Polyvinyl chloride transparent compound and tubular product thereof

A polyvinyl chloride and composition technology, applied in the field of polymer materials and transparent materials, can solve the problems of complex formula, high cost, heavy workload, etc., and achieve the effect of not easy to scale, light weight and smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

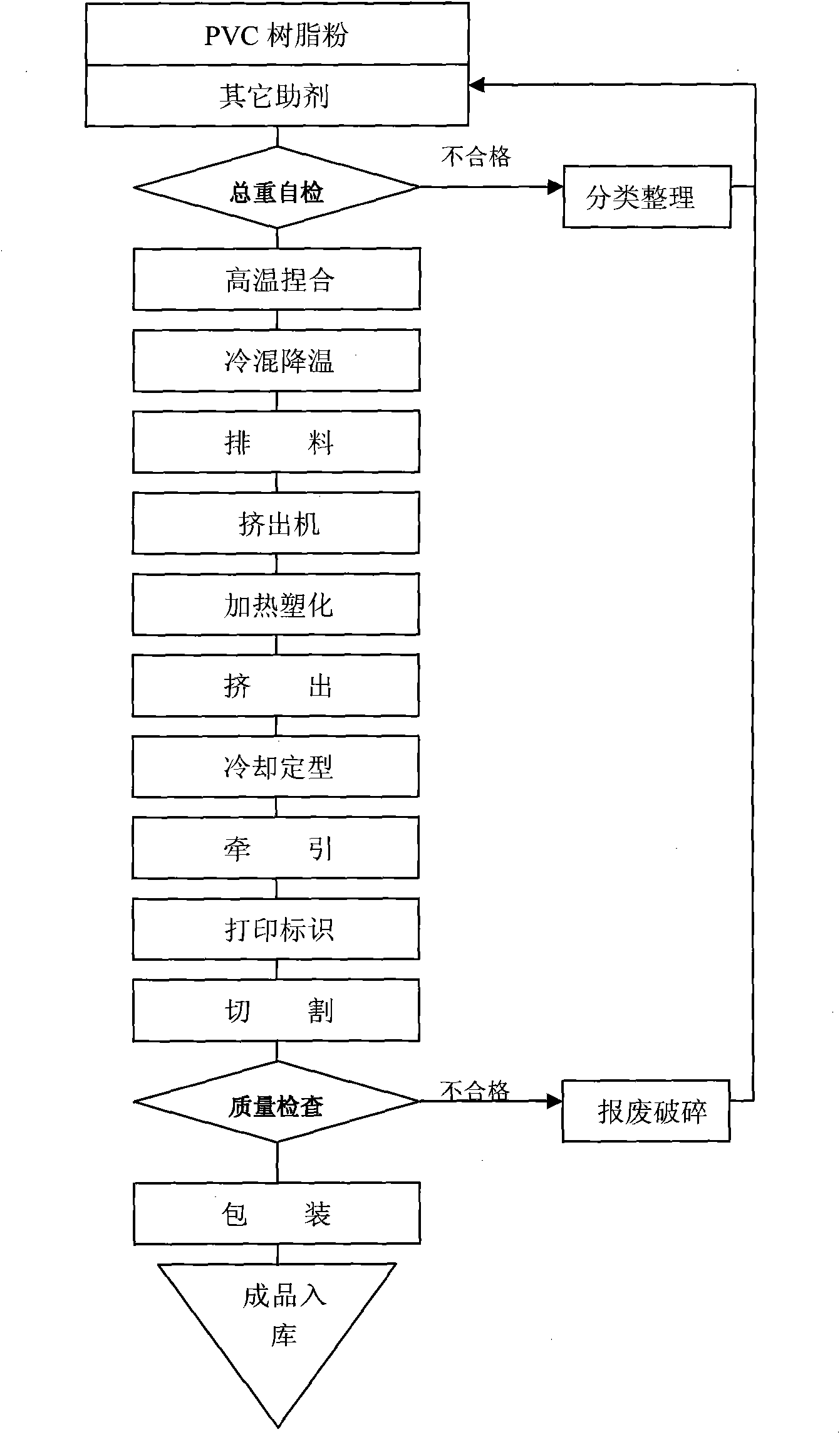

Method used

Image

Examples

Embodiment 1

[0050]The polyvinyl chloride transparent composition of the present embodiment, its each component and parts by weight thereof are as follows:

[0051] PVC resin 100;

[0052] Organotin T-178A 1.2;

[0053] B610 (impact modifier) 3;

[0054] PA-40 (processing aid) 1.0;

[0055] G60 (internal lubricant) 0.5;

[0056] Polyethylene wax (AC-6A) 0.6;

[0057] Ultramarine 0.003;

[0058] UV531 (ultraviolet absorber) 0.5;

[0059] DOP5.

[0060] Weigh the above-mentioned components and add them into the heat mixer, turn to cold mixing when the temperature is about 110°C, cool down to about 45°C and discharge to obtain a substantially uniform compound, and then extrude the obtained compound The transparent PVC pipe was extruded by a machine, and various main performance tests were performed on the obtained pipe. The test results are shown in Table 1.

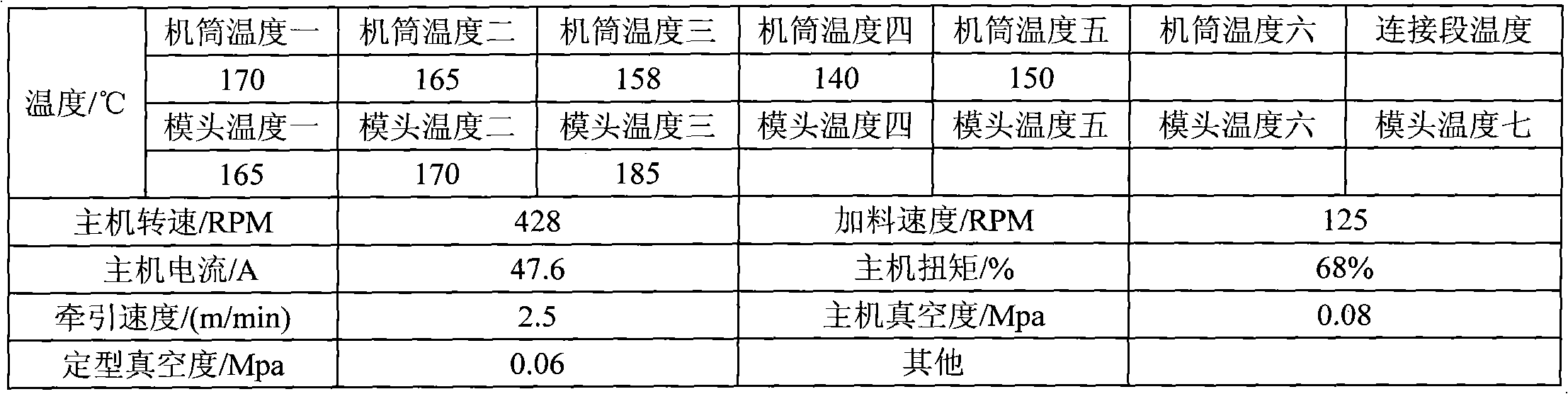

[0061] The extrusion process parameters are set as shown in Table 2.

[0062] Table 2 Extrusion process parameter settings ...

Embodiment 2

[0065] The polyvinyl chloride transparent composition of the present embodiment, its each component and parts by weight thereof are as follows:

[0066] PVC resin 100;

[0067] Organotin T-178A 1.0;

[0068] B610 (impact modifier) 4;

[0069] K400P (processing aid) 1.5;

[0070] G60 (internal lubricant) 0.5;

[0071] Polyethylene wax (AC-6A) 0.8;

[0072] Transparent blue 0.002;

[0073] UV531 0.5;

[0074] Epoxidized soybean oil 5.

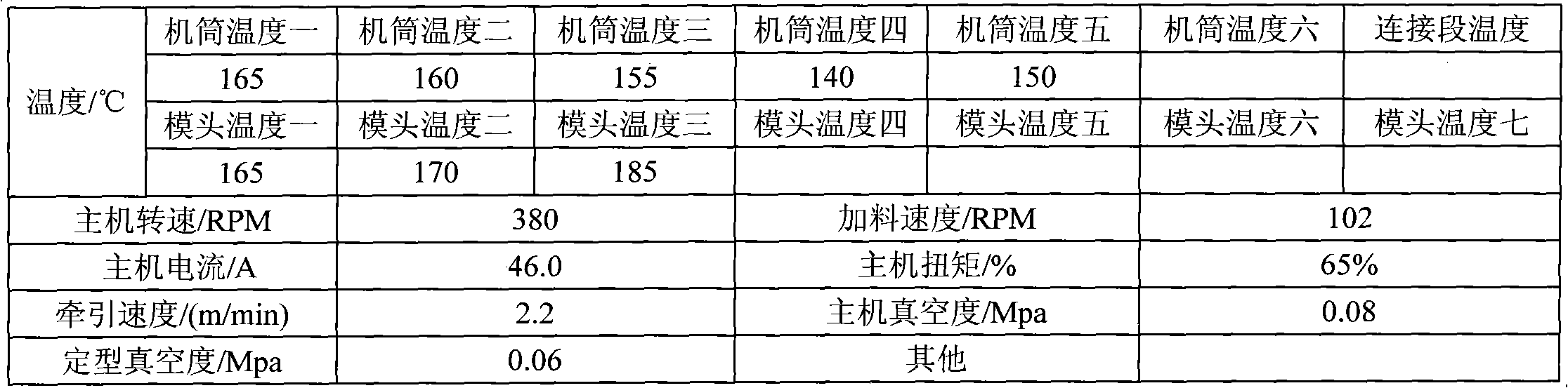

[0075] Weigh the above-mentioned components and add them into the heat mixer, turn to cold mixing when the temperature is about 110°C, cool down to about 45°C and discharge to obtain a substantially uniform compound, and then extrude the obtained compound The transparent PVC pipe was extruded by a machine, and various main performance tests were performed on the obtained pipe. The test results are shown in Table 1. The extrusion process parameters are set as shown in Table 3.

[0076] Table 3 Extrusion process parameter settings

[00...

Embodiment 3

[0079] The polyvinyl chloride transparent composition of the present embodiment, its each component and parts by weight thereof are as follows:

[0080] PVC resin 100;

[0081] Organotin T-178A 1.6;

[0082] B51 (impact modifier) 3;

[0083] K400P (processing aid) 1.2;

[0084] Oxidized polyethylene wax (AC-629) 0.3;

[0085] Polyethylene wax (AC-6A) 0.7;

[0086] Transparent blue 0.002;

[0087] UV531 0.5;

[0088] Epoxidized soybean oil 2;

[0089] DOP1.

[0090] Weigh the above-mentioned components and add them to the heat mixer, turn to cold mixing when the temperature is about 120°C, cool down to about 45°C and discharge to obtain a substantially uniform compound, and then extrude the obtained compound The transparent PVC pipe was extruded by a machine, and various main performance tests were performed on the obtained pipe. The test results are shown in Table 1. The extrusion process parameters are set as shown in Table 4.

[0091] Table 4 Extrusion process pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com