Fly ash stilled brick and preparation method thereof

A technology of fly ash and autoclaved bricks, which is applied in the field of high-volume fly ash autoclaved bricks and its preparation, which can solve the problems of energy saving and environmental protection, and the strength and performance of fly ash autoclaved bricks can not meet the requirements, etc. , to achieve the effect of low density, good shrinkage performance and good water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

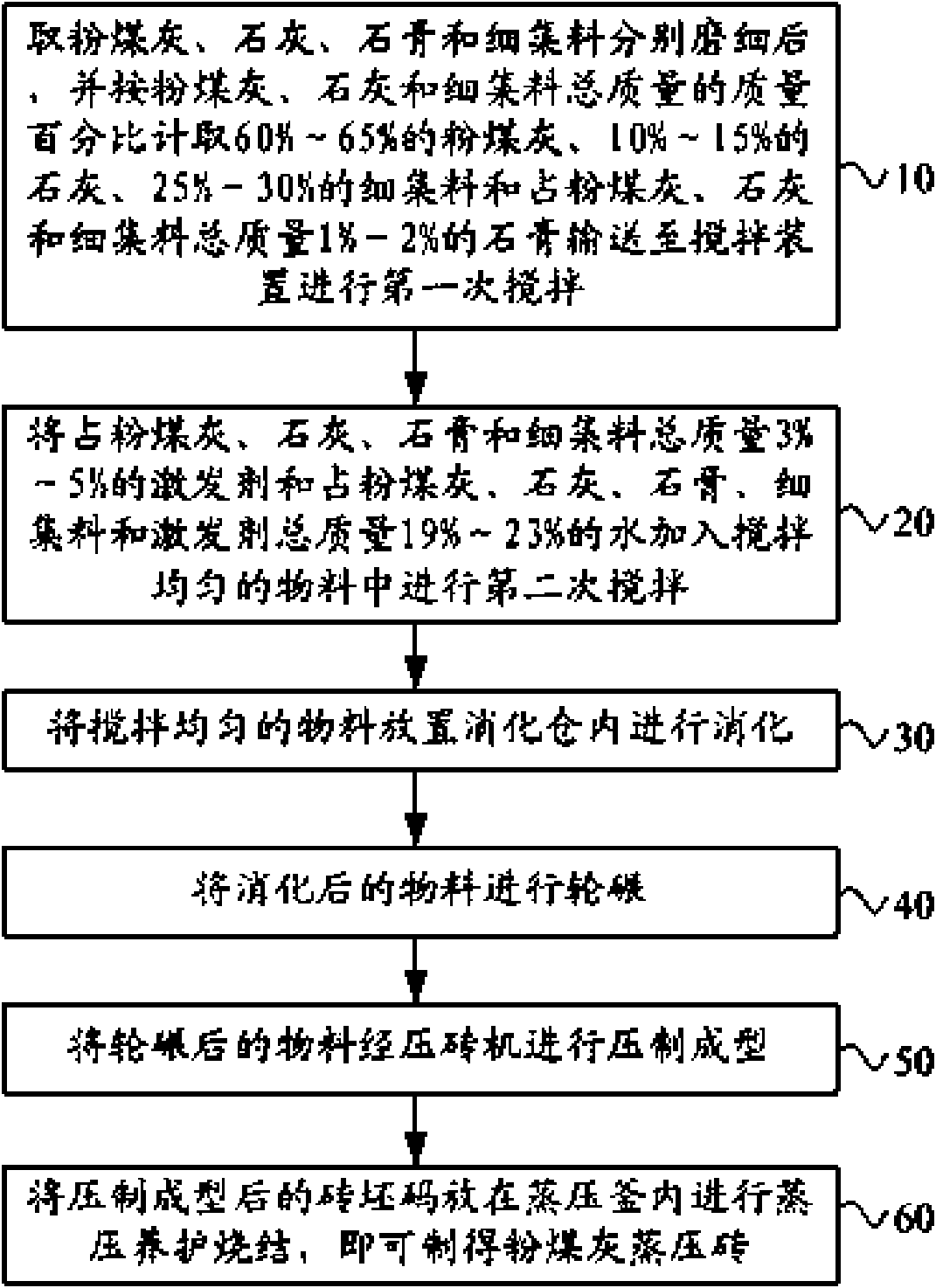

[0024] figure 1 It is a schematic flow chart of the method for preparing fly ash autoclaved bricks of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0025] Step 10, after taking fly ash, lime, gypsum and fine aggregate and grinding respectively, and taking 60% to 65% of fly ash, 10% of fly ash, lime and fine aggregate according to the mass percentage of the total mass ~15% lime, 25%~30% fine aggregate and gypsum accounting for 1%~2% of the total mass of fly ash, lime and fine aggregate are transported to the stirring device for the first stirring.

[0026] The fly ash is dry row fly ash or wet row fly ash. If the particle size of the fly ash is greater than 55 mesh, it is necessary to grind the fly ash to ≤55 mesh. If the particle size is less than or equal to 55 mesh, fine grinding of fly ash is not required. When dry fly ash is used, no treatment is required, and it is directly stored in the silo for use after entering the pl...

Embodiment 1

[0044] First, take fly ash, lime, gypsum and fine aggregate and grind them separately, and take 60% of fly ash, 10% of lime, 30% of the total mass percentage of fly ash, lime and fine aggregate % fine aggregate and gypsum accounting for 1% of the total mass of fly ash, lime and fine aggregate are transported to the twin-shaft mixer for the first mixing; then, the total mass of fly ash, lime, gypsum and fine aggregate 3% activator and 19% water accounting for the total mass of fly ash, lime, gypsum, fine aggregate and activator are added to the uniformly stirred material for the second stirring, wherein the activator is calculated according to its mass percentage Including 10% sodium sulfate, 20% calcium chloride, 10% sodium chloride and 60% carrier material, the carrier material includes 70% fly ash and 30% zeolite powder in terms of its mass percentage; Then, put the evenly stirred material in the digestion bin for 2 hours of digestion; then, the digested material is wheel-mi...

Embodiment 2

[0047] First, take fly ash, lime, gypsum and fine aggregate and grind them separately, and take 65% of fly ash, 10% of lime, 25% of the total mass percentage of fly ash, lime and fine aggregate % fine aggregate and gypsum accounting for 2% of the total mass of fly ash, lime and fine aggregate are transported to the twin-shaft mixer for the first mixing; then, the total mass of fly ash, lime, gypsum and fine aggregate 5% activator and 23% water accounting for the total mass of fly ash, lime, gypsum, fine aggregate and activator are added to the uniformly stirred material for the second stirring, wherein the activator is calculated according to its mass percentage Including 15% sodium sulfate, 30% calcium chloride, 15% sodium chloride and 40% carrier material, the carrier material includes 75% fly ash and 25% zeolite powder in terms of its mass percentage; Then, place the evenly stirred material in the digestion bin for 4 hours of digestion; then, the digested material is subjec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com