Method for preparing fiber toughness SiO2 aerogel composite material in normal pressure drying condition

A technology of atmospheric drying and composite materials, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problem of excessive equipment conditions, and achieve the effect of reducing production cost, complete block and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

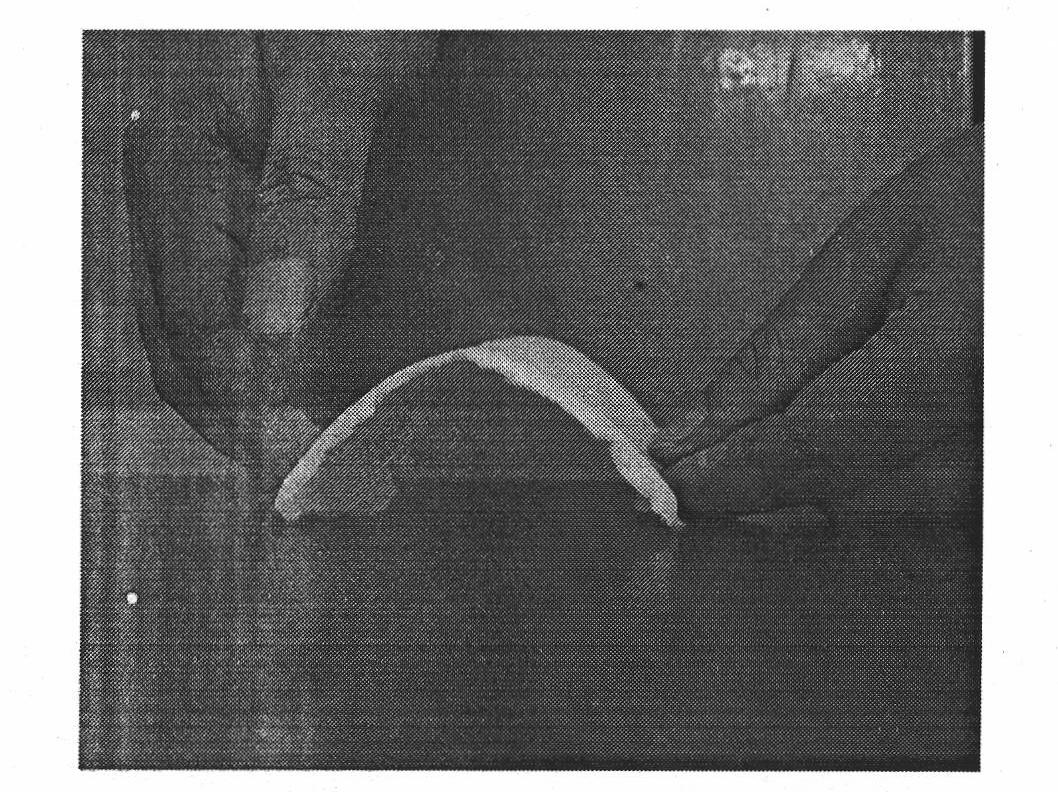

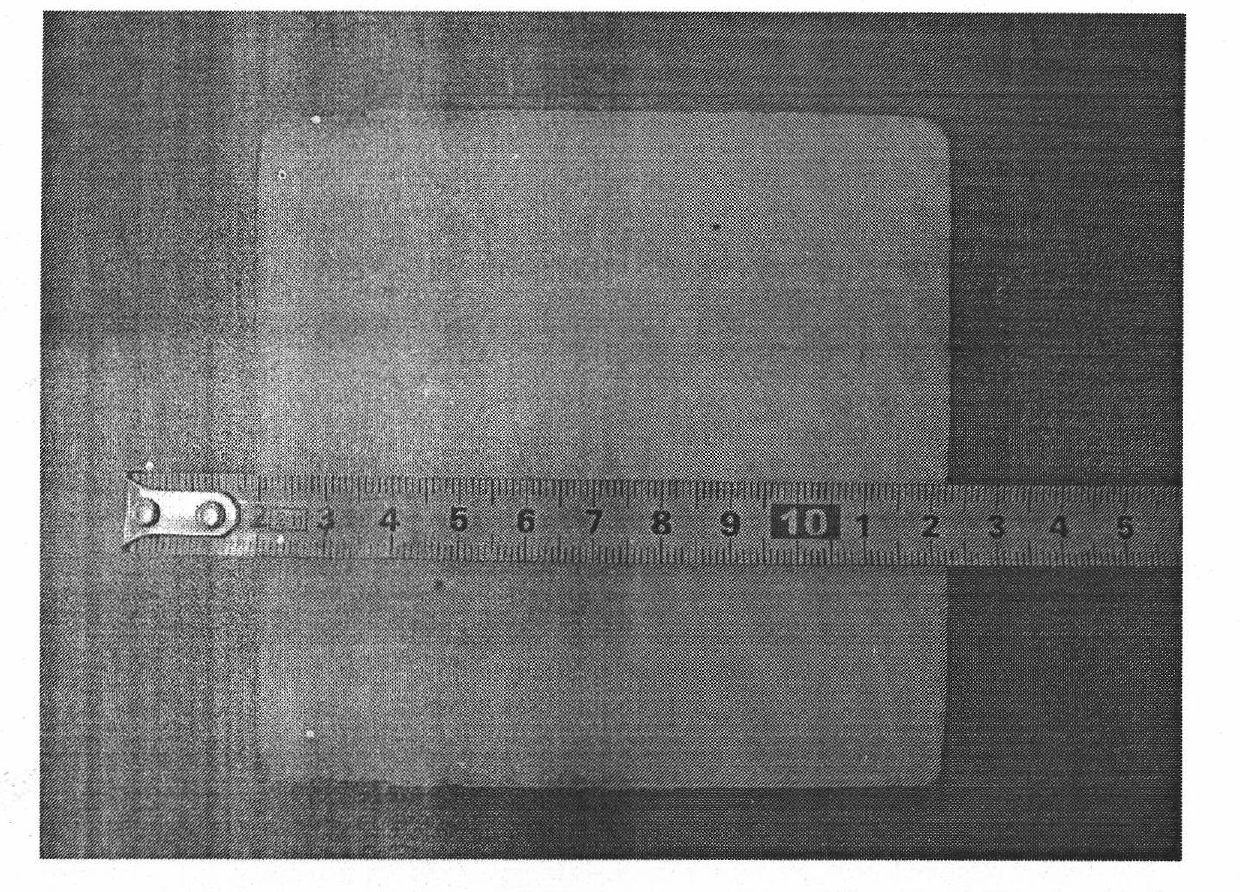

[0009] Specific implementation mode 1: In this implementation mode, dry under normal pressure to prepare fiber tough SiO 2 The method of airgel composite material is to carry out as follows: one, carry out hydrolysis reaction 48h after mixing ethyl orthosilicate, dehydrated alcohol, oxalic acid and water, wherein the mol ratio of ethyl orthosilicate and water is 1:1, the molar ratio of ethyl orthosilicate to absolute ethanol is 1:7, the molar ratio of ethyl orthosilicate to oxalic acid is 1:9×10 -4 2. Add water, N, N-dimethylformamide and ammonia water, inject the fiber mat until the fiber mat is submerged, and leave it for 24-48 hours to obtain a fiber mat-reinforced gel composite; 3. Step 2 The prepared fiber mat-reinforced gel composite is placed in a drying oven at 20-60°C for 2-6 hours, then placed in an aqueous solution of 80% ethanol by volume, and aged at 40-60°C for 12-24 hours. Then place it in a mixture of tetraethyl orthosilicate and ethanol with a volume ratio of...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the fiber mat is short quartz fiber mat, continuous quartz fiber mat, high silica fiber mat or carbon fiber mat.

specific Embodiment approach 3

[0012] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the drying temperature in Step 3 is 30-50°C. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com