Double-component addition self-adhesive silicon rubber

An addition-type, silicone rubber technology, applied in the field of silicone rubber, can solve problems such as high hardness, unsatisfactory, and non-self-adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

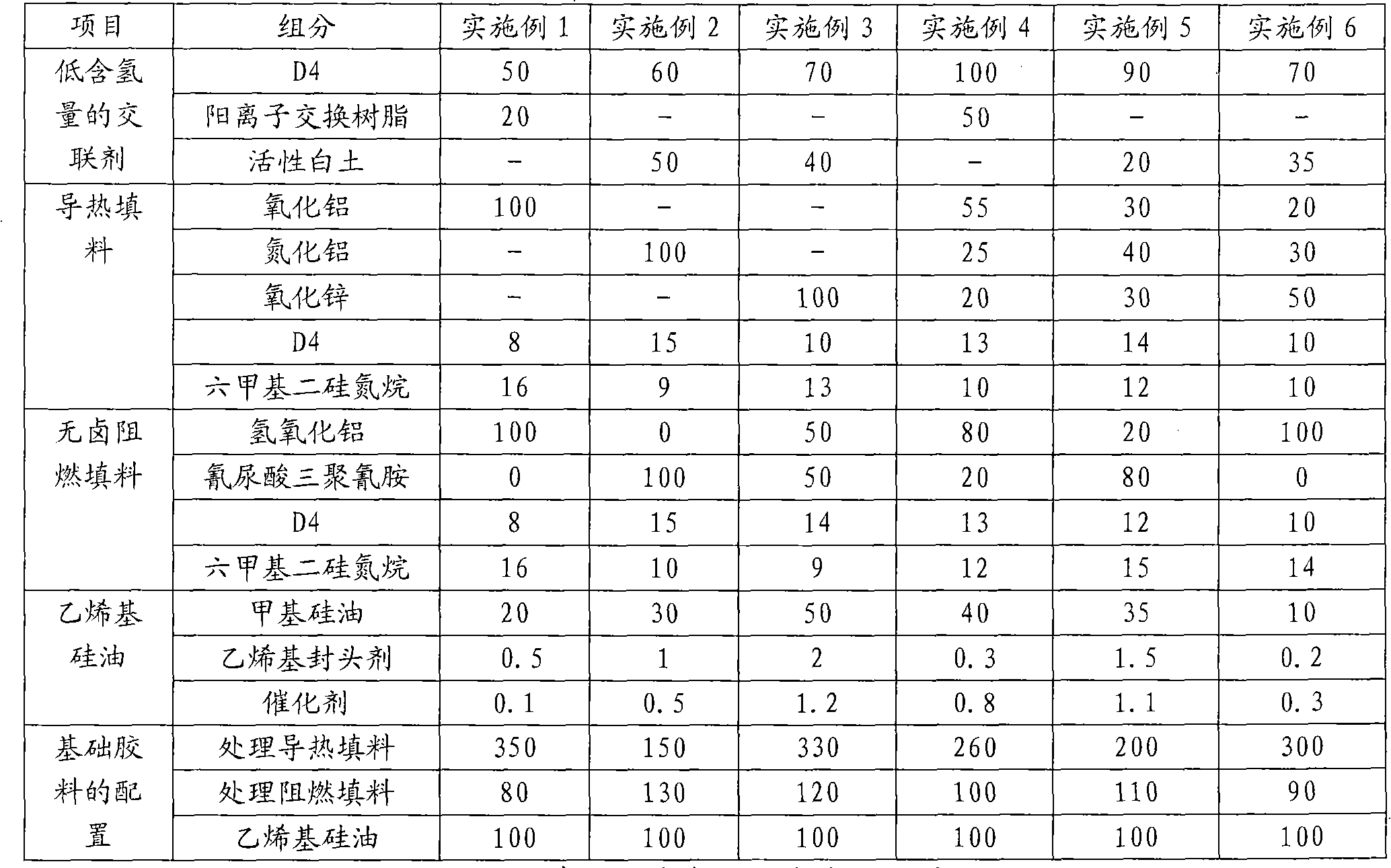

[0047] The cross-linking agent with low hydrogen content described in material A is prepared by the following method:

[0048] Add 100 parts of hydrogen-containing silicone oil and 50 to 100 parts of D4 into the reactor, add 20 to 50 parts of activated clay or cation exchange resin as a catalyst, stir, and react at a temperature of 85°C to 120°C for 6 to 10 hours. Stop stirring, cool to room temperature, and filter, and the obtained filtrate is a cross-linking agent with low hydrogen content.

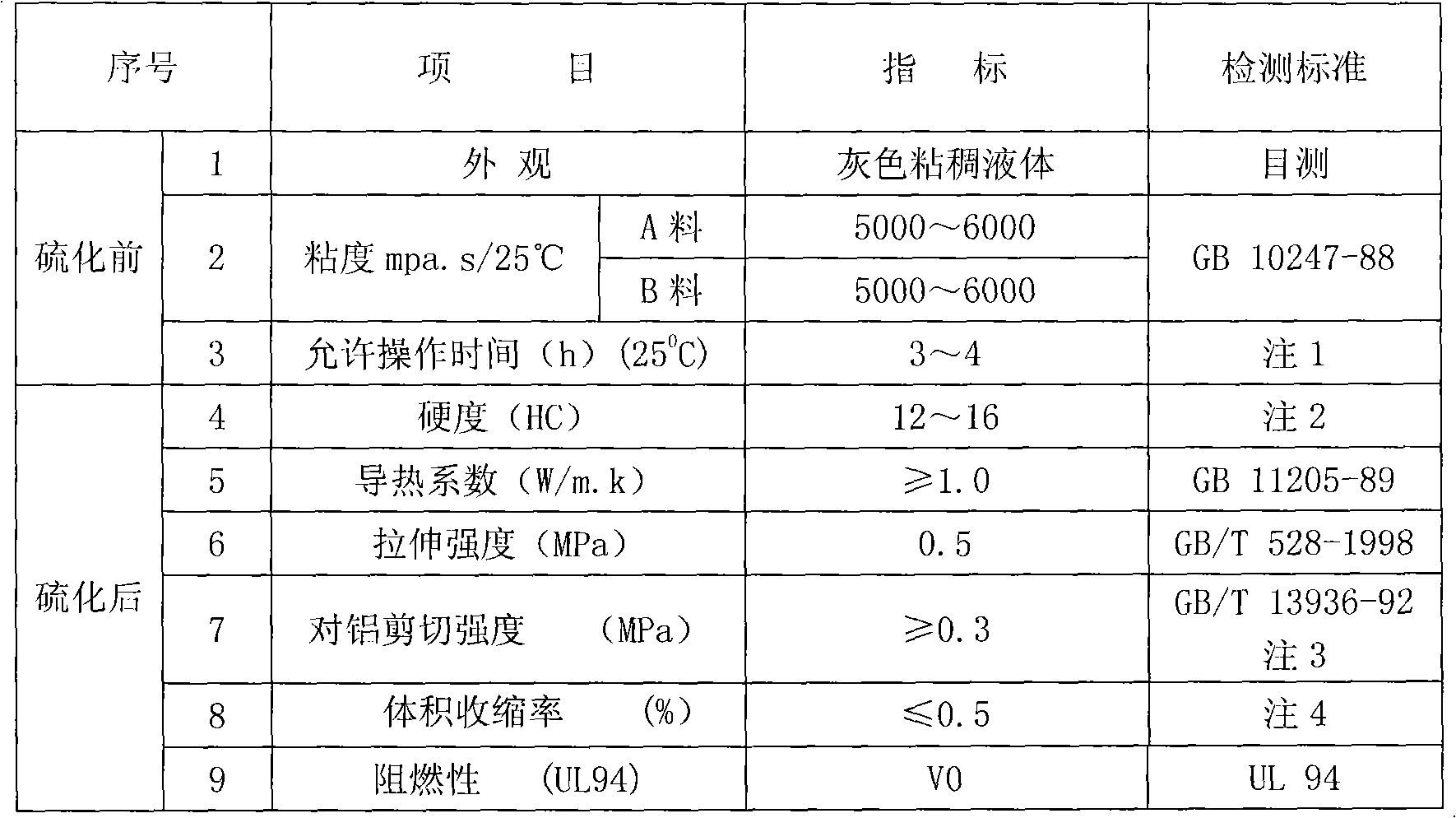

[0049] The base rubber in materials A and B is prepared from 100 parts of vinyl silicone oil, 80-130 parts of halogen-free flame-retardant fillers, and 150-350 parts of thermally conductive fillers. The halogen-free flame-retardant fillers are aluminum hydroxide or / and melamine cyanurate, the thermally conductive filler is any one or more of aluminum oxide, aluminum nitride, and zinc oxide.

[0050] The preparation method of base glue comprises the following steps:

[0051] (1), pro...

Embodiment 1

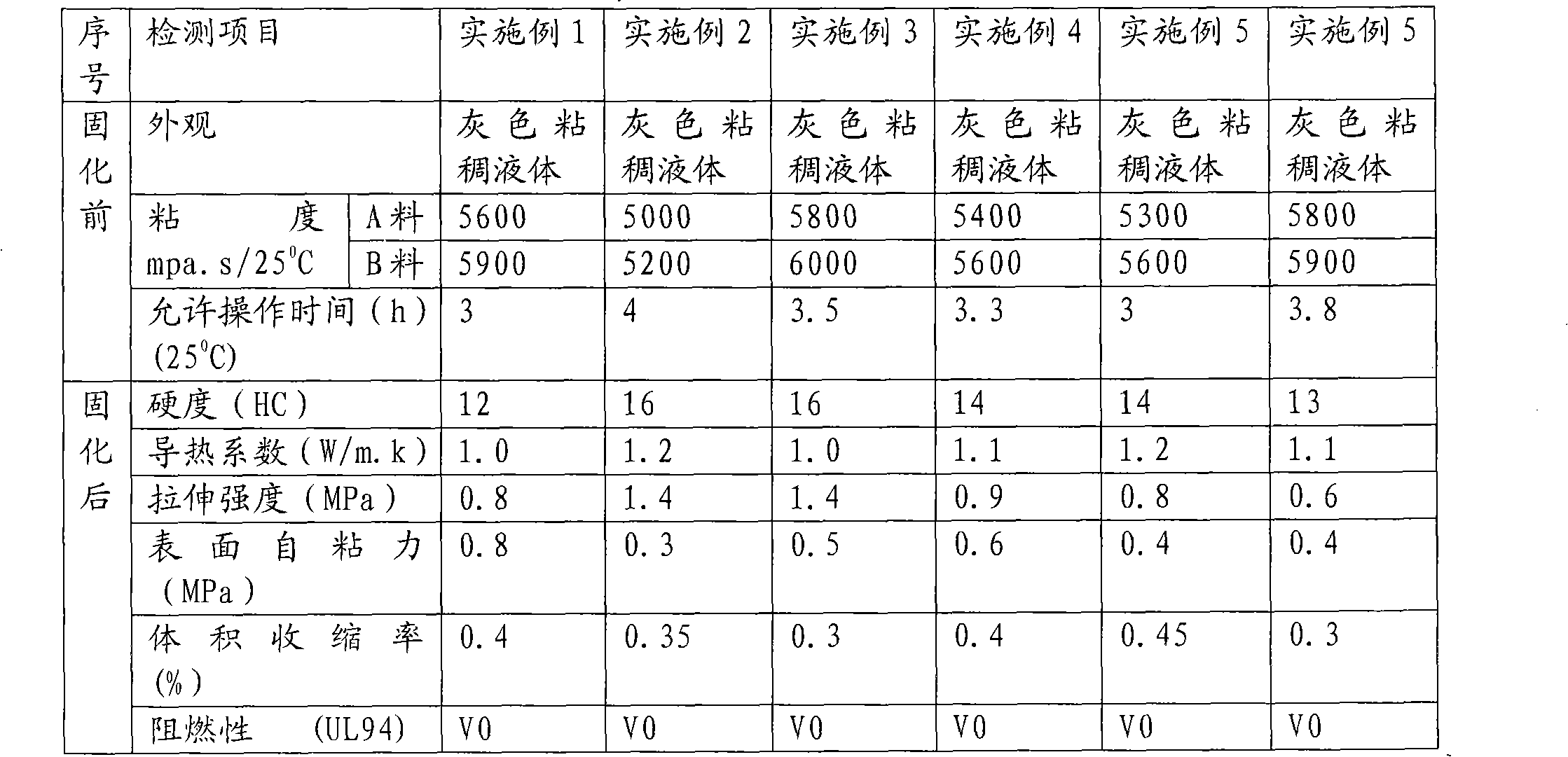

[0059] Material A of the two-component addition type self-adhesive silicone rubber in this embodiment is made by mixing 100 parts of base rubber and 2 parts of crosslinking agent with low hydrogen content; material B is made of 100 parts of base rubber, chloroplatinic acid complex 0.18 parts mixed.

[0060] See Table 2 for the raw material proportions of the crosslinking agent with low hydrogen content and the base rubber. The preparation method of the cross-linking agent with low hydrogen content and the base rubber is the same as that described in the embodiment, wherein the reaction temperature used to prepare the cross-linking agent is 85° C., and the reaction time is 10 h. When preparing vinyl silicone oil, heat up to 180°C after the initial polymerization of the raw materials, maintain for 30 minutes, and then remove the low molecular weight; when preparing the base rubber, heat up to 150°C to 160°C under stirring after the first feeding, and maintain under stirring Aft...

Embodiment 2

[0067] Material A of the two-component addition type self-adhesive silicone rubber of this embodiment is made by mixing 100 parts of base rubber and 2.8 parts of crosslinking agent with low hydrogen content; material B is made of 100 parts of base rubber and chloroplatinic acid complex 0.12 parts and 1 part color masterbatch are mixed.

[0068] See Table 2 for the raw material proportions of the crosslinking agent with low hydrogen content and the base rubber. The preparation method of the cross-linking agent with low hydrogen content and the base rubber is the same as that described in the embodiment, wherein the reaction temperature for preparing the cross-linking agent is 120° C., and the reaction time is 8 hours. When preparing vinyl silicone oil, heat up to 150°C after the initial polymerization of the raw materials, maintain for 120 minutes, and then remove the low molecular weight; when preparing the base rubber, heat up to 170°C to 180°C under stirring after the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com