Self-adaptive driving circuit of active clamping switch tube

A drive circuit and clamp switch technology, which is applied in the direction of conversion equipment with intermediate conversion to AC, can solve problems such as increased faults and power loss, complex drive circuits, and difficult implementation of Td, and achieves reduced turn-off losses and simple circuits , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

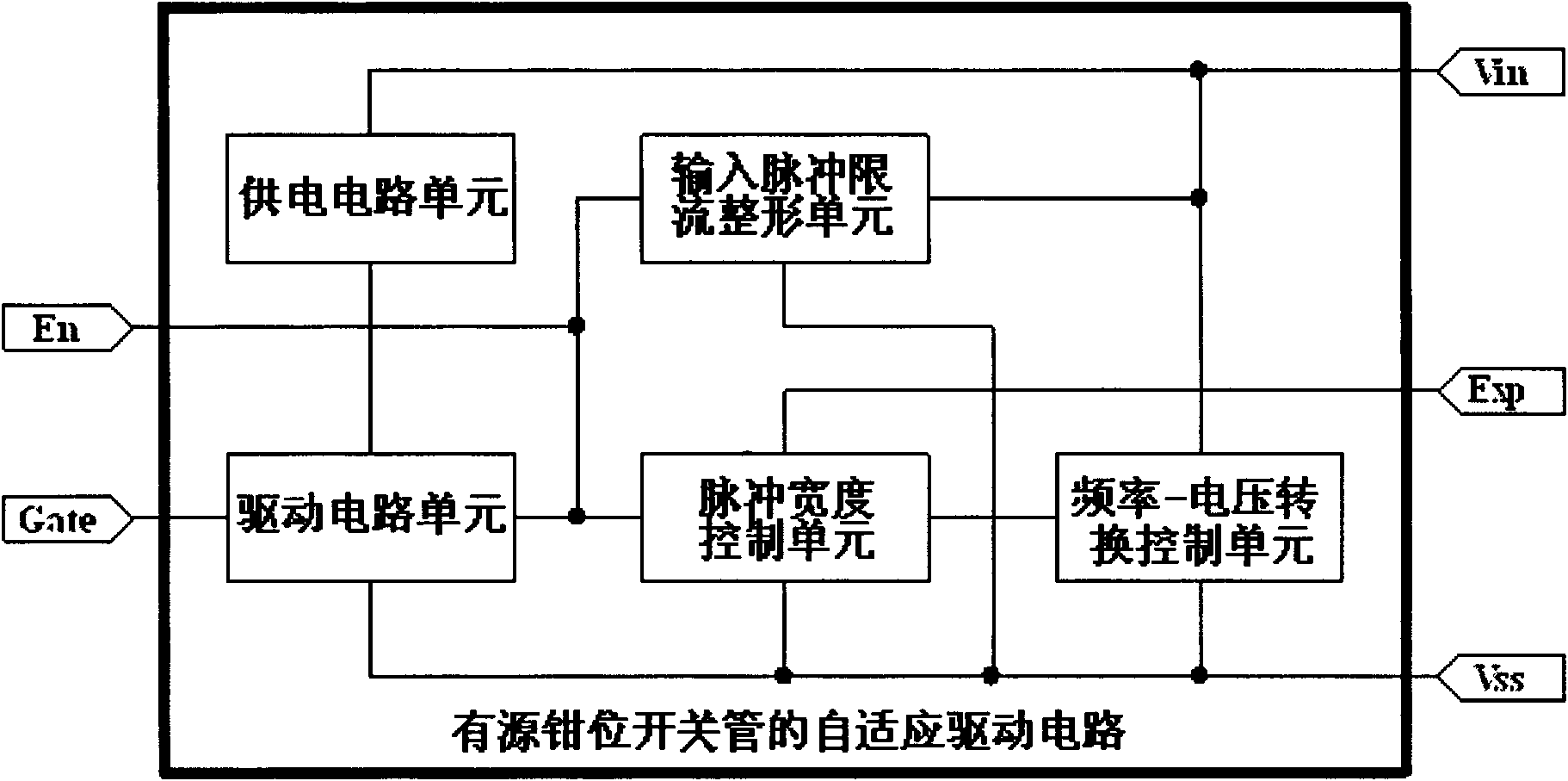

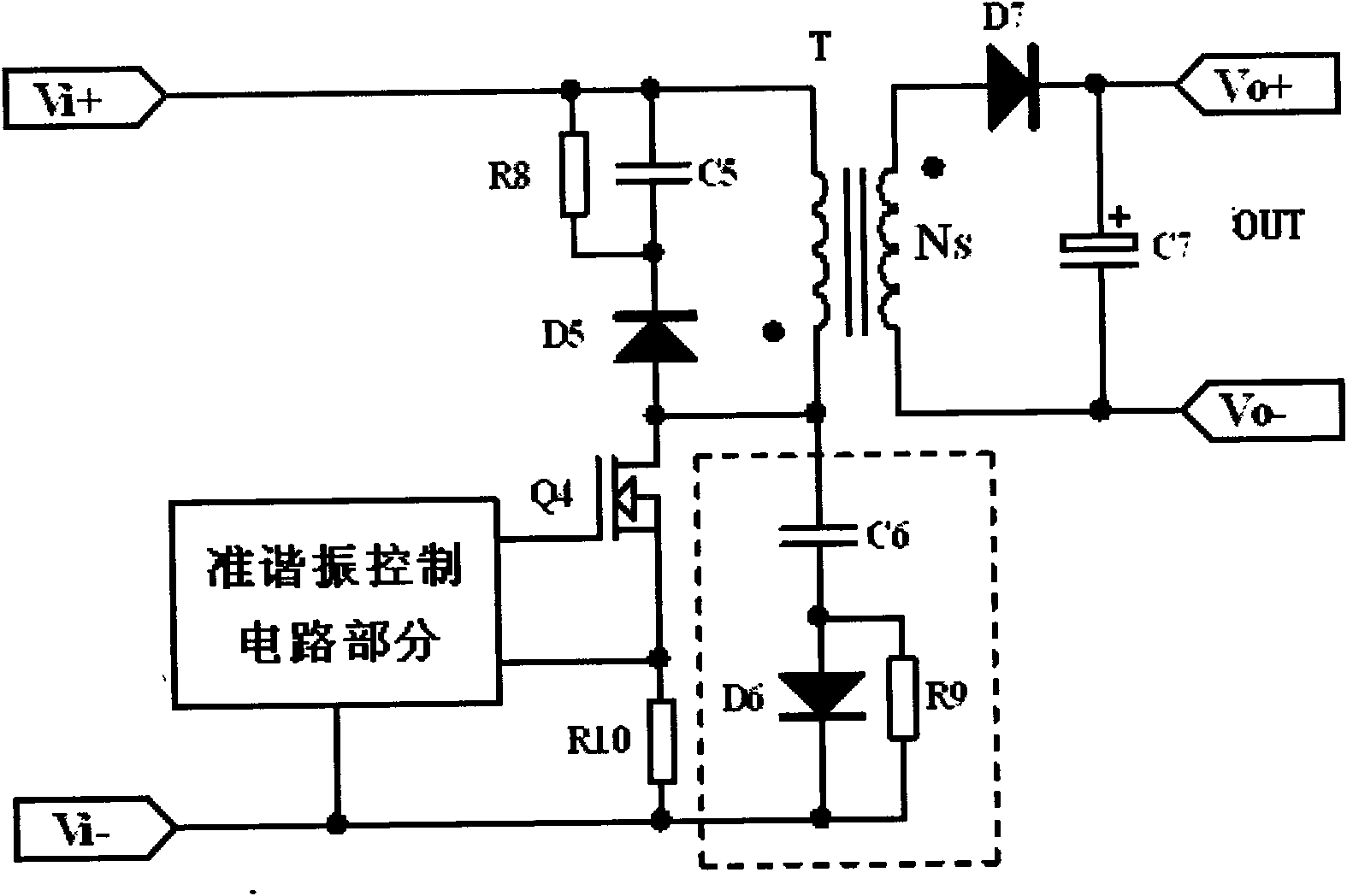

[0026] Such as figure 1 As shown, the adaptive drive circuit of the active clamp switch tube is used to drive the clamp switch tube in the switching power supply of the flyback quasi-resonant control mode to realize the active clamp function, and the circuit specifically includes: mutual electrical connection The drive circuit unit, the frequency-voltage conversion control unit, the pulse width control unit, the input pulse current limiting shaping unit and the power supply circuit unit.

[0027] The above-mentioned units form a circuit module, which includes at least three necessary ports, namely Vin, Gate and Vss, which can be conveniently applied to switching power supplies. Among them, Vin and Vss are respectively connected to both ends of the active clamp signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com