Polymerizing-pyrolytic method for preparing mesocarbon microbead in asphaltic base

A mesophase carbon microsphere and pitch-based technology, which is applied in the field of carbon materials, can solve the problems of low yield, uneven shape and size, and low preparation cost of mesophase carbon microspheres, and achieve easy operation, wide application, and particle size The effect of uniform diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

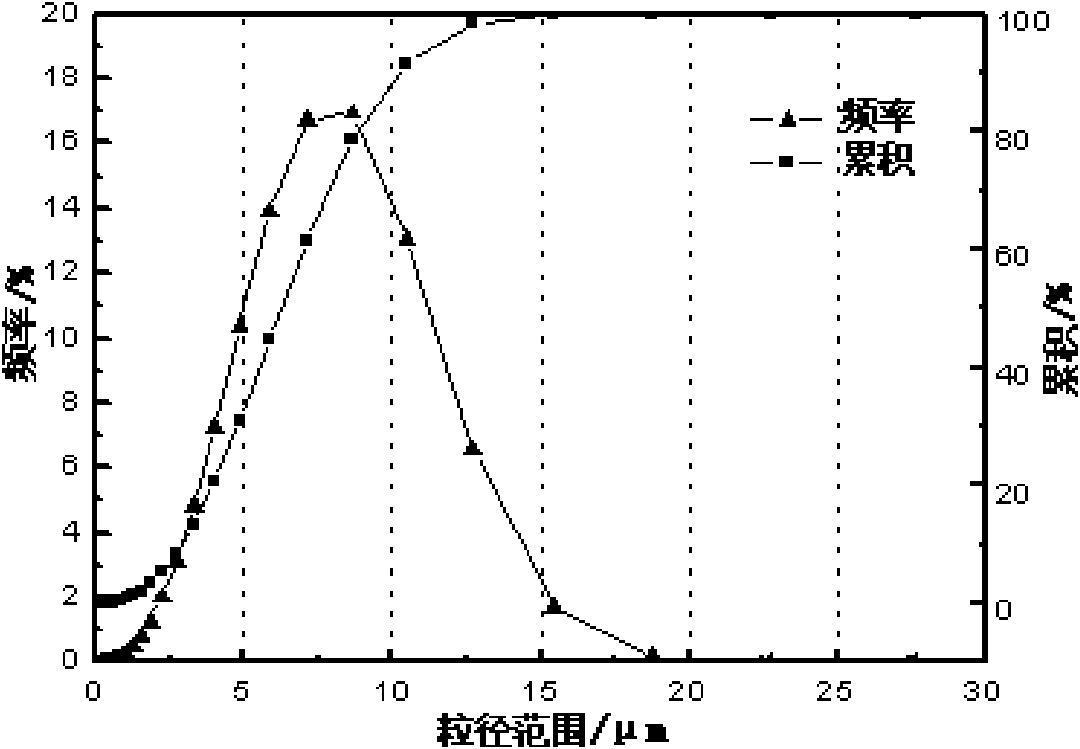

[0039] Coal tar pitch is used as raw material, formaldehyde is used as cross-linking agent, oxalic acid is used as catalyst, and the mass ratio of the three is 100:4:2. Add it into a three-necked flask. Before 100°C, the temperature is raised freely, and after 100°C, the speed is 5°C / min. The temperature is raised, and N is introduced from the beginning of the temperature rise 2 , N 2 The flow rate was 50mL / min, and the reaction was carried out at 130°C for 2h, and the obtained polymerized modified bitumen was 2 Treated at 420°C for 2 hours under protection, then dissolved by pyridine (the mass ratio of pyridine to pyrolysis product is 60:1) and extracted until colorless, and dried in vacuum to obtain mesophase carbon microspheres with a particle size of about 8 μm. The yield is 30.74%. Good sphericity and narrow particle size distribution.

Embodiment 2

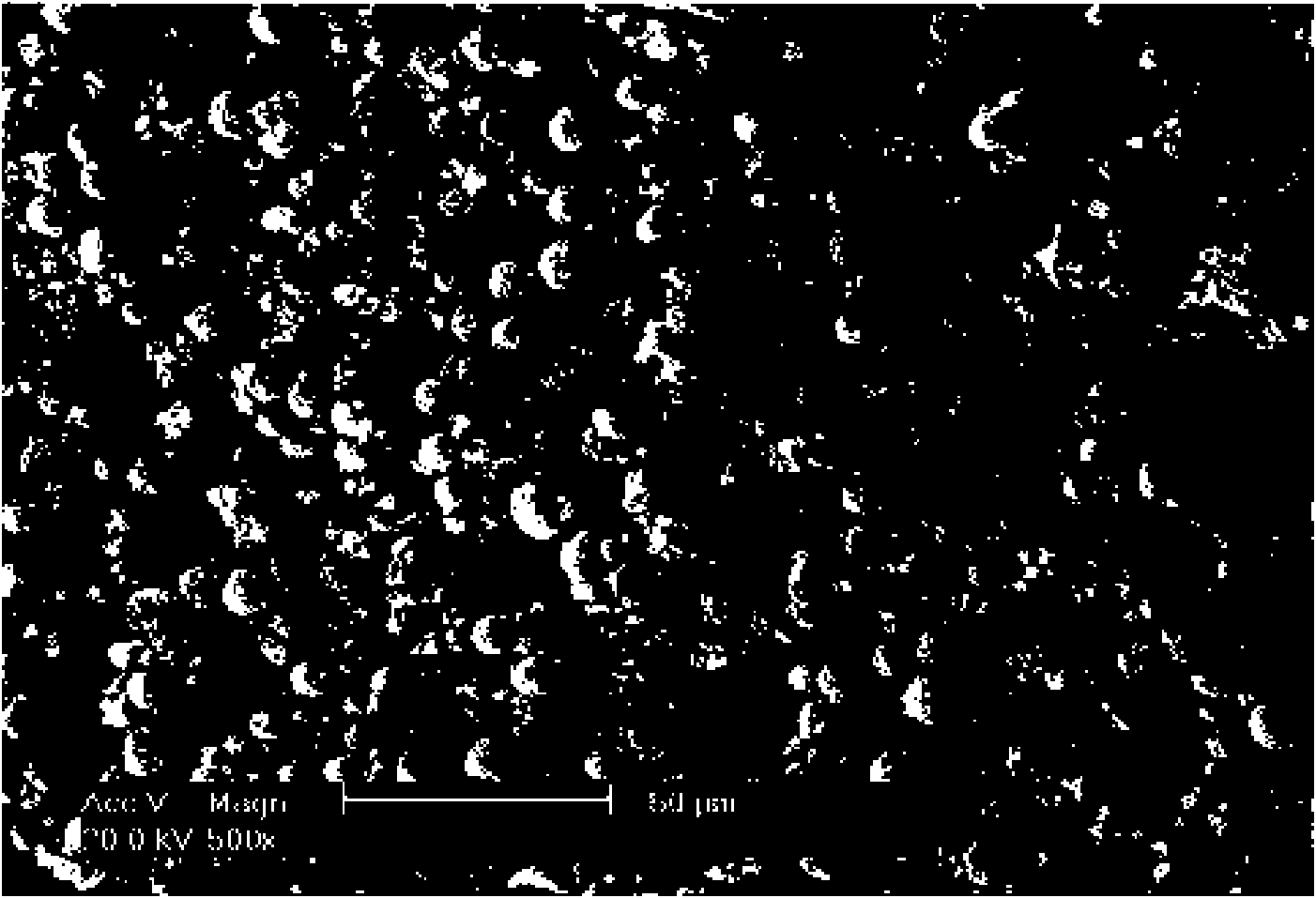

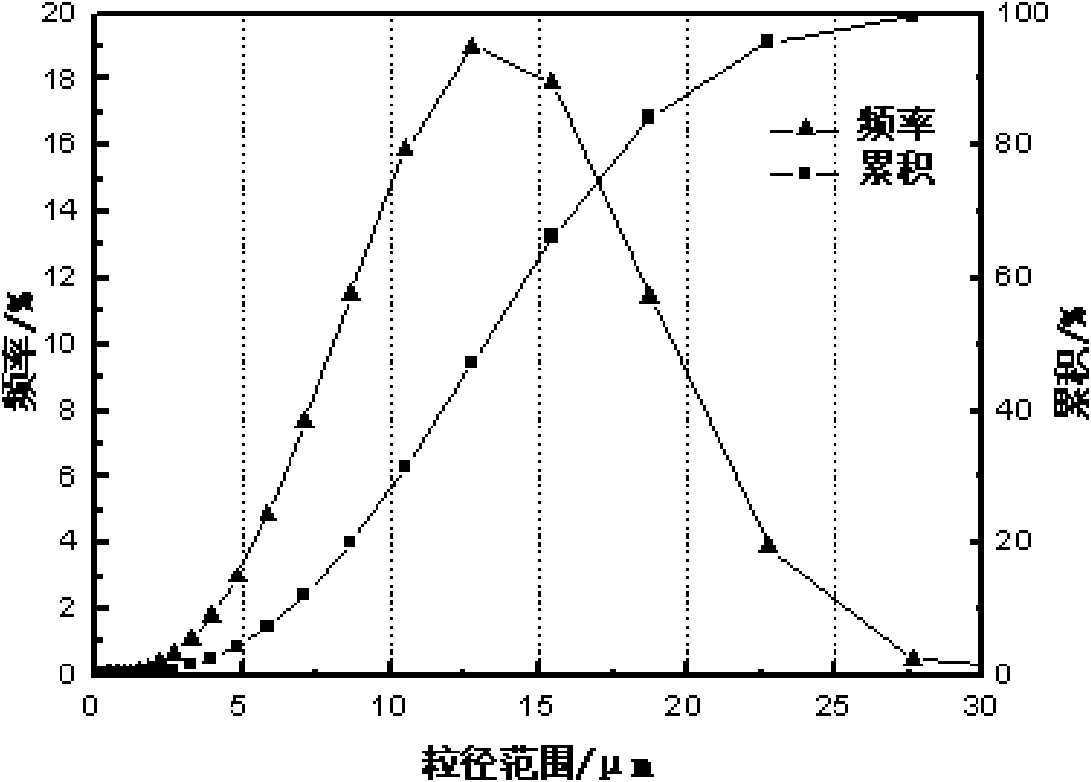

[0041] Coal tar pitch is used as raw material, benzaldehyde is used as cross-linking agent, and p-toluenesulfonic acid is used as catalyst, and the mass ratio of the three is 100:12:2. / min rate of heating, and from the beginning of heating N into 2 , N 2 The flow rate was 50mL / min, and the reaction was carried out at 130°C for 3h, and the obtained polymerized modified bitumen was 2 Treat at 460°C for 2 hours under protection, then extract to colorless with pyridine (the mass ratio of pyridine to pyrolysis product is 60:1), and dry in vacuum to obtain mesophase carbon microspheres with a particle size of about 12 μm. The rate is 40.62%. The sphericity is good, and the fusion between carbon microspheres rarely occurs.

Embodiment 3

[0043] Coal tar pitch is used as raw material, p-tolualdehyde is used as cross-linking agent, oxalic acid is used as catalyst, and the mass ratio of the three is 100:8:2. / min rate of heating, and from the beginning of heating N into 2 , N 2 The flow rate was 50mL / min, and the reaction was carried out at 140°C for 2h, and the obtained polymerized modified bitumen was 2 Treat at 450°C for 1 h under protection, then extract to colorless with pyridine (the mass ratio of pyridine to pyrolysis product is 60:1), and dry in vacuum to obtain mesophase carbon microspheres with a particle size of about 10 μm. The rate is 35.54%. Good sphericity, good surface finish, and little fusion between balls.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com