Thermal electronic surface emitting source for vacuum system

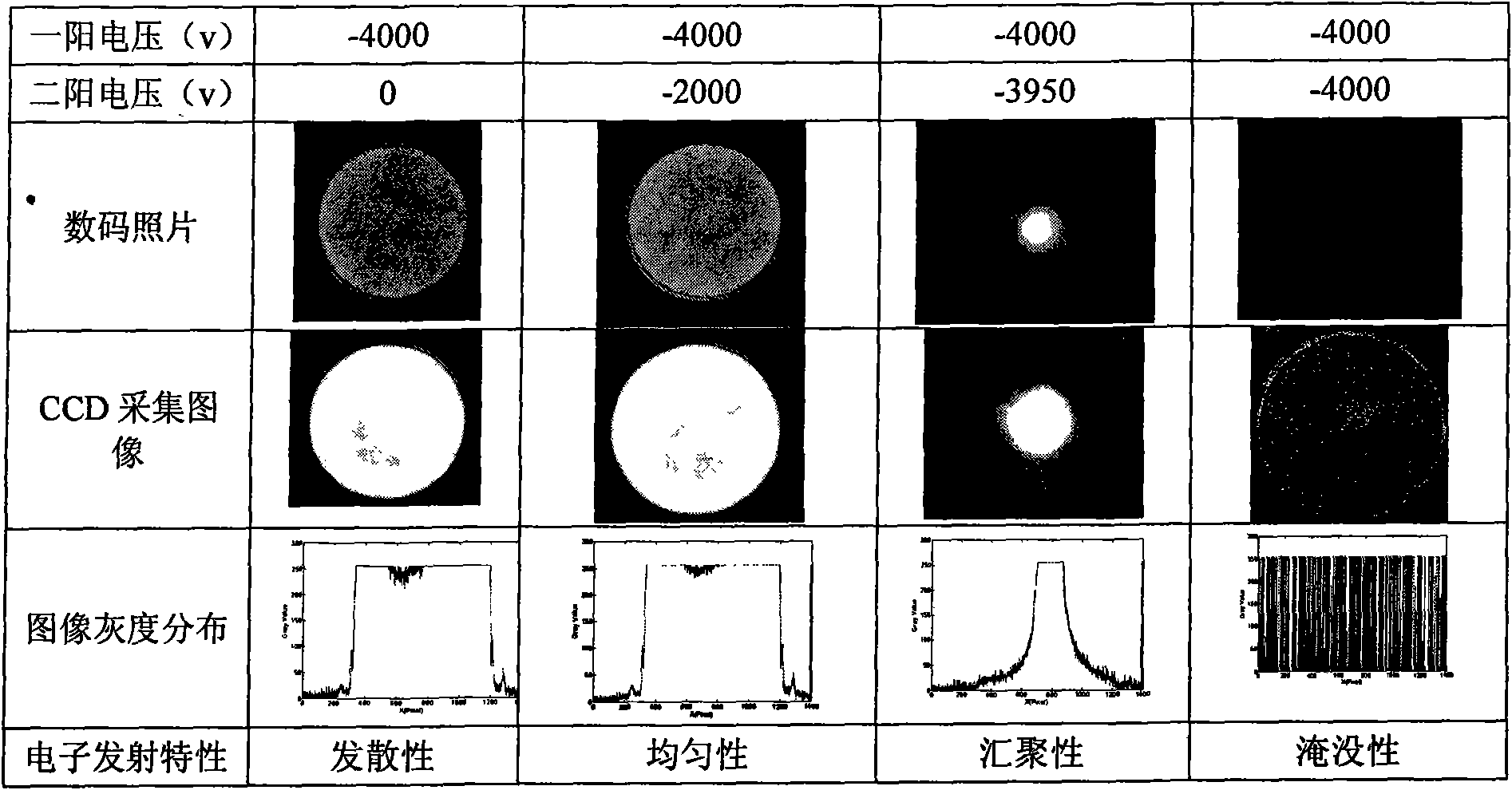

A vacuum system and electronic surface technology, applied in the direction of measurement/testing and testing optical properties in the manufacturing process, can solve the problems of non-uniformity, many centers, and the inability to detect the luminous efficiency and afterglow of the fluorescent screen, etc., and achieve a simple structure , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

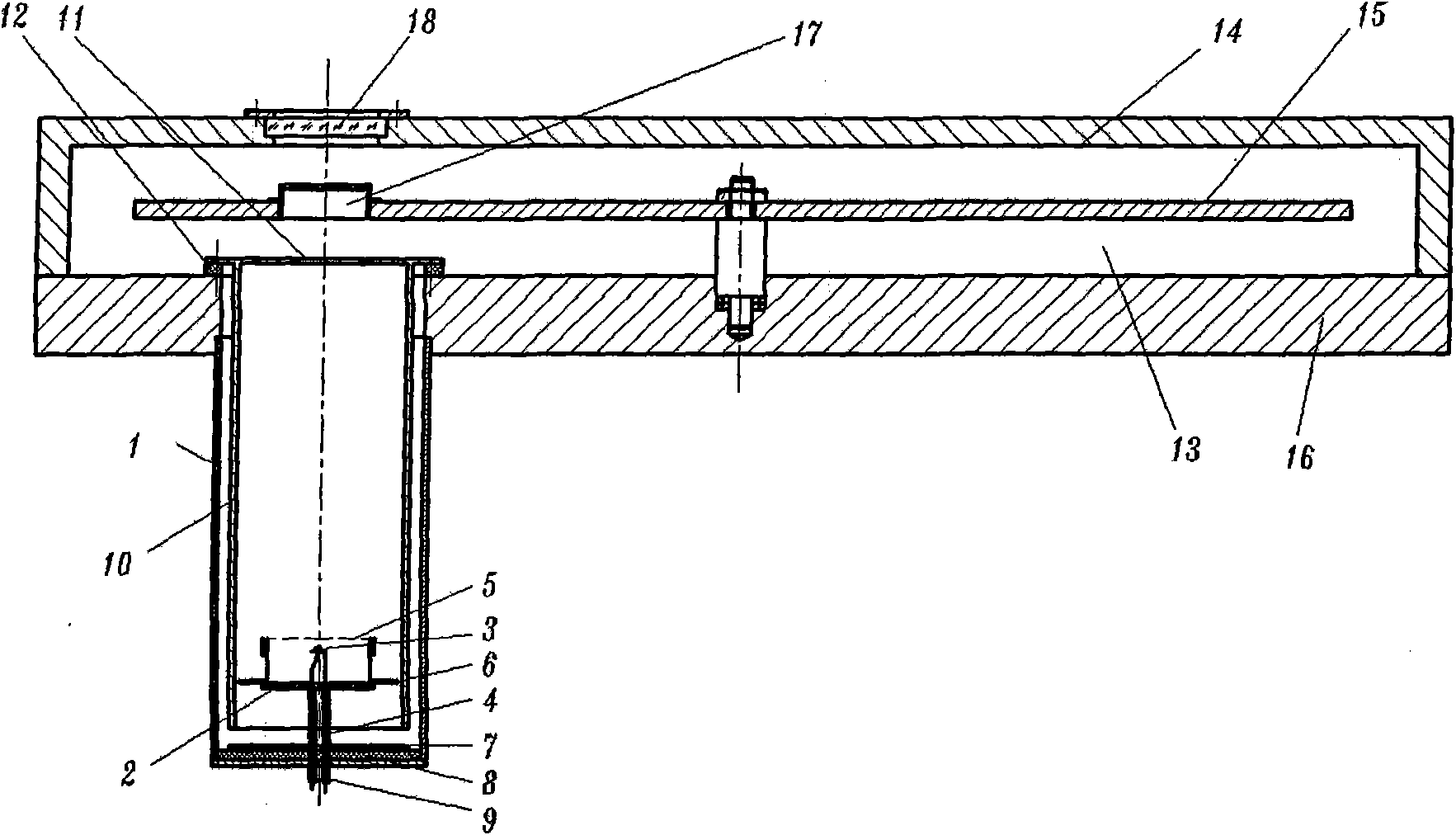

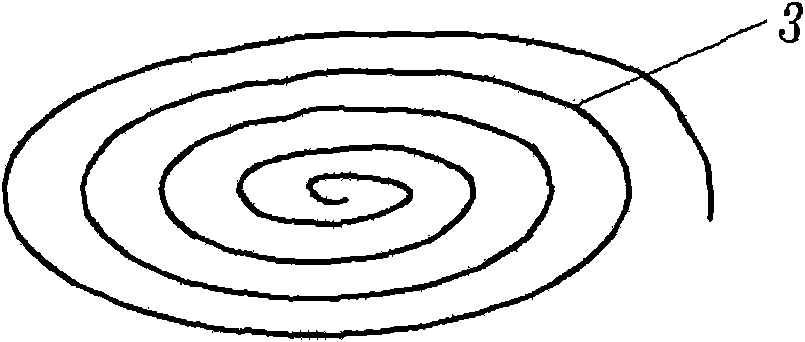

[0012] combine figure 1 , the thermionic surface emission source in the vacuum system that makes according to the present invention, it is made of shell 1, lamp holder 2, filament 3, filament terminal post 4, electron scattering net 5, terminal post frequency shielding disc 6, base frequency shielding disc 7 and a sleeve 10; the material of the shell 1 is stainless steel, the potential is 0V, and it is welded at the test port of the chassis 16 of the vacuum chamber. The bottom cover of the shell 1 is provided with an insulating disc 8, and the base frequency shield is placed on the insulating disc 8. Disc 7, base frequency shielding disc 7 is insulated from the bottom cover of heat shell 1; lamp holder 2 is made of stainless steel, 15mm high, 32mm in diameter, and filament 3 is placed inside. Filament 3 is tantalum wire with a diameter of 0.3mm, according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com