Copper-base powder metallurgy clutch friction body

A powder metallurgy, clutch technology, applied in the direction of friction lining, mechanical equipment, etc., can solve the problems of shear resistance, low compressive strength, large wear, uneconomical, etc., and achieve good thermal stability, stable friction coefficient, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

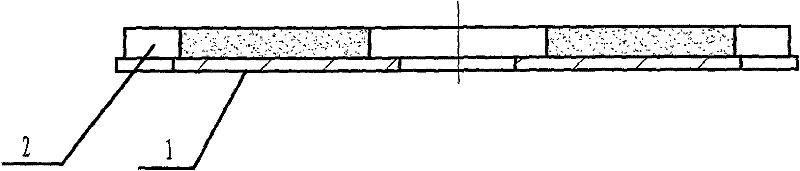

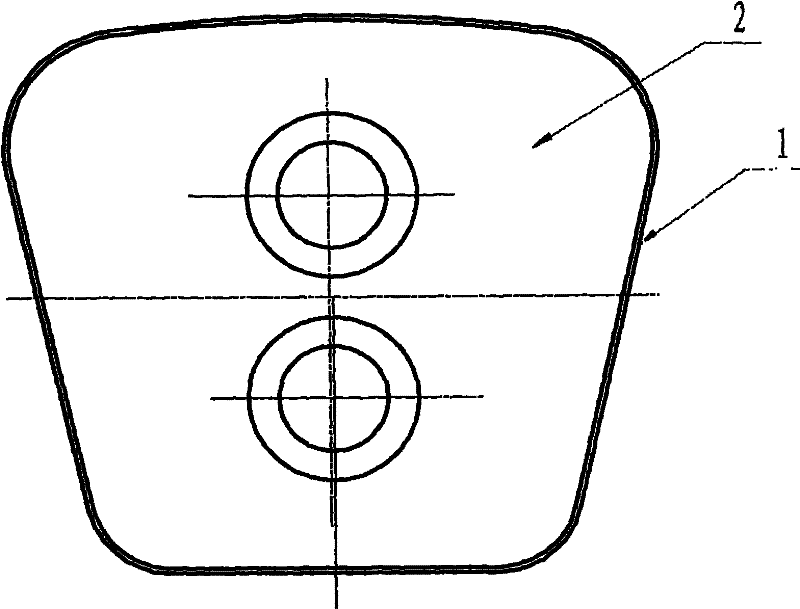

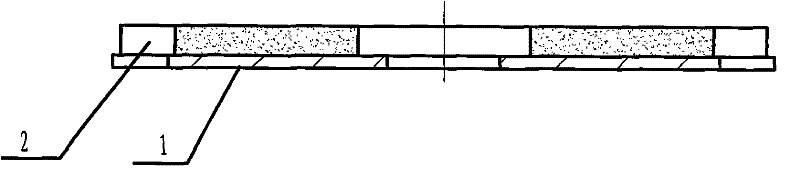

[0034] Embodiment 1: The first copper-based powder metallurgy clutch friction body, see figure 1 with figure 2 A piece of copper-based powder metallurgy friction plate 2 is stacked on the steel core plate 1, and sintered into one under pressure; the composition and specifications of the copper-based powder metallurgy friction plate 2 are shown in Table 1

[0035] Table 1

[0036]

[0037]Note: ※ is a batch of graphite powder, and its batch ratio is: -60~+100 mesh accounts for 75%; -100~+140 mesh accounts for 15%; -200 mesh accounts for 10%; Cu·Fe is copper clad iron composite Powder, its patent number is: ZL031178634, executive standard: Q / CYZ.6-2001.

[0038] The manufacturing process of the first copper-based powder metallurgy clutch friction body is as follows:

[0039] The first step is to prepare materials according to the above formula → batching → mixing → pressing to obtain copper-based powder metallurgy friction plate 2; the pressing process is carried out on Y...

Embodiment 2

[0047] Embodiment 2: The second copper-based powder metallurgy clutch friction body, see figure 1 with figure 2 A piece of copper-based powder metallurgy friction plate 2 is stacked on the steel core plate 1, and sintered into one under pressure; the composition and specifications of the copper-based powder metallurgy friction plate 2 are shown in Table 2.

[0048] Table 2

[0049]

[0050] Note: ※ is a batch of graphite powder, and its batch ratio is: -60~+100 mesh accounts for 75%; -100~+140 mesh accounts for 15%; -200 mesh accounts for 10%; Cu·Fe is copper clad iron composite Powder, its patent number is: ZL031178634, executive standard: Q / CYZ.6-2001.

[0051] The manufacturing process of the second copper-based powder metallurgy clutch friction body is as follows:

[0052] The first step is to prepare materials according to the above formula → batching → mixing → pressing to obtain copper-based powder metallurgy friction plate 2. The pressing process is carried out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com