Full hard hot dip galvanized steel plate with high strength and good surface quality and production method thereof

A technology of hot-dip galvanized steel sheet and surface quality, applied in the field of hot-dip galvanizing, it can solve the problems of temperature reduction, iron leakage or dezincification, and difficulty in ensuring the positive pressure of the furnace, so as to improve the strength and solve the problems of iron leakage and dezincification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The chemical composition (percentage by weight) of the steel is C: 0.15%, Mn: 1.00%, Si: 0.04%, Ti: 0.02%, and the balance is iron and unavoidable impurities.

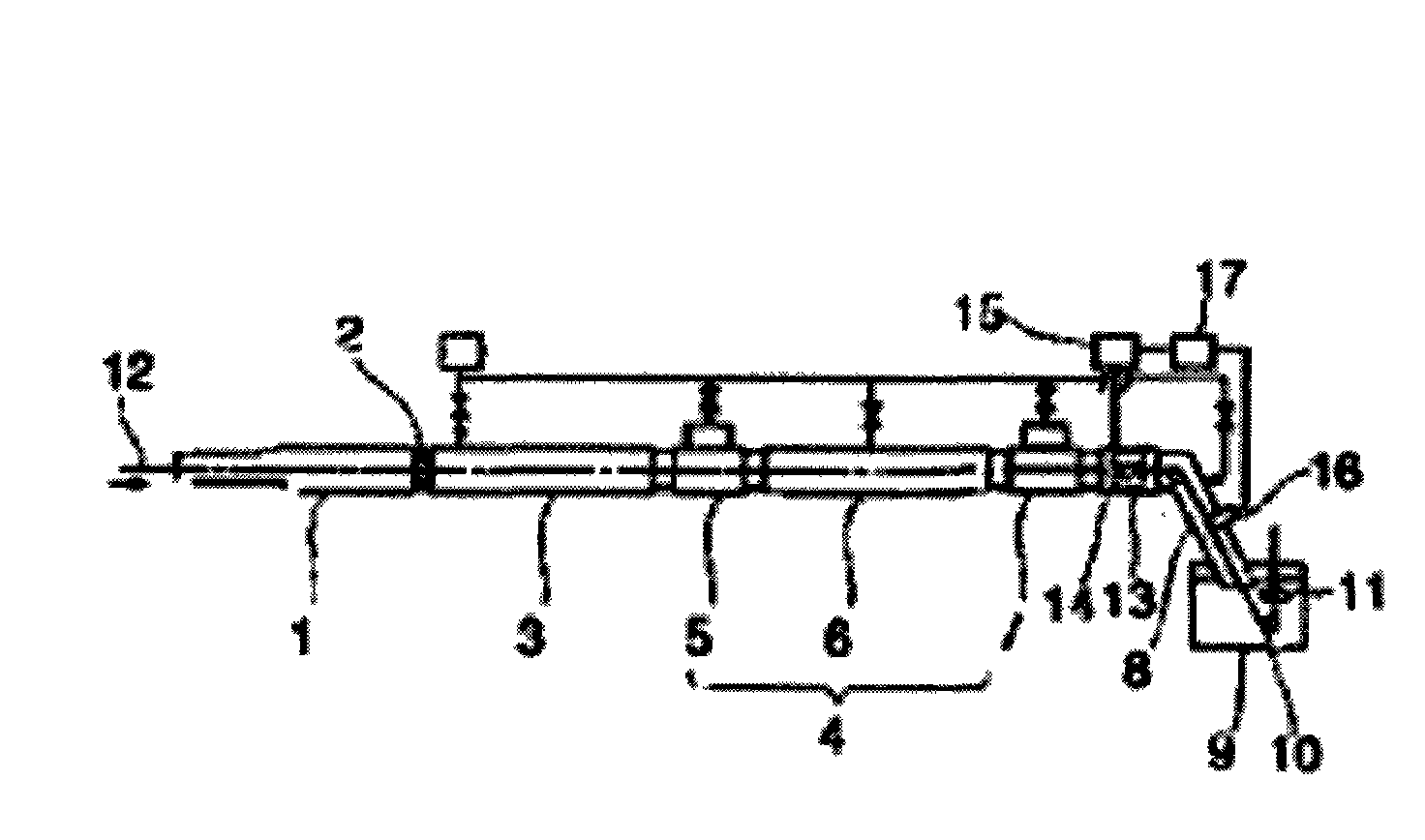

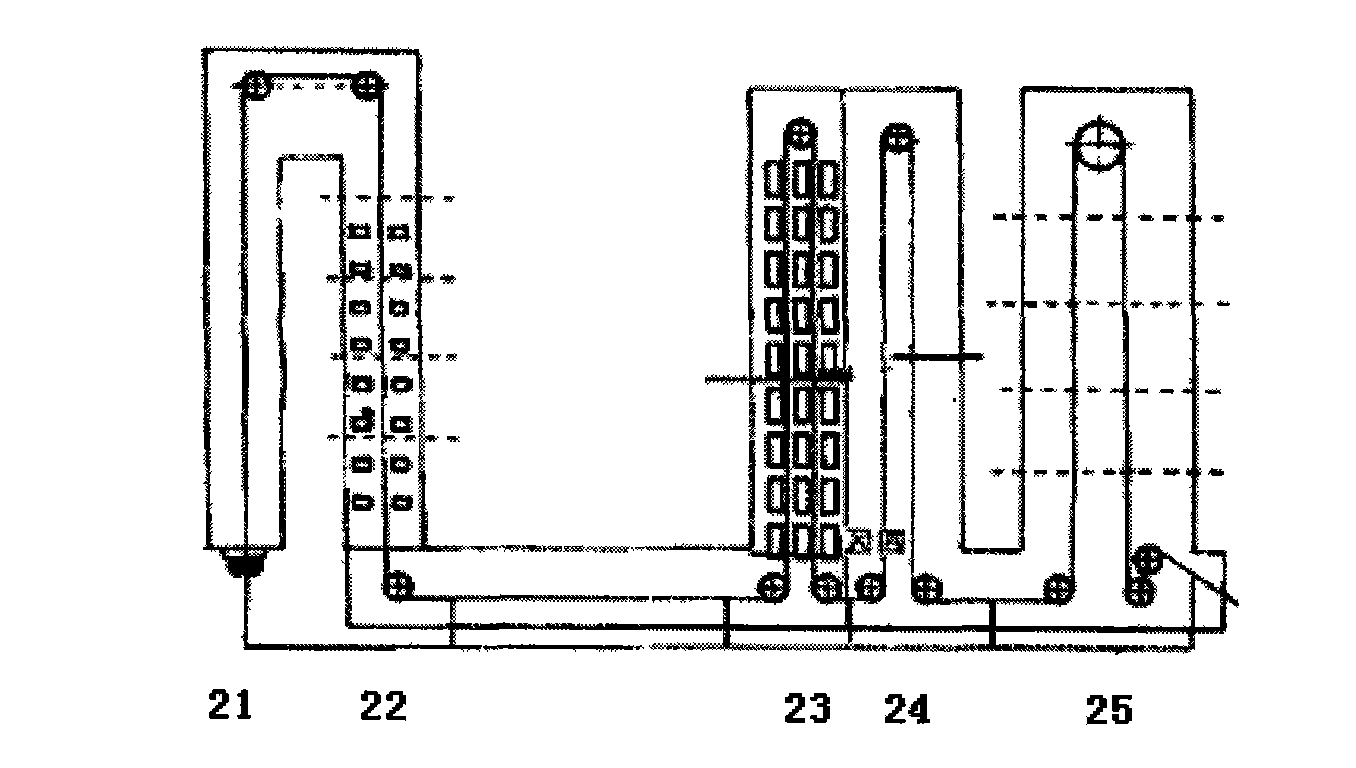

[0027] Its technological process is: converter smelting + refining outside the furnace → continuous casting → hot rolling → pickling and cold rolling → continuous hot dipping.

[0028]Use high-titanium ferro-titanium to control the titanium content in the steel; the heating temperature of hot rolling is 1200°C, the starting temperature of finishing rolling is 1000°C, the finishing rolling temperature is 860°C, the laminar flow cooling after rolling, and the coiling temperature is 550°C; the thickness specification of cold rolled sheet It is 0.6mm, and the cold rolling reduction rate is 70%. It is produced in the NOF vertical furnace continuous hot-dip galvanizing line, the continuous hot-dip annealing temperature is 600 ° C, and the heating gas fuel in the non-oxidation heating section is coke oven gas.

[0029]...

Embodiment 2

[0031] The chemical composition (percentage by weight) of the steel is C: 0.02%, Mn: 0.30%, Si: 0.05%, Ti: 0.08%, and the balance is iron and unavoidable impurities.

[0032] Its technological process is: converter smelting + refining outside the furnace → continuous casting and rolling → pickling and cold rolling → continuous hot dipping

[0033] Use ordinary ferro-titanium to control the titanium content in the steel; the heating temperature of hot rolling is 1260°C, the starting temperature of finish rolling is 1100°C, the finishing rolling temperature is 900°C, the cooling is rapid and concentrated after rolling, and the coiling temperature is 600°C; the thickness specification of cold-rolled plate is 0.4mm, cold rolling reduction rate of 80%; produced in NOF vertical furnace continuous hot-dip galvanizing line, continuous hot-dip plating annealing temperature 710 ° C, the heating gas fuel of the non-oxidation heating section is natural gas.

[0034] The surface quality of...

Embodiment 3

[0036] The chemical composition of steel (percentage by weight) C: 0.10%, Mn: 0.15% 0, Si: 0.03%, Nb: 0.04%, and the balance is iron and unavoidable impurities.

[0037] Its technological process is: converter smelting + refining outside the furnace → continuous casting and rolling → pickling and cold rolling → continuous hot dipping

[0038] The heating temperature of hot rolling is 1150°C, the start rolling temperature of finish rolling is 1050°C, the finishing rolling temperature is 850°C, rapid concentrated cooling after rolling, and the coiling temperature is 650°C; the thickness of cold rolled plate is 0.8mm, and the reduction rate of cold rolling is 60%; It is produced in the NOF vertical furnace continuous hot-dip galvanizing line, the continuous hot-dip galvanizing temperature is 690°C, and the heating gas fuel in the non-oxidation heating section is coke oven gas.

[0039] The surface quality of the obtained galvanized steel strip meets the surface requirements of FB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com