Method for manufacturing prefabricated branch cable

A manufacturing method and technology of prefabricated branches, applied in the direction of cable/conductor manufacturing, cable joints, circuits, etc., can solve the problem that insulation and sheath cannot be layered, insulation and sheath can only be injected at one time, which affects the safety of cable operation. Reliability and other issues, to achieve the effect of reducing the difficulty of production technology, enhancing safety and reliability, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

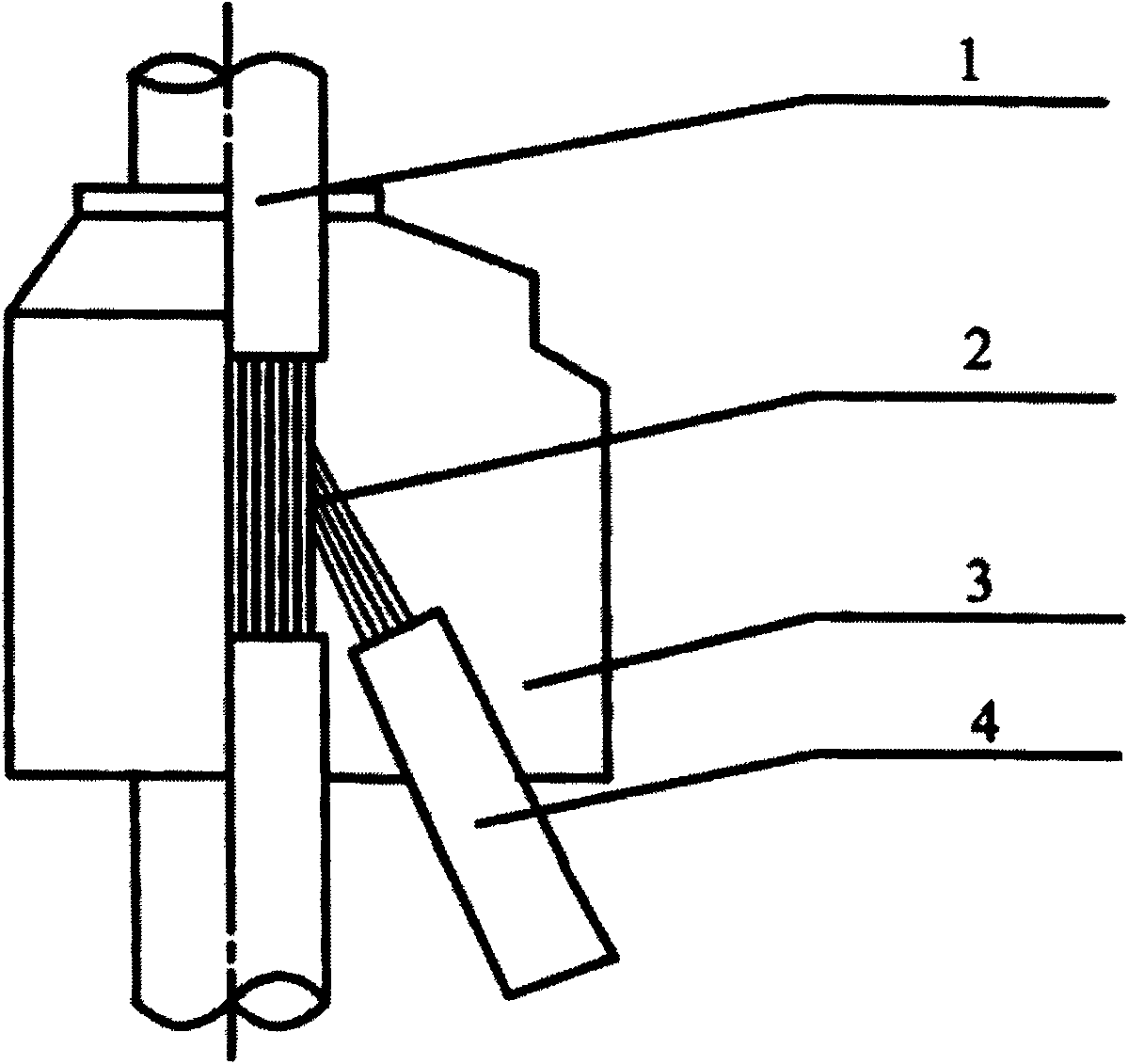

Image

Examples

Embodiment 1

[0021] Embodiment 1: VV type cable, when the insulation and sheath materials of the cable main and branch cables are the same, the process is as follows:

[0022] 1) Wrapping process: After the main cable and the branch cable are connected, use the same wrapping material as the insulation and sheath material of the main and branch cables to wrap the connection until the thickness of the wrap is the insulation and sheath of the main cable. 1.2 times the total thickness of the cover; add a layer of high-temperature-resistant polytetrafluoroethylene tape around the cladding layer, then continue to wrap a layer of glass fiber tape, and finally add a layer of soft copper tape;

[0023] 2) Heating process: heat the wrapping part to 30-50°C above the melting point of the material used, and when the insulation and sheath materials inside the wrapping layer are melted, then cool naturally to room temperature to obtain the finished product.

Embodiment 2

[0024] Embodiment 2: VV type cable, its process is:

[0025] 1) Wrapping process: After the main cable and the branch cable are connected, use the same wrapping material as the insulation and sheath material of the main and branch cables to wrap the connection until the thickness of the wrap is the insulation and sheath of the main cable. 1.8 times the total thickness of the cover; add 3 layers of high-temperature-resistant polytetrafluoroethylene tape around the cladding layer, then continue to wrap 2 layers of glass fiber tape, and finally wrap 2 layers of soft copper tape;

[0026] 2) Heating process: heat the wrapping part to 30-50°C above the melting point of the material used, and when the insulation and sheath materials inside the wrapping layer are melted, then cool naturally to room temperature to obtain the finished product.

Embodiment 3

[0027] Example 3: YJV type cable, the insulation and sheath materials of the cable main and branch cables are different, wherein the insulation is cross-linked polyethylene insulation material, and the sheath is 90°C polyvinyl chloride sheath material.

[0028] The process is:

[0029] 1) Insulation layer wrapping process: After the main cable and the branch cable are connected, use cross-linked polyethylene wrapping tape to wrap the joint until the wrapping thickness is 1.2 times the insulation thickness of the main cable; wrap the wrapping layer Add 2 layers of high-temperature-resistant plastic tape outside, then continue to wind with 1 layer of glass fiber tape, and finally wind with 1 layer of soft copper tape;

[0030] 2) Heating process of the insulating layer: heat the wrapping place to 30-50°C above the melting point of the material used, and when the insulating material inside the wrapping layer is melted, it is then naturally cooled to room temperature to fuse the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com