoride, hexafluoropropylene copolymer elastomer (molecular weight: 120,000) with 5 grams of carbon black and silica reinforcing agent, and dissolve in a mixture of 550 grams of acetone, butanone and ethyl acetate ( Volume ratio 1:2:1). Stir at room temperature for 2 hours, gradually add 10 g of curing catalyst bisphenol F dropwise, and continue stirring for 2 hours. Then it was sieved (200 mesh), painted by spraying method, and cured at 100°C for 4 hours. According to the requirements of the national standard, it was sprayed into various samples for performance testing, and the results are shown in the table below:

[0043] Performance Testing

[0044]

Embodiment 3

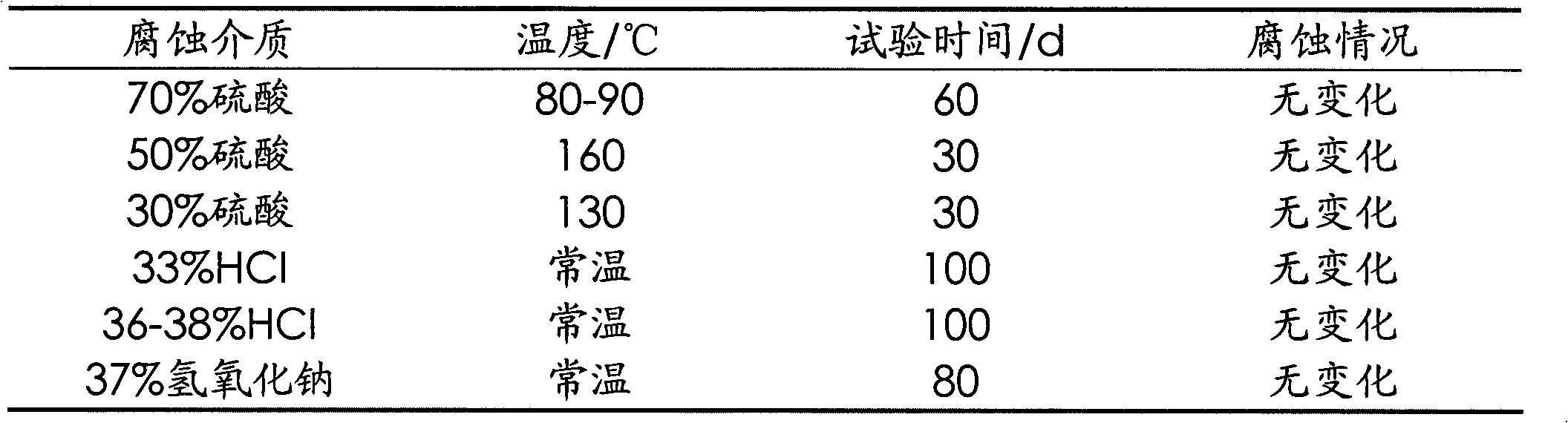

[0046] Mix 100 grams of vinylidene fluoride, hexafluoropropylene copolymer elastomer (molecular weight: 200,000) with 5 grams of carbon black and silica reinforcing agent, and dissolve in a mixture of 550 grams of acetone, butanone and ethyl acetate ( Volume ratio 1:2:1). Stir at room temperature for 2 hours, gradually add 10 g of curing catalyst bisphenol F dropwise, and continue stirring for 2 hours. Then sieve (200 mesh), adopt spraying method to coat, and cure at room temperature for 48 hours. According to the requirements of the national standard, it was sprayed into various samples for performance testing, and the results are shown in the table below:

[0047] Performance Testing

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com