Methods for stripping material for wafer reclamation

A technology of composition and surfactant, applied in the direction of photosensitive material processing, chemical instruments and methods, drilling composition, etc., can solve the problems that the incineration system cannot accept wastewater samples, damage the construction materials of the incinerator, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

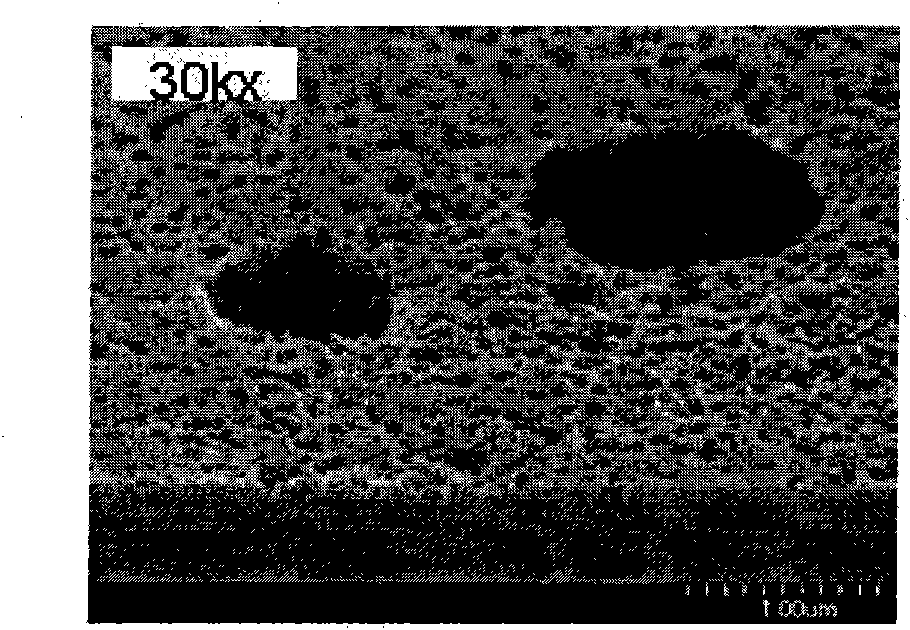

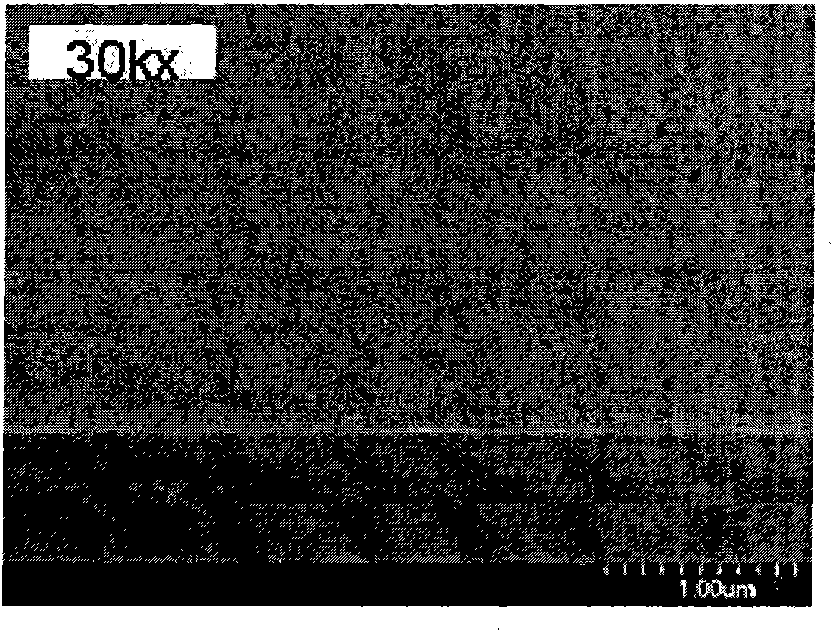

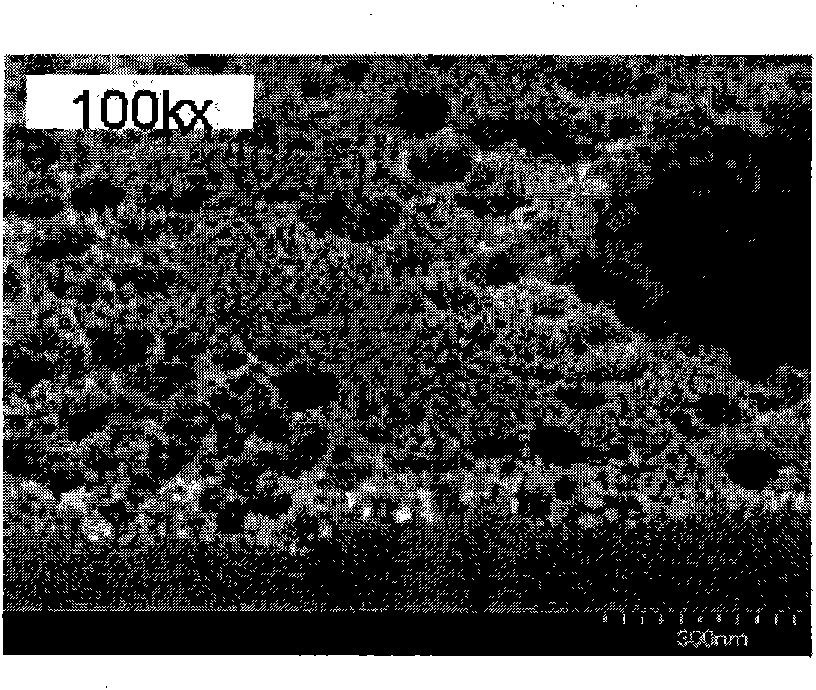

Image

Examples

Embodiment 1

[0282] In order to make the removal composition comply with national and international environmental standards, the diethylene glycol butyl ether component (which is HAP) of the removal composition is replaced by a solvent not on the HAP list (especially propylene glycol, dipropylene glycol and its ether) . Each formulation included 20.1 wt% HF, 2.2 wt% sulfolane, 21.7 wt% non-HAP listed solvent and 56 wt% water, based on the total weight of the composition. Compositions are shown in Table 1 below along with specific non-HAP inventory solvents. In each case, at 50°C will include Black Diamond (hereinafter BD, thickness approx. ) or CORAL (thickness approx. ) were immersed in a volume of the composition for 5 minutes (unless otherwise stated) and visually inspected.

[0283] Table 1: Chemical Formulations Including Non-HAP Listed Organic Solvents

[0284] Non-HAP List Organic Solvents

[0285] The etch results indicated that formulation UU including dipropylene ...

Embodiment 2

[0287] Known to include oxidizing agents (such as H 2 o 2 ) removal compositions may be relatively unstable in the presence of certain organic components. Therefore, it is often necessary to add an oxidizing agent to the remaining components at the time of use, which may be inconvenient to the user. Therefore, the more stable oxidizing agent (rather than H 2 o 2 ) was experimentally determined to have Efficacy of copper removal for blanketed wafers of 1000 mm thickness where the wafers were immersed in the solutions of Table 2 at room temperature or at 40 °C and visually inspected.

[0288] Table 2: Copper removal using various oxidizing agents

[0289] oxidizing agent

[0290] It can be seen that the order of etching rate effect is H 2 o 2 2 o 2 (or with H 2 o 2 together), depending on the needs of the user and the effect of various oxidizing agents on the materials on the structure of the microelectronic device.

Embodiment 3

[0292] Blanketed polysilicon was immersed in green formulations of the invention (G1-G4) and the polysilicon etch rate of the green formulations was determined compared to that observed for formulation CC (ie, non-green formulations). min -1 for about min -1 . Furthermore, it should be noted that the COD of the green formulation is about 60 times lower than that of the formulation CC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com