Hollow anode ion source used for ultra high vacuum system

An anode ion source and ultra-high vacuum technology, applied in ion beam tubes, ion implantation plating, vacuum evaporation plating, etc., can solve the problems of increased film roughness, undisclosed electrical insulation, and inability to propose based on it. To achieve the effect of compact structure, small volume and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

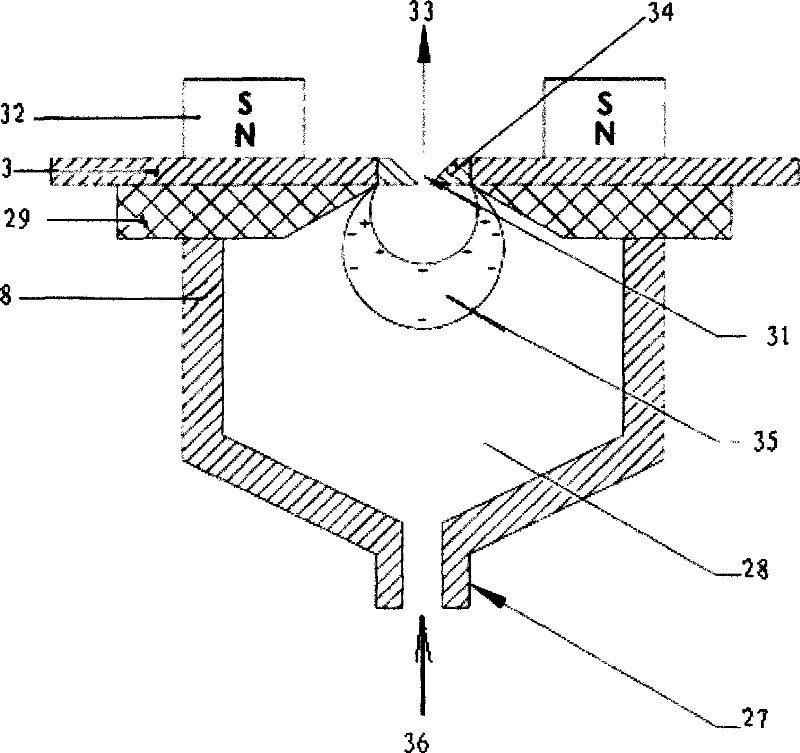

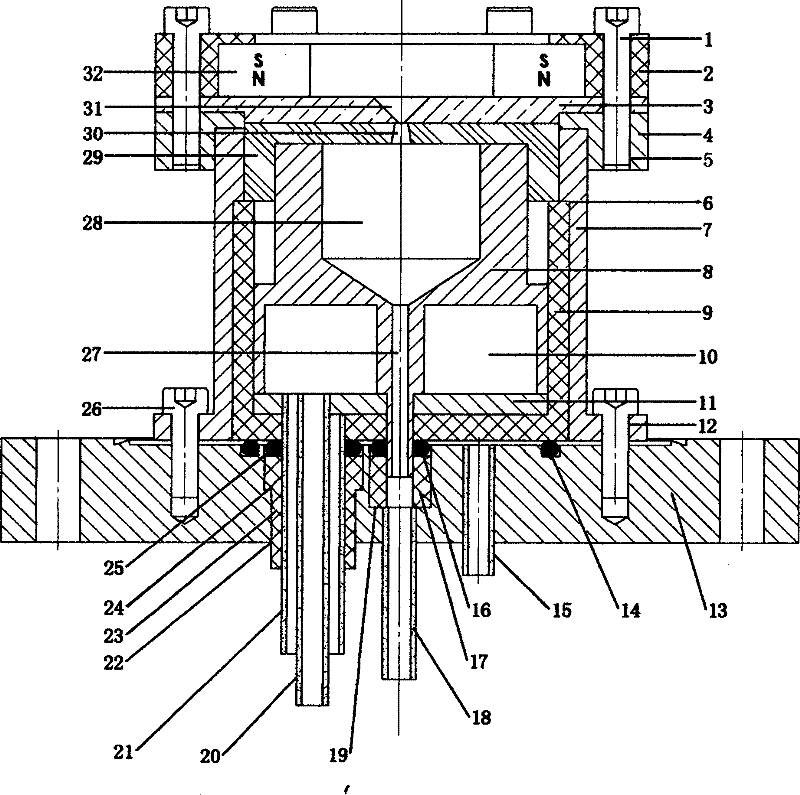

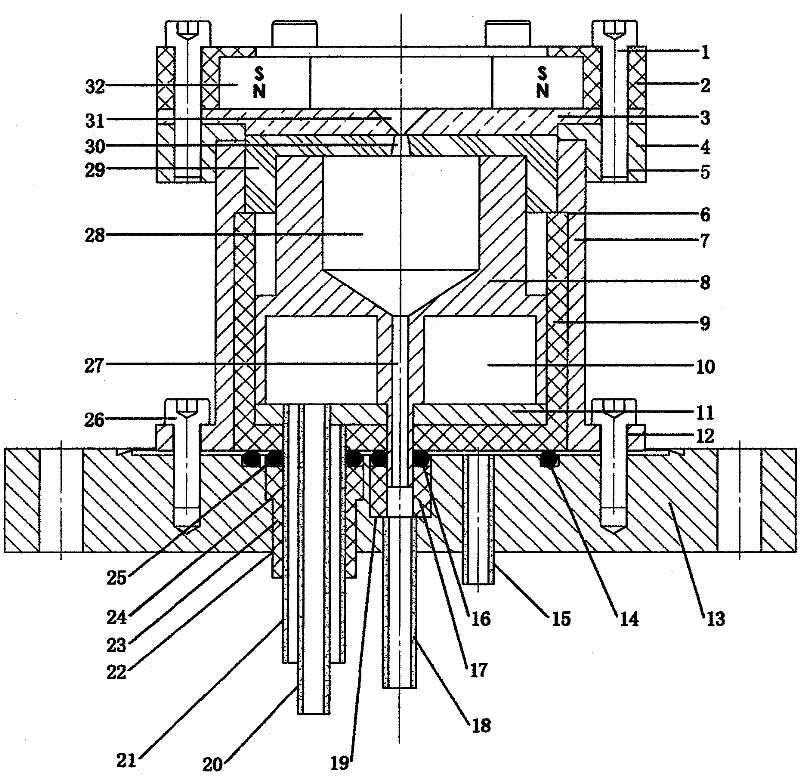

[0016] see figure 1 and figure 2 , the hollow anode ion source used in the ultra-high vacuum system includes the cathode 8 coaxially connected in series on the flange 13, the anode 3 with the central nozzle 31 and the permanent magnet 32 of the outer magnet cover 2. Its specific structure is as follows:

[0017] The lower part of the cathode 8 is a water-cooled cavity 10, and the upper part is a hollow ionization chamber 28, and an insulating sleeve and a metal sleeve are sequentially set outside it; wherein, the insulating sleeve is a butt-connected insulating bottom sleeve 9 and a vent hole 30 in the center. The insulating top sleeve 29, the metal sleeve is the upper metal sleeve 4 and the lower metal sleeve 7 connected by welding, and the inner wall of the lower metal sleeve 7 is provided with a shoulder 6 which interferes with the upper surface of the insulating bottom sleeve 9. The surface of the chemical chamber 28 is covered with a titanium nitride coating (or tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com