Dynamic pressure cavitation jet polishing device of colloidal flow and method

A polishing device and colloid technology, applied in explosion generating devices, grinding/polishing equipment, abrasive feeding devices, etc., can solve the problems of limited adaptability of processing workpiece materials, complex equipment, low processing efficiency, etc. Polishing quality and processing efficiency, enhanced mechanical shearing effect, improved removal efficiency

Inactive Publication Date: 2011-01-05

HARBIN INST OF TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problems of low processing efficiency, high processing cost, limited adaptability of workpiece material and complex equipment and high maintenance cost of the existing ultra-smooth surface polishing device in the existing ultra-smooth surface polishing method, Provided is a colloidal fluid flow pressure cavitation jet polishing device and method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

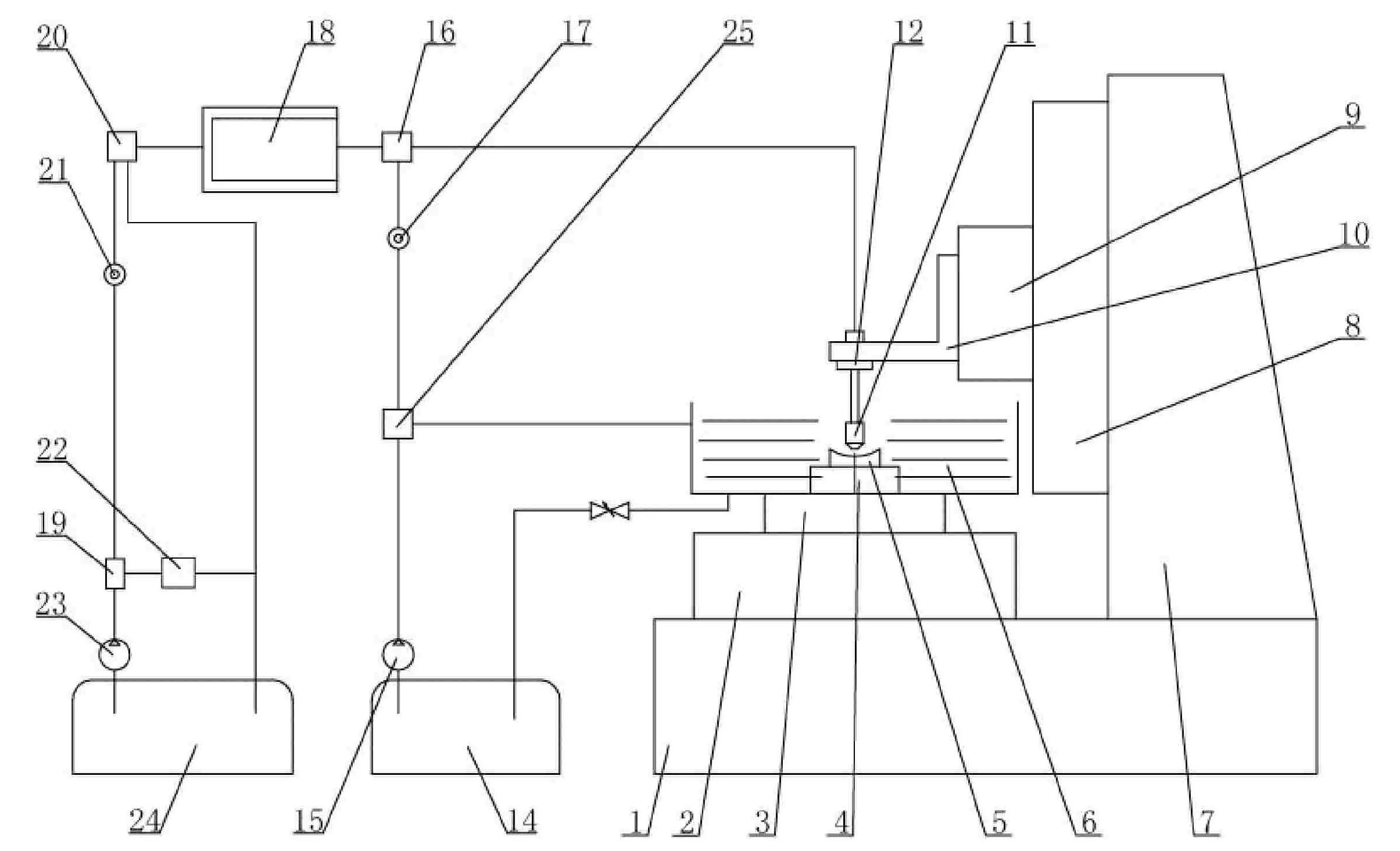

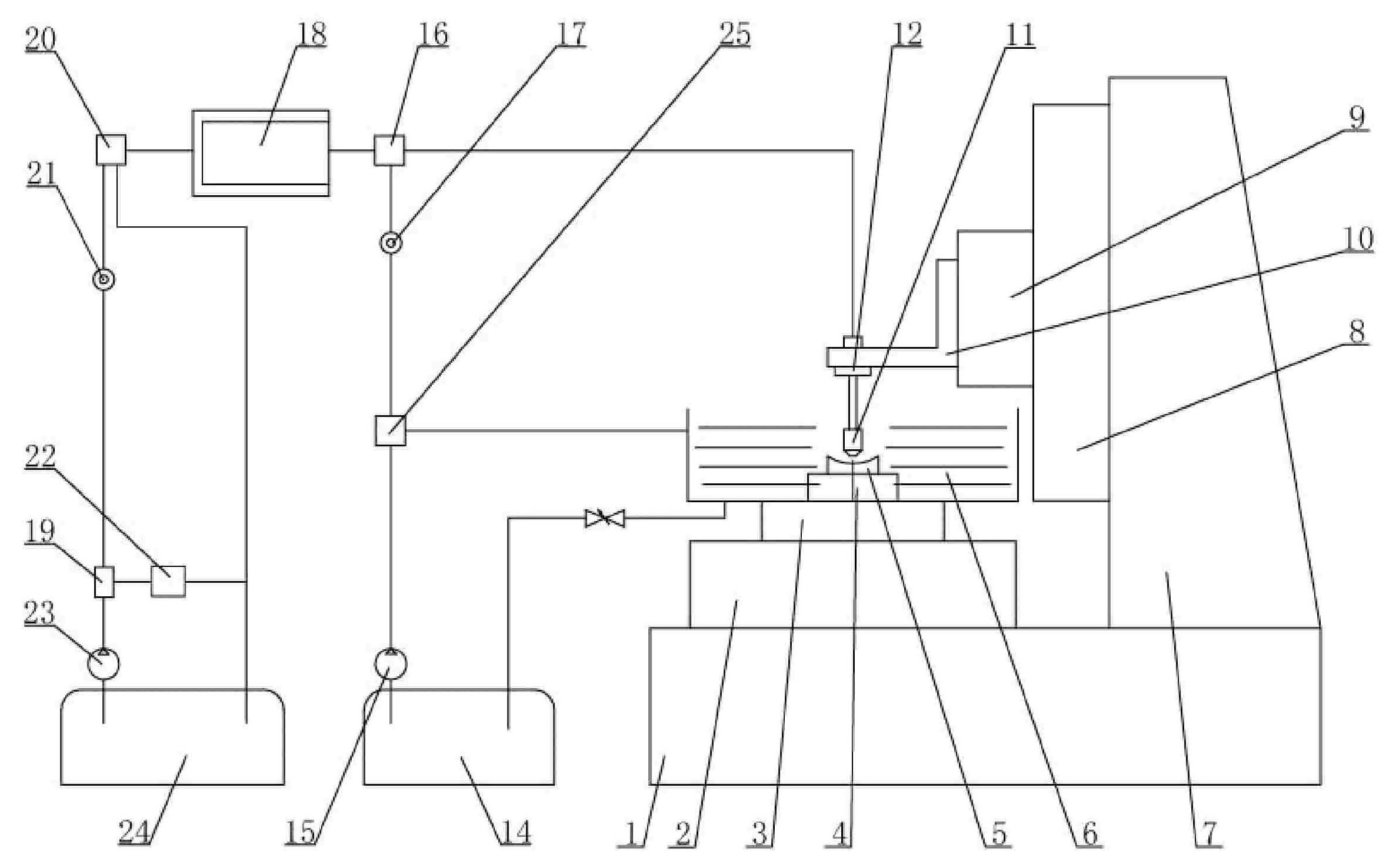

The invention discloses a dynamic pressure cavitation jet polishing device of colloidal flow and a method, relating to a polishing device and a method and aiming at solving the problems that the existing polishing method of the ultrasmooth surface has low processing efficiency and high cost, the adaptability of the work piece material is limited and the existing polishing device of the ultrasmooth surface has complex equipment and high maintenance cost. The device is characterized in that a cavitation jet device is fixed on a bracket; the input end of the cavitation jet device is connected with an outlet of a first flow reversing valve by a pipeline. The method comprises the following steps: (1) the polished work piece is immersed with 10 to 200mm by the colloidal polished liquid level; (2) the oil pressure of the cavitation jet device is 0.5 to 15MPa; (3) the cavitation jet pressure is 0.5 to 15MPa; and (4) the cavitation jet device is arranged in colloidal polishing liquid, the cavitation jet device sprays to the work piece at the speed of 15 to 250m / s, and after polishing, the work piece is taken out, namely the polished work piece. The invention is used for ultraprecise and ultrasmooth polishing of optical glass, microcrystal glass, semiconductor materials and monocrystal materials.

Description

Colloidal fluid flow pressure cavitation jet polishing device and method technical field The invention relates to a polishing device and method. Background technique With the rapid development of modern science and technology, especially cutting-edge science and technology such as aviation, aerospace, national defense, military industry, information, microelectronics and optoelectronics, modern optical systems (such as modern short-wave optics, strong light optics, etc.) and optoelectronics and thin films The scientific field has higher and higher requirements for the surface quality of the device. In order to meet its performance, the surface roughness of the device is required to be below 1nm, and the processed surface requires as small as possible surface defects and subsurface damage; such as silicon surface Minor surface roughness will affect the performance of microelectronic devices. In the next generation of ultra-large-scale integrated circuits, ultra-smooth surfa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24C3/12B24C11/00B24C5/04B24C5/00B24C7/00

Inventor 张勇张飞虎宋孝宗栾殿荣

Owner HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com