Membrane integrated microtrip ferrite circulator

A technology of ferrite and circulators, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of small effective permeability tensor k/μ, unfavorable microwave circuit integration, etc., to reduce volume and facilitate Integrate and promote the effect of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

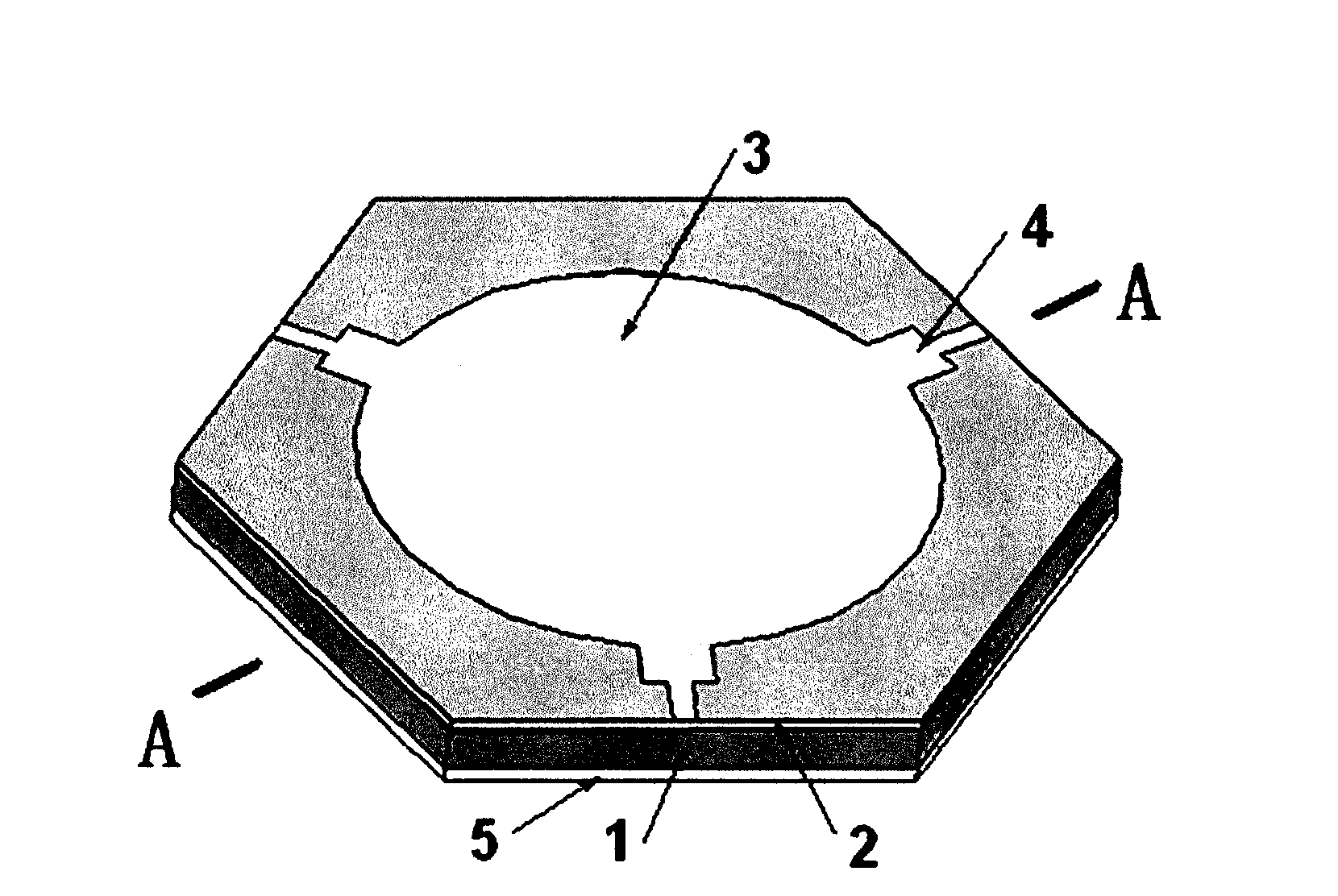

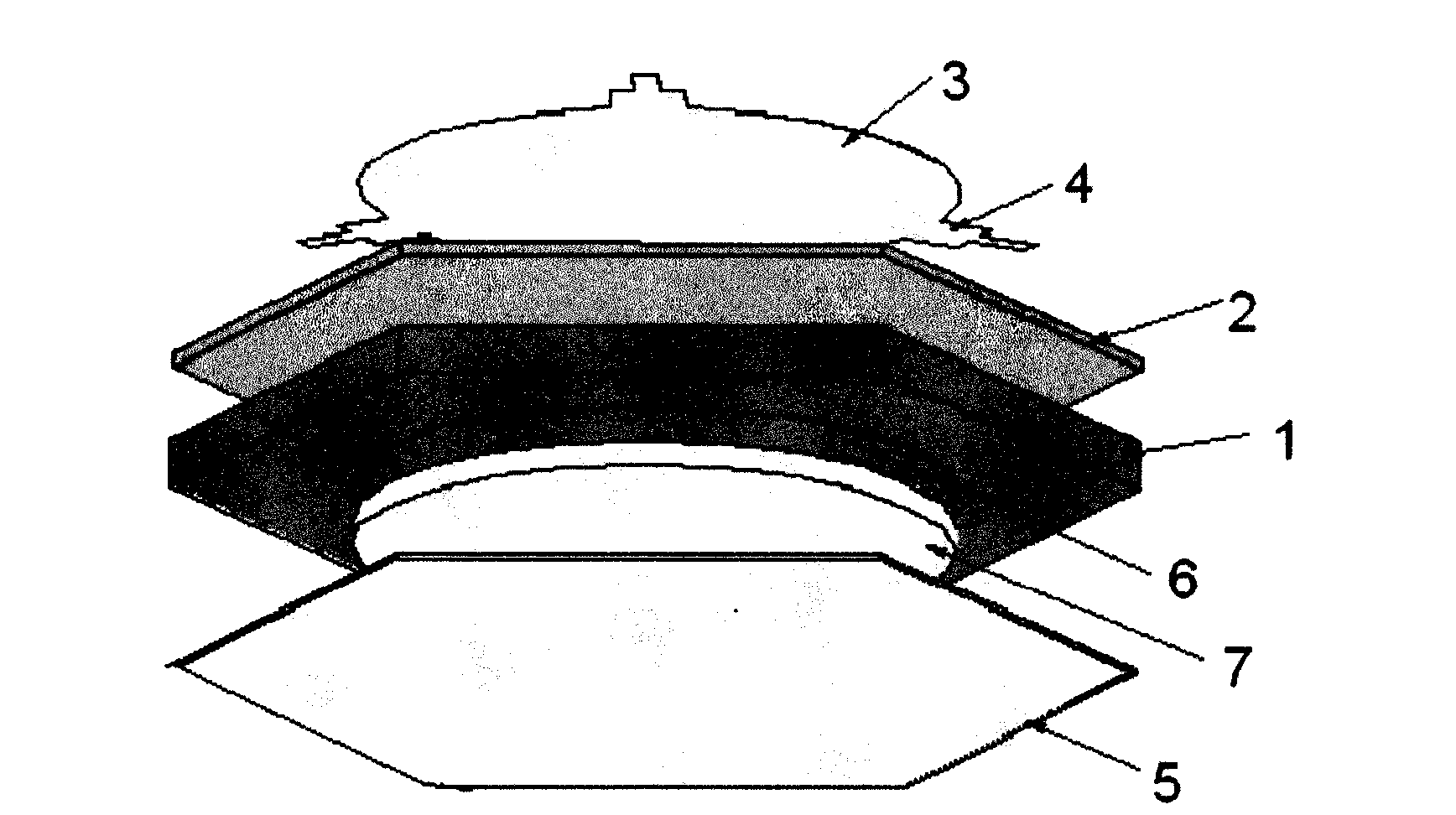

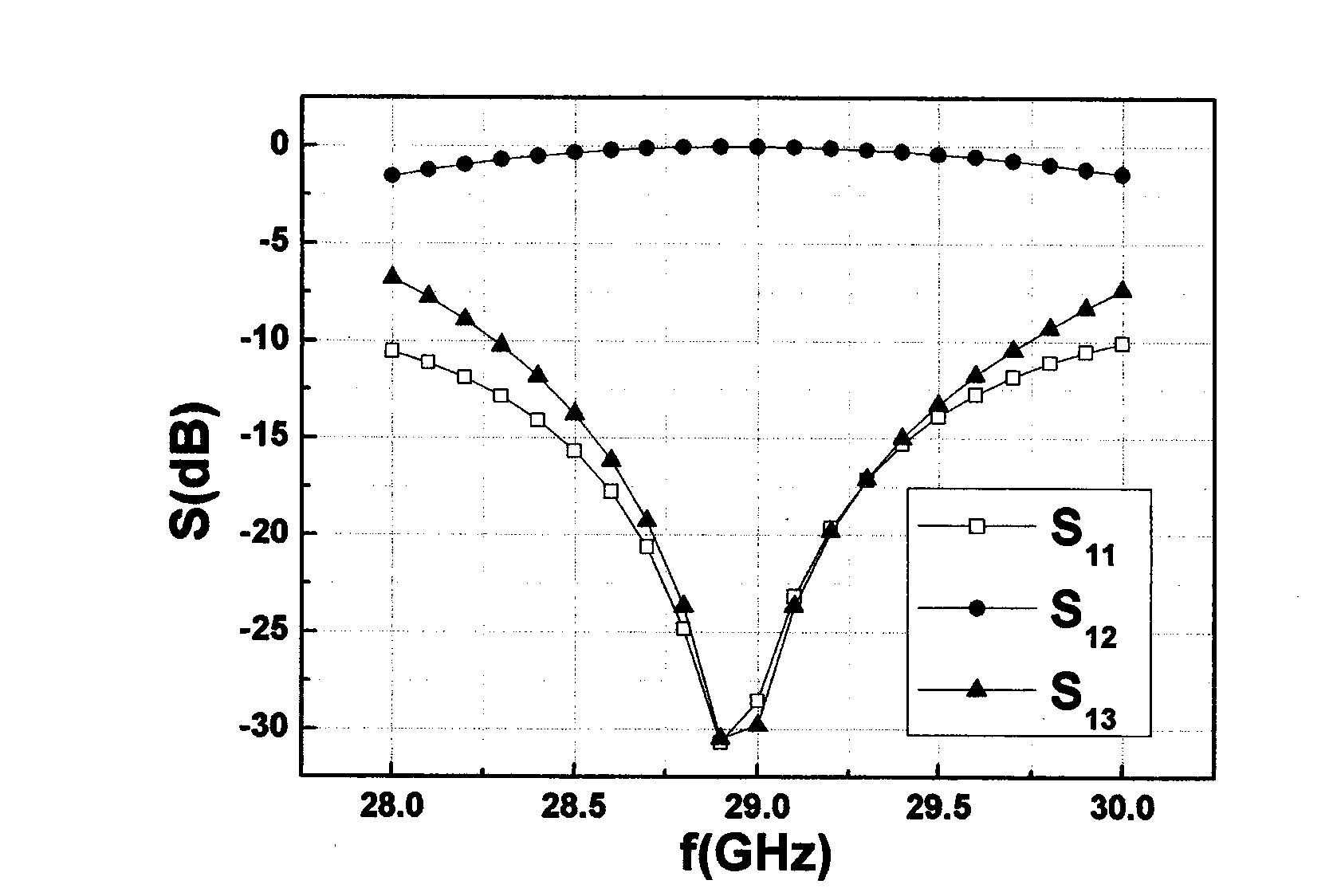

[0013] Example 1: figure 2 .It is a schematic diagram of the unfolded state of each part of the circulator in this embodiment, and the substrate 1 is made of Al 2 o 3 Ceramic material, its thickness is 200μm (micron), relative permittivity is 9.8; its bottom groove 6 radius R880μm, groove depth 150μm,; ferrite diaphragm 2 is barium ferrite, thickness is 10μm, saturation magnetization It is 2500Gs, the relative permittivity is 15, and the bias magnetic field received by the ferrite film is 10 6 A / m; the central junction 3, the matching section 4, and the grounding film 5 are all gold (Au) films with a thickness of 3 μm. The widths and lengths of the two-node wires with narrow outer ends are 400 μm, 200 μm, 160 μm, and 940 μm, respectively; the high-conductivity metal block 7 is made of silver (Ag), and its radius is the same as that of the central junction 3, which is also 880 μm , and its thickness is 150 microns.

[0014] The manufacturing method of the circulator in thi...

Embodiment 2

[0016] Example 2: Figure 4 .It is a schematic diagram of the structure of the present embodiment 2. The substrate 1 and its groove 6, the ferrite diaphragm 2, the central junction 3, and the matching section 4 are all the same as those of the embodiment 1. In this embodiment, the bottom surface of the substrate 1 and the concave A gold film with a thickness of 3 μm is evaporated on the inner surface of the groove 6, and the metal block (Ag) 7 is omitted to save some precious metals and further reduce the weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com