Anti-noise fiber material cushion and preparation method thereof

A fiber material and anti-noise technology, applied in the field of fiber material pads with full-frequency noise reduction function and their preparation, to achieve the effects of noise reduction, good application effect and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

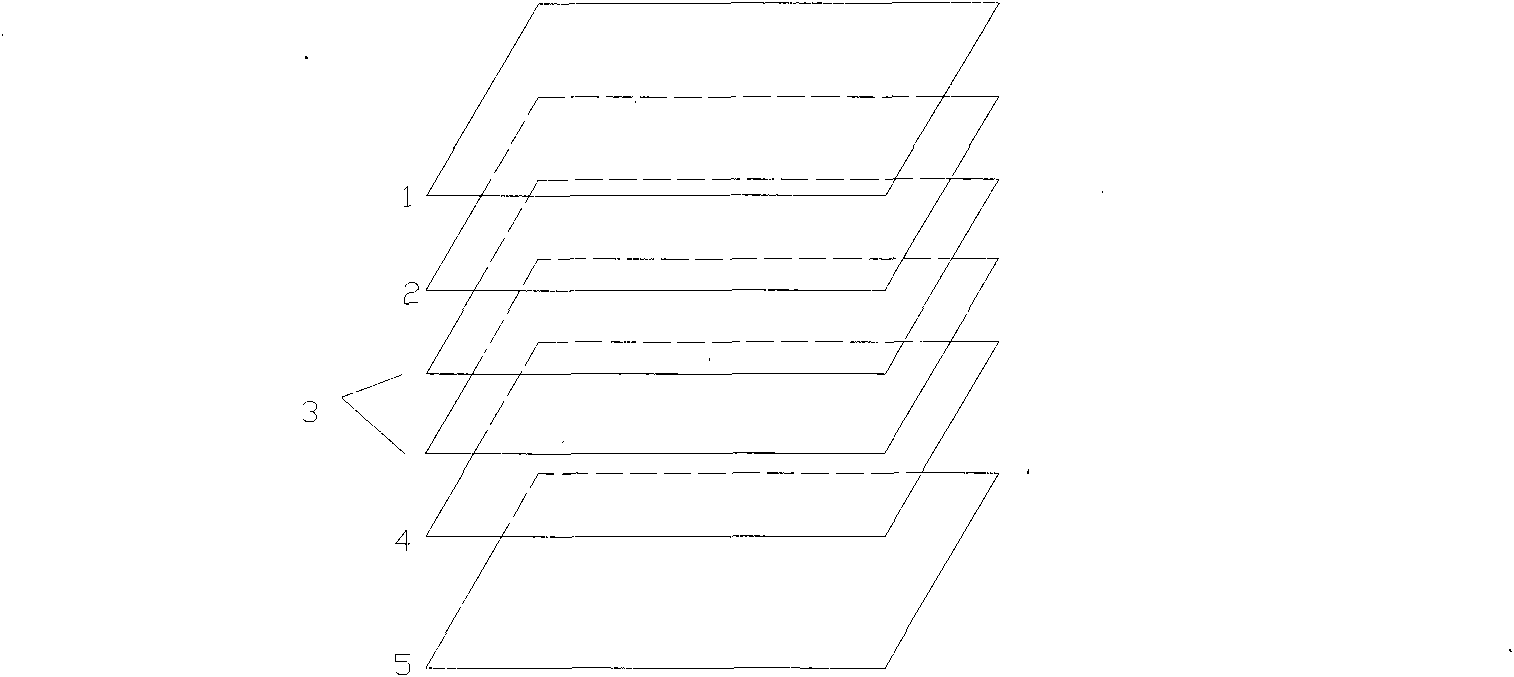

Method used

Image

Examples

Embodiment 1

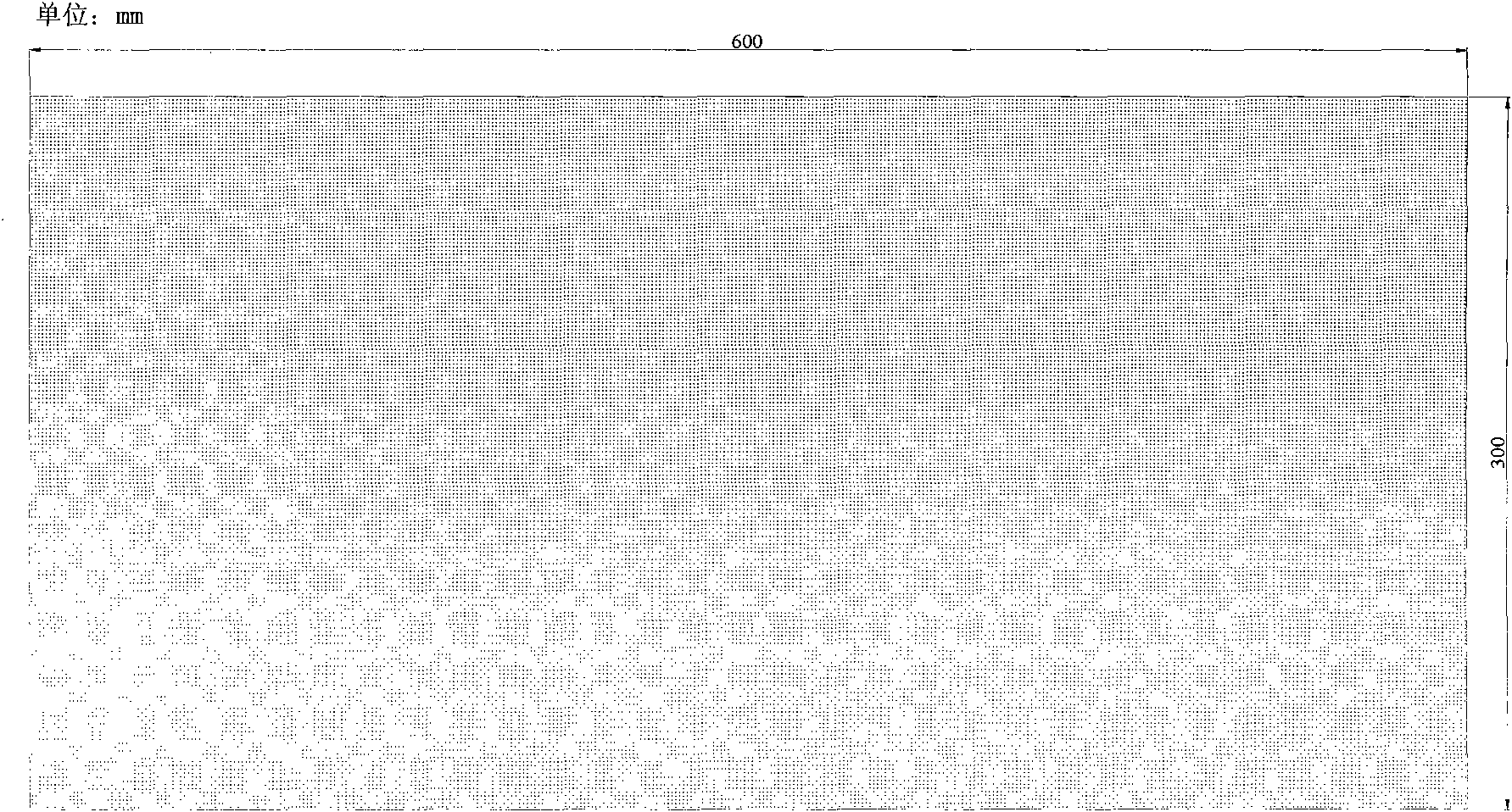

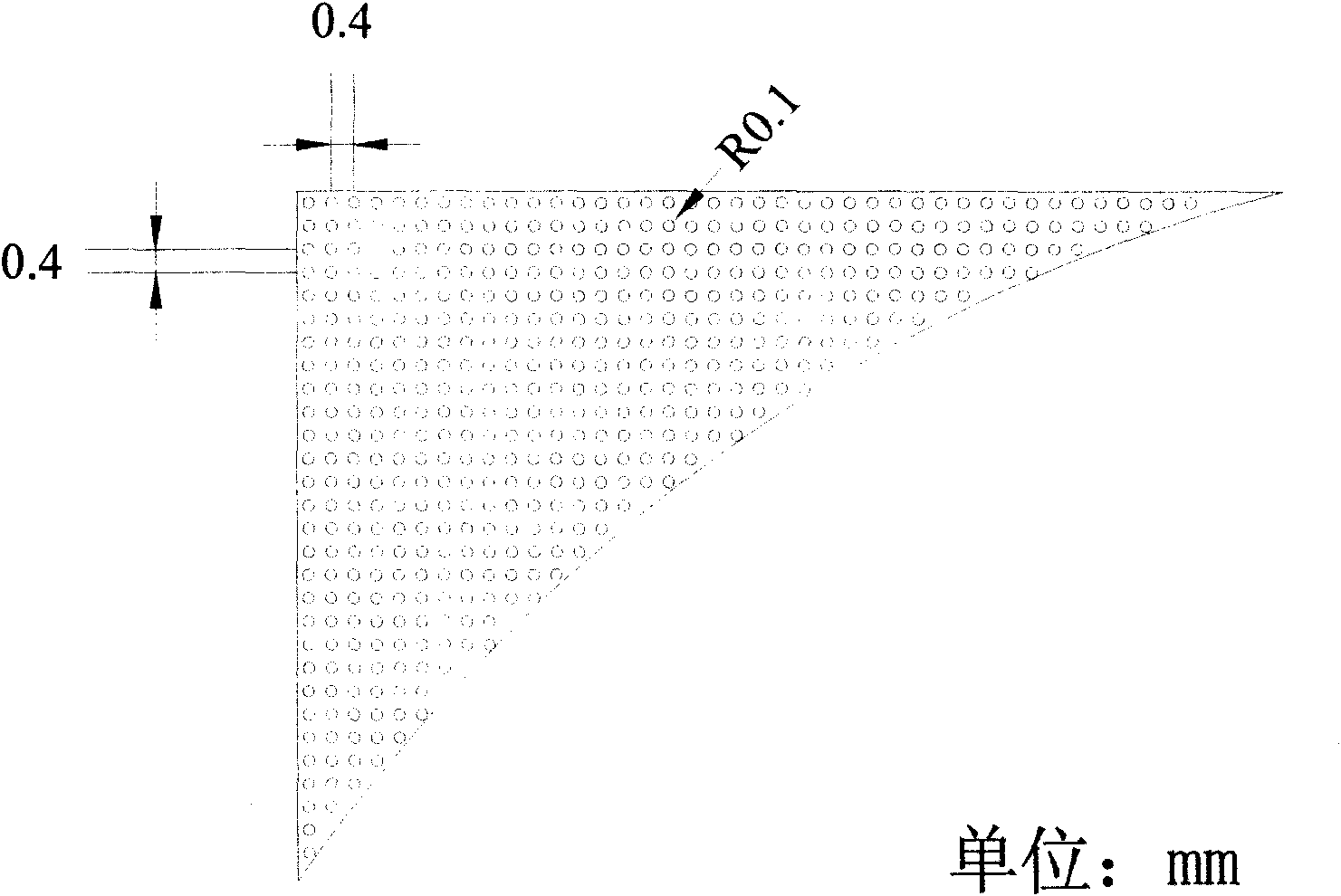

[0035] A preparation method of an anti-noise fiber material pad, comprising the following steps and process conditions:

[0036](1) Preparation of ultra-thin fiber sound-absorbing material: Dissociate the main fiber material with a pressure disc mill, and by weight percentage, the main fiber material is made of 70% pine fiber, 23% alkali-free glass fiber (specification: length 15mm × The fineness is 12um, produced by Shijiazhuang Hongweijie Trading Co., Ltd.) and 7% mineral wool fiber (specification: particle diameter ≤ 30mm, produced by Langfang Qiyuan Refractory and Energy-saving Materials Co., Ltd.). In the main fiber material, add crystalline cellulose (model HW325, produced by Henan Province So Chemical Co., Ltd.) accounting for 0.8% of the dry main fiber material weight, and add 0.3% nanometer calcium carbonate (model MCA3000, Shanghai Zhizhen Chemical Co., Ltd.) and 0.7% magnesium hydroxide (model: TIGER-B15, produced by Dongguan Daoer Chemical Co., Ltd.), blending modi...

Embodiment 2

[0043] A preparation method of an anti-noise fiber material pad, comprising the following steps and process conditions:

[0044] (1) Preparation of ultra-thin fiber sound-absorbing material: Dissociate the main fiber material with a pressure disc mill, and the main fiber material is composed of 64% poplar fiber and 23% alkali-free glass fiber (specification: length 12mm) × Fineness 12um, produced by Shijiazhuang Hongweijie Trading Co., Ltd.) and 13% mineral wool fiber (specification: particle diameter ≤ 30mm, produced by Langfang Qiyuan Refractory and Energy-saving Materials Co., Ltd.). In the main fiber material, add crystalline cellulose (model HW325, produced by Henan Province So Chemical Co., Ltd.) accounting for 0.9% of the dry main fiber material weight, and add 0.8% nanometer calcium carbonate (model MCA3000, Shanghai Zhizhen Chemical Co., Ltd.) and 1.1% magnesium hydroxide (model: TIGER-B15, produced by Dongguan Daoer Chemical Co., Ltd.), blending modification; and the...

Embodiment 3

[0049] A method for preparing a novel anti-noise fiber material pad, comprising the following steps and process conditions:

[0050] (1) Preparation of ultra-thin fiber sound-absorbing material: Dissociate the main fiber material with a pressure disc mill, and by weight percentage, the main fiber material consists of 63% non-wood straw fiber, 21% alkali-free glass fiber (specification: length 12mm×12um fineness, produced by Shijiazhuang Hongweijie Trading Co., Ltd.) and 16% mineral wool fiber (specification: particle diameter ≤ 30mm, produced by Langfang Qiyuan Refractory and Energy-saving Materials Co., Ltd.). In the main fiber material, add crystalline cellulose (model HW325, produced by So Chemical Co., Ltd. in Henan Province) that accounts for 0.2% of the dry main fiber material weight, and add 0.4% nanometer calcium carbonate (model MCA3000, Shanghai Zhizhen Chemical Co., Ltd.) and 0.8% magnesium hydroxide (model: TIGER-B15, produced by Dongguan Daoer Chemical Co., Ltd.),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com