Film for optical use, laminate, and touch panel

A thin-film, optical technology, used in optics, optical components, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

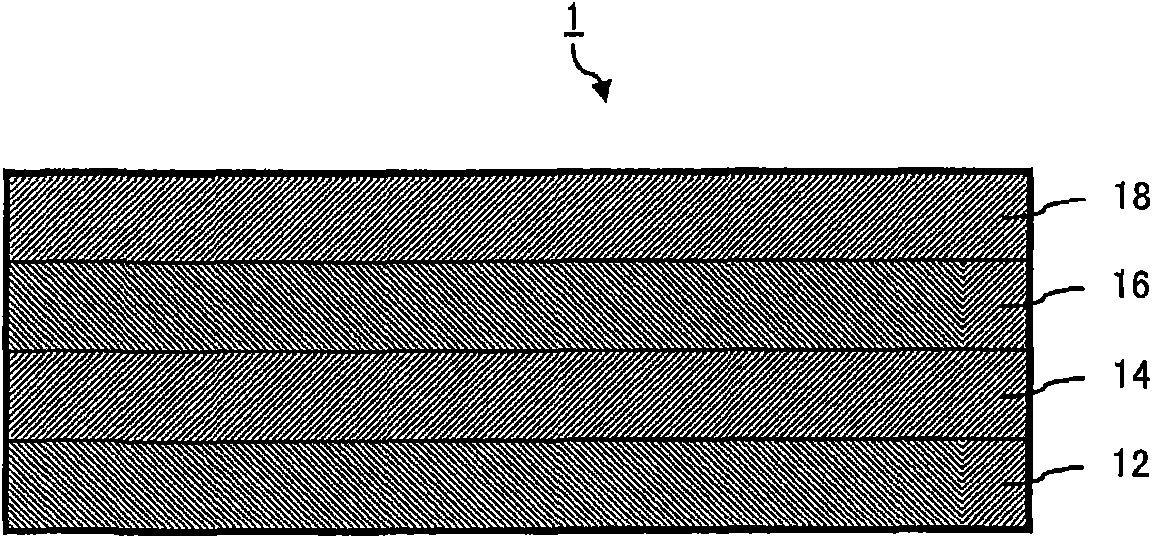

[0105] First, a coating liquid for a primer layer, a coating liquid for a clear hard coat layer, and a coating liquid for an antireflection layer are prepared.

[0106]

[0107] · Polyester resin 1 part

[0108] (elitel UE3200, UNITIKA)

[0109] · 32 parts of dilution solvent

[0110]

[0111] ・Ionizing radiation curable resin 100 parts

[0112] (Solid component 35%, Hitaloid7975, Hitachi Chemical Co., Ltd.)

[0113] ·Photopolymerization initiator 1 part

[0114] (IRGACURE184, CIBASPECIALTY CHEMICALSK)

[0115] ·Dipentaerythritol hexaacrylate 12 parts

[0116] In addition, Hitaloid 7975 contained in the coating liquid for a clear hard coat layer contains acryl acrylate as a main oligomer component of the prepolymer.

[0117]

[0118] ・Silica sol (silicon dioxide component: 10%) 200 parts

[0119] · 250 parts of porous silica microparticle dispersion

[0120] (Silica component: 5%, average particle size: 55nm)

[0121] · 350 parts of isopropanol

[0122] · 350 p...

experiment example 2

[0136] A coating liquid was prepared under the same conditions as in Experimental Example 1 except for using a coating liquid for a clear hard coat prepared according to the following recipe, and a film sample was obtained. Furthermore, the same measurement and evaluation as in Experimental Example 1 were performed. The results are shown in Table 1.

[0137]

[0138] ・10 parts of ionizing radiation curable resin

[0139] (BEAMSET 575, Arakawa Chemical Industry Co., Ltd.)

[0140] ·Photopolymerization initiator 0.5 parts

[0141] (IRGACURE 184, CIBA JAPAN Corporation)

[0142] · 10 parts of diluting solvent

[0143] In addition, BEAMSET575 contained in the coating liquid for clear hard-coat layers contains urethane acrylate as a main oligomer component of a prepolymer.

[0144] In this experimental example, the prepared transparent hard coat coating liquid is applied to the bottom layer 14 by the bar coating method, and dried to form a coating film, and the coating film ...

experiment example 3

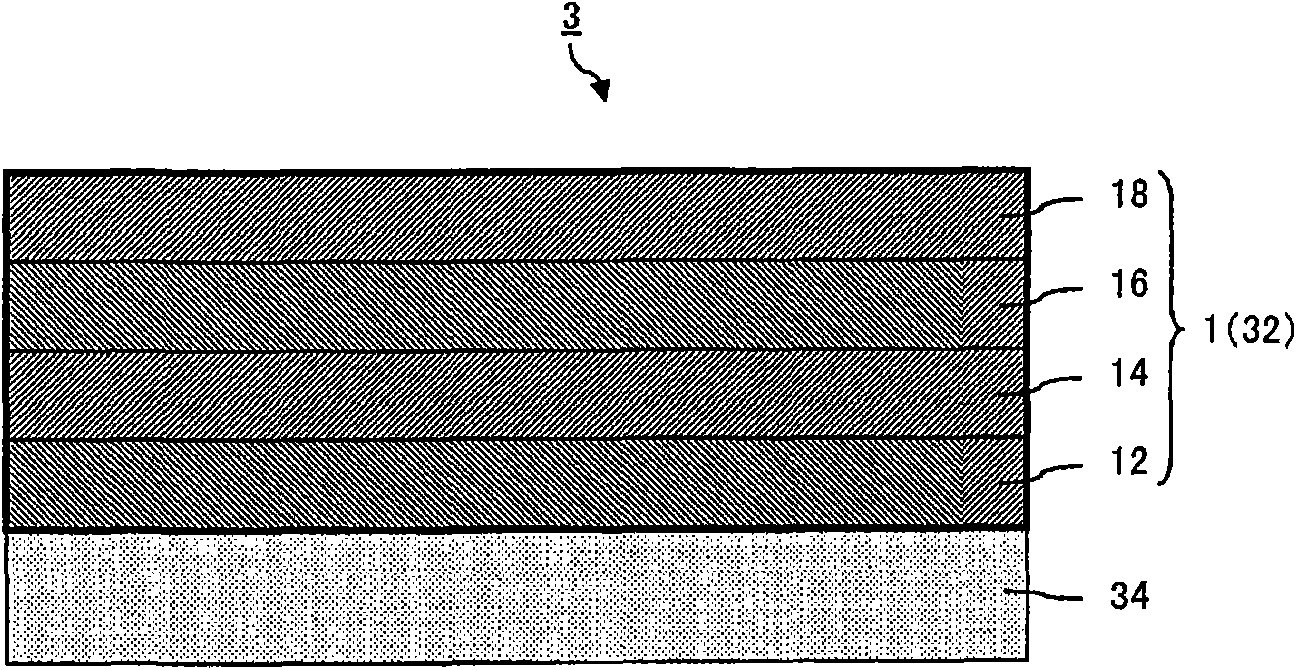

[0146] Except for using a transparent polymer film (polyethylene naphthalate, refractive index: 1.75) with a thickness of 100 μm as the transparent base layer 12, the coating liquid was prepared under the same conditions as in Experimental Example 1 to obtain a film. sample. The same measurement and evaluation as in Experimental Example 1 were performed. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com