Corrosion-resistant alkali pan and manufacturing process thereof

A technology for corrosion-resistant alkaline pots, applied in chemical/physical/physicochemical processes, evaporation, chemical instruments and methods, etc., which can solve problems such as increased energy consumption, small capacity of corrosion-resistant alkaline pots, and poor heat transfer , to achieve the effect of improving service life, strong corrosion resistance, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

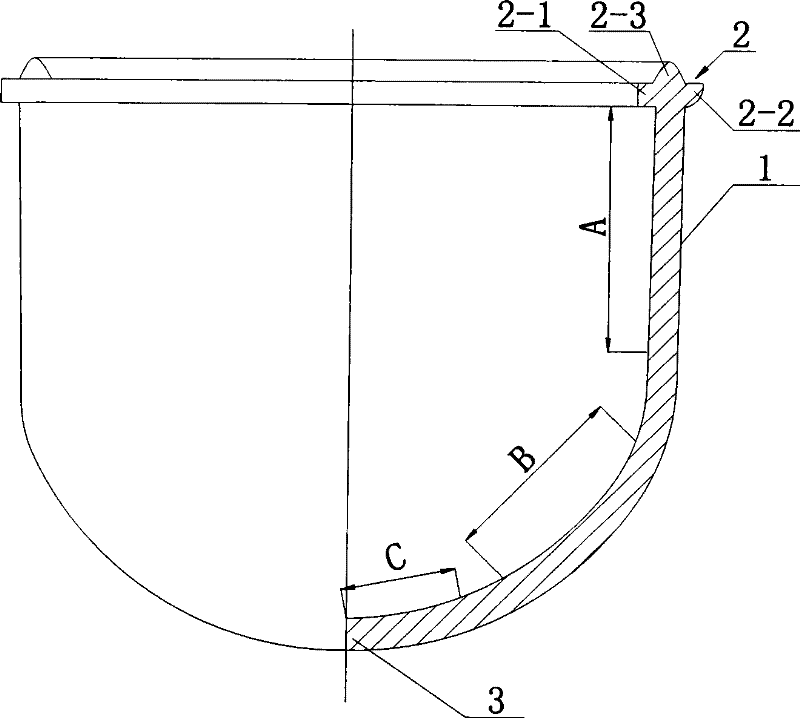

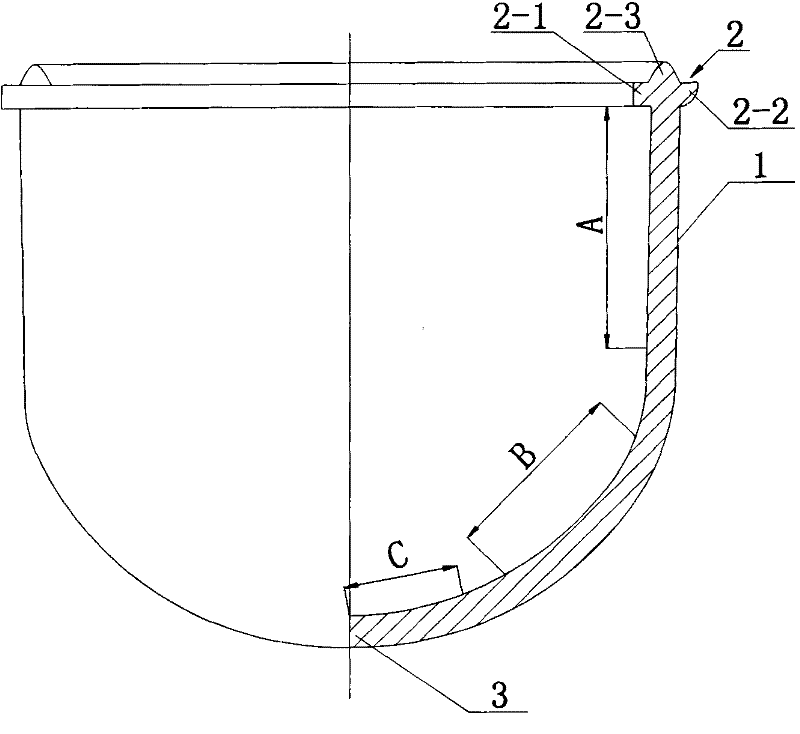

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0024] see figure 1 , the inner edge 2-1 and the outer edge 2-2 are formed on the same plane at the 2 parts of the pot mouth, the inner edge 2-1 effectively prevents the liquid from splashing when the liquid in the pot boils, and the outer edge 2-2 facilitates It is positioned and installed with the pot platform; the upper surface of the inner edge 2-1 and the outer edge 2-2 is shaped with a boss 2-3, so as to cooperate with the positioning of the pot cover and play a positioning role, in order to prevent the sealing of the pot cover , the cross section of the boss 2-3 is made into a triangle, and its adjacent two sides are arc-shaped, and the adjacent two sides are connected by an arc; the wall thickness of the pot body 1 from the pot mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com