Column-shaped microbial fuel cell without ion exchange membrane or mediator

An ion exchange membrane and fuel cell technology, applied in the field of microbial fuel cells, can solve the problems of increased cost, electron transfer, and large proportion of electric energy consumption, and achieve the effects of reducing construction costs, reducing losses, and speeding up the reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

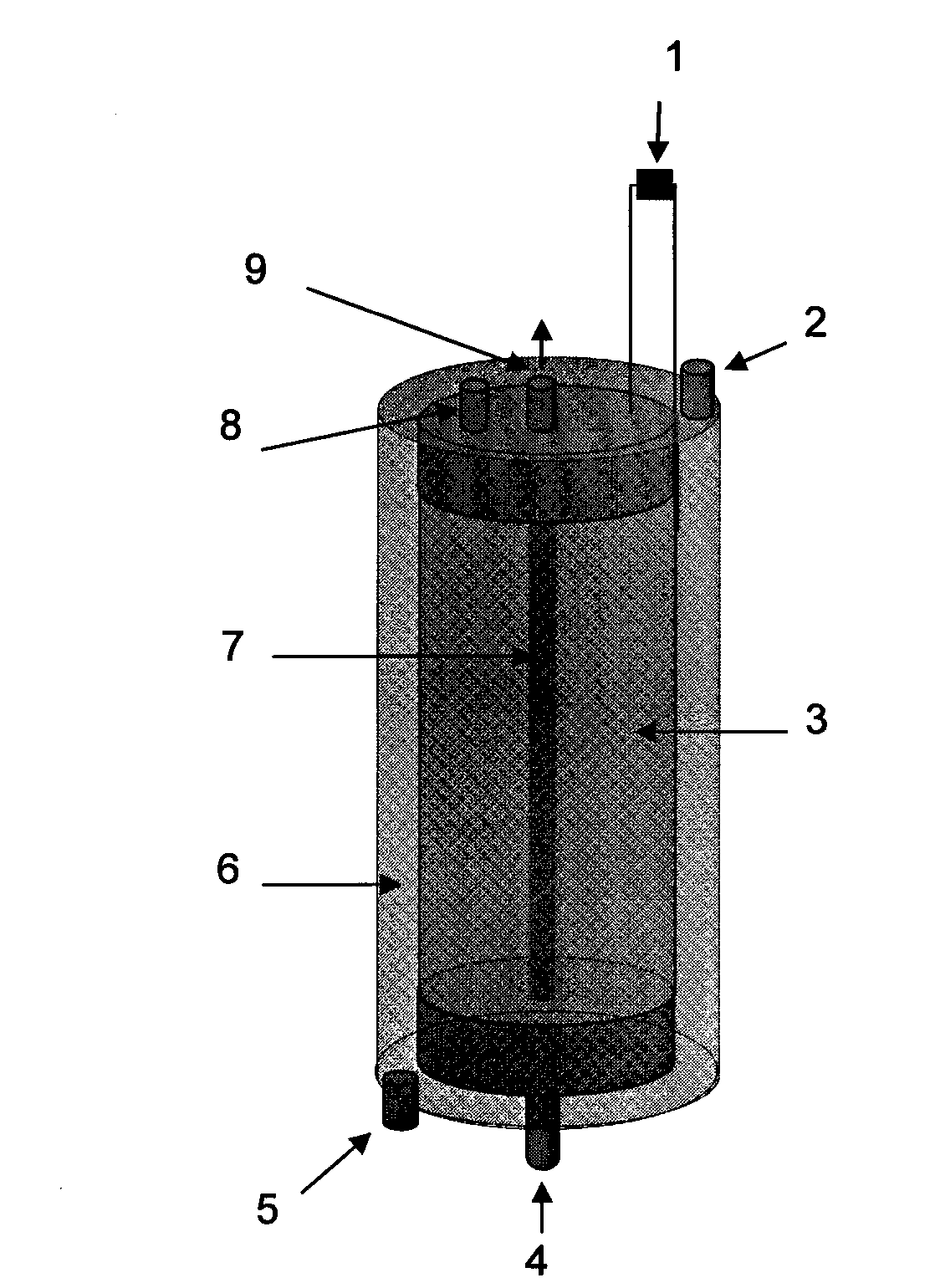

Embodiment 1

[0022] 1) Use plexiglass material to make the inner cylinder and outer cylinder of the microbial fuel cell;

[0023] 2) Determine that the effective volume of the cathode and anode reaction chambers is 200-300ml;

[0024] 3) The thickness of the cylindrical cylinder wall is 1-3cm. Under the premise of ensuring sufficient structural strength, the cylindrical cylinder wall should be drilled and hollowed out as much as possible;

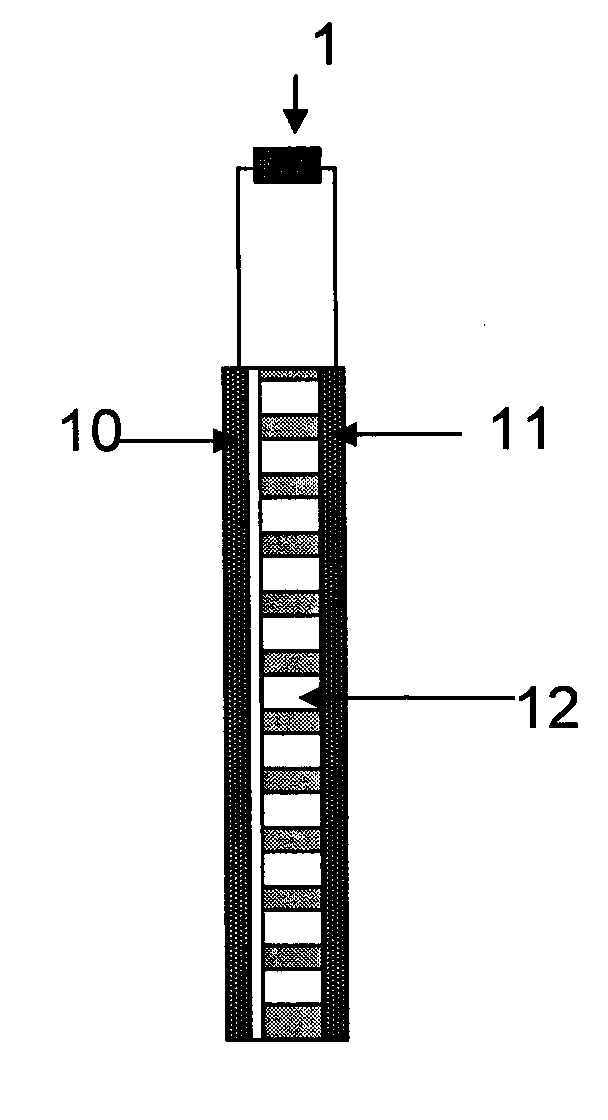

[0025] 4) Anode carbon cloth and cathode carbon cloth are attached to the inside and outside of the anode chamber wall respectively;

[0026] 5) Fill the anode chamber with granular activated carbon, and connect the activated carbon with the external circuit with a carbon rod;

[0027] 6) Inject the organic pollutants in the organic wastewater into the anode chamber as electron donors, domesticate the microorganisms in the wastewater as electrogenic bacteria, and use nitrate as the electron acceptor.

[0028] The principle of the microbial fuel cell i...

Embodiment 2

[0030] 1) Use plexiglass materials to make microbial fuel cells;

[0031] 2) Determine the effective volume of the cathode and anode reaction chambers to be 30-50ml;

[0032] 3) The thickness of the cylindrical cylinder wall is 0.5-1cm. Under the premise of ensuring sufficient structural strength, the cylindrical cylinder wall should be drilled and hollowed out as much as possible;

[0033] 4) Anode carbon cloth and cathode carbon cloth are attached to the inside and outside of the anode chamber wall respectively;

[0034] 5) Fill the anode chamber with granular activated carbon, and connect the activated carbon with the external circuit with a carbon rod;

[0035] 6) Inject glucose as electron donor into the anode chamber, and ferricyanide as electron acceptor.

[0036] The design principle of the microbial fuel cell in this embodiment is to meet the miniaturization requirements of the microbial incoming battery and increase the battery potential by reducing the structural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com