Additive composite for eliminating formaldehyde in adhesive and preparation method thereof

An additive and composition technology, applied in the direction of adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve problems such as eye irritation, eye irritation, and life-threatening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

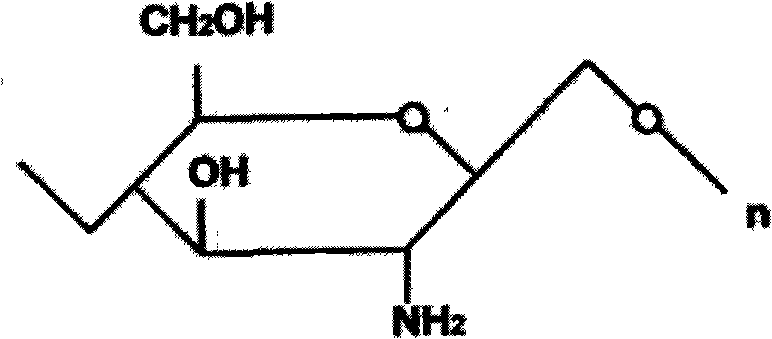

Method used

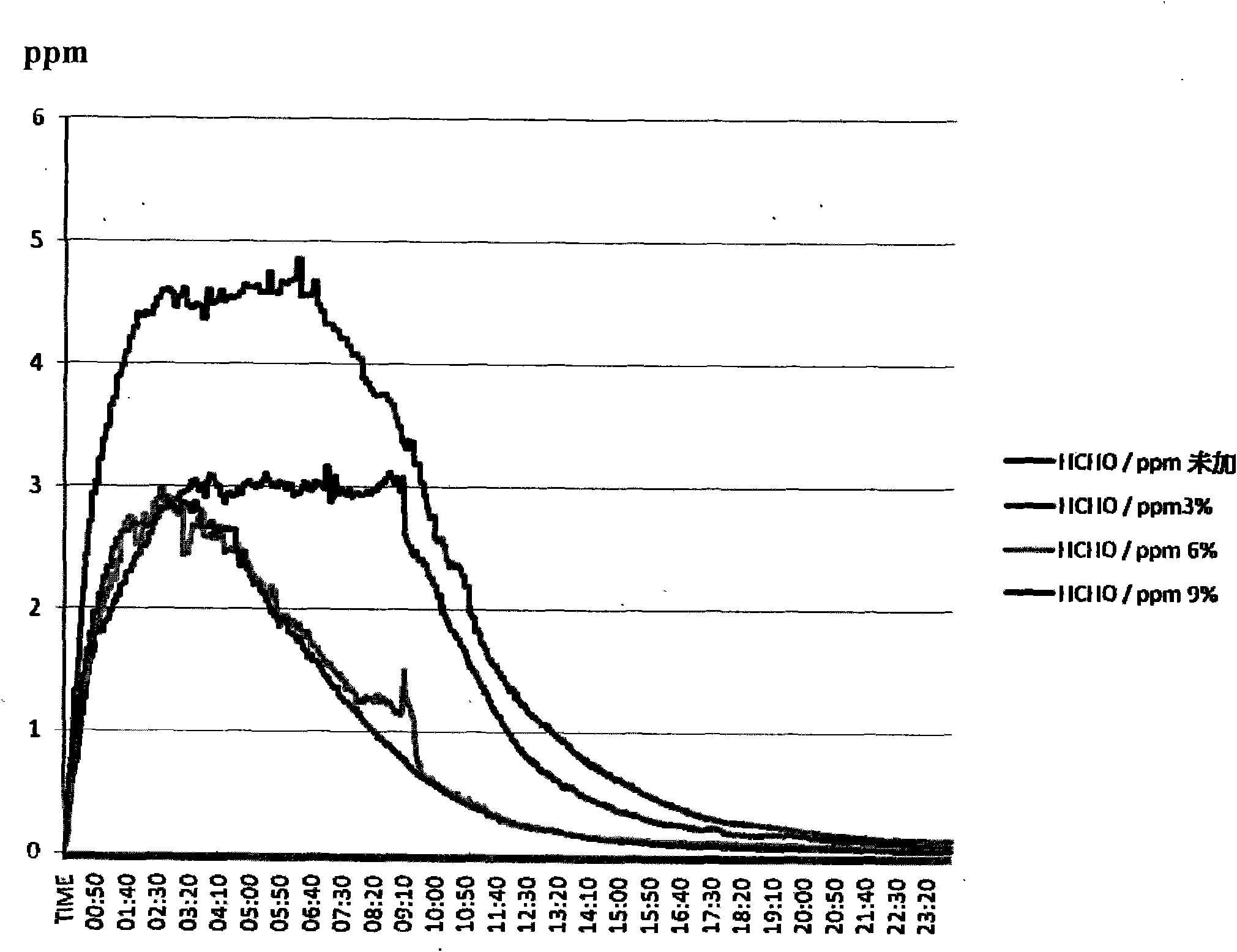

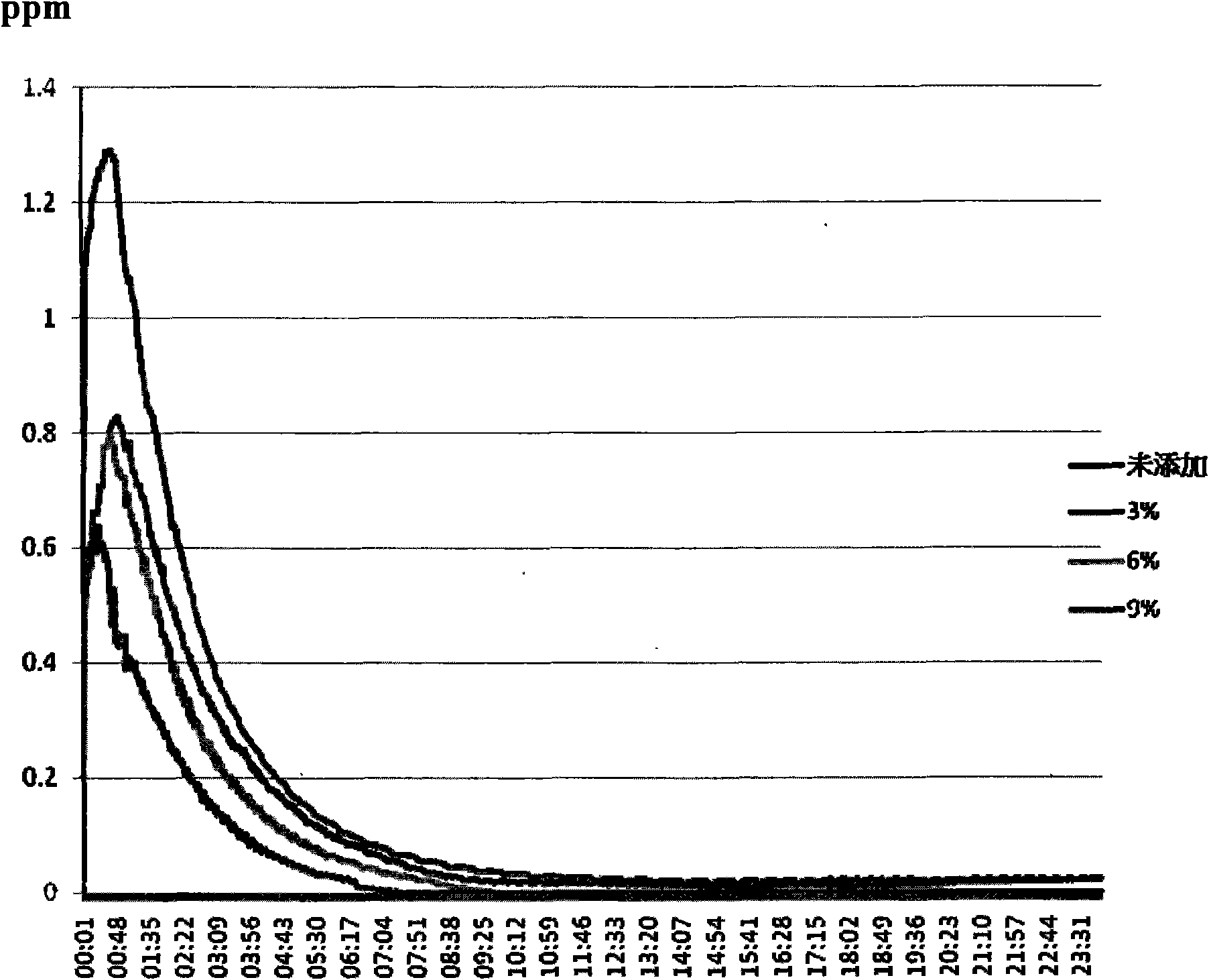

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 additive composition of the present invention

[0038] Weigh each raw material according to the following weight (unit: kg):

[0039] Chitin 3, organic acid 2, aseptic acid 2, potassium persulfate 1, alkyl polyoxyethylene ether sulfate 0.5, alkyl sulfate 1.0, polyoxyethylene alkyl ether 0.5, water 90;

[0040] Chitin and a certain amount of water (the amount of water is enough to fully dissolve chitin in it) are mixed and placed in the first stirring tank for about 20 minutes of preliminary mixing and stirring until the chitin is completely dissolved and does not precipitate, and the chitin is obtained. Vegetable base solution, set aside; mix the organic acid and the remaining water in the second stirring tank for about 15 minutes of preliminary mixing and stirring, then add ascorbic acid in the continuous stirring operation and continue stirring for about 15 minutes, then Slowly add potassium persulfate accounting for 6 / 7 of the total wei...

Embodiment 2

[0041] Embodiment 2 Preparation of the additive composition of the present invention

[0042] Weigh each raw material according to the following weight (unit: kg): chitin 10, organic acid 12, aseptic acid 8, potassium persulfate 6, alkyl polyoxyethylene ether sulfate 1.5, alkyl sulfate 2.0, polyoxyethylene Vinyl ether 1.0, water 59.5;

[0043] Chitin and a certain amount of water (the amount of water is enough to fully dissolve chitin in it) are mixed and placed in the first stirring tank for about 20 minutes of preliminary mixing and stirring until the chitin is completely dissolved and does not precipitate, and the chitin is obtained. Vegetable base solution, set aside; mix the organic acid and the remaining water in the second stirring tank for about 15 minutes of preliminary mixing and stirring, then add ascorbic acid in the continuous stirring operation and continue stirring for about 15 minutes, then Slowly add potassium persulfate accounting for 6 / 7 of the total weight...

Embodiment 3

[0044] Embodiment 3 Preparation of the additive composition of the present invention

[0045] Each raw material was weighed according to the following weight (unit: kg): chitin 6, organic acid 8, ascorbic acid 4, potassium persulfate 3, alkyl polyoxyethylene ether sulfate 1.0, alkyl sulfate 1.5, polyoxyethylene Vinyl ether 0.8, water 75.7;

[0046] Chitin and a certain amount of water (the amount of water is enough to fully dissolve chitin in it) are mixed and placed in the first stirring tank for about 20 minutes of preliminary mixing and stirring until the chitin is completely dissolved and does not precipitate, and the chitin is obtained. Vegetable base solution, set aside; mix the organic acid and the remaining water in the second stirring tank for about 15 minutes of preliminary mixing and stirring, then add ascorbic acid in the continuous stirring operation and continue stirring for about 15 minutes, then Slowly add potassium persulfate to ensure that there is no incomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com