Evaporation technique for liquid sulfur trioxide

A liquid sulfur trioxide, sulfur trioxide technology, applied in sulfur trioxide/sulfuric acid, evaporation, chemical instruments and methods, etc., can solve the problems of equipment maintenance, difficult cleaning, danger, pipeline blockage, etc., to prevent The effect of generation and deposition, not easy to block the pipeline, and slowing down the corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

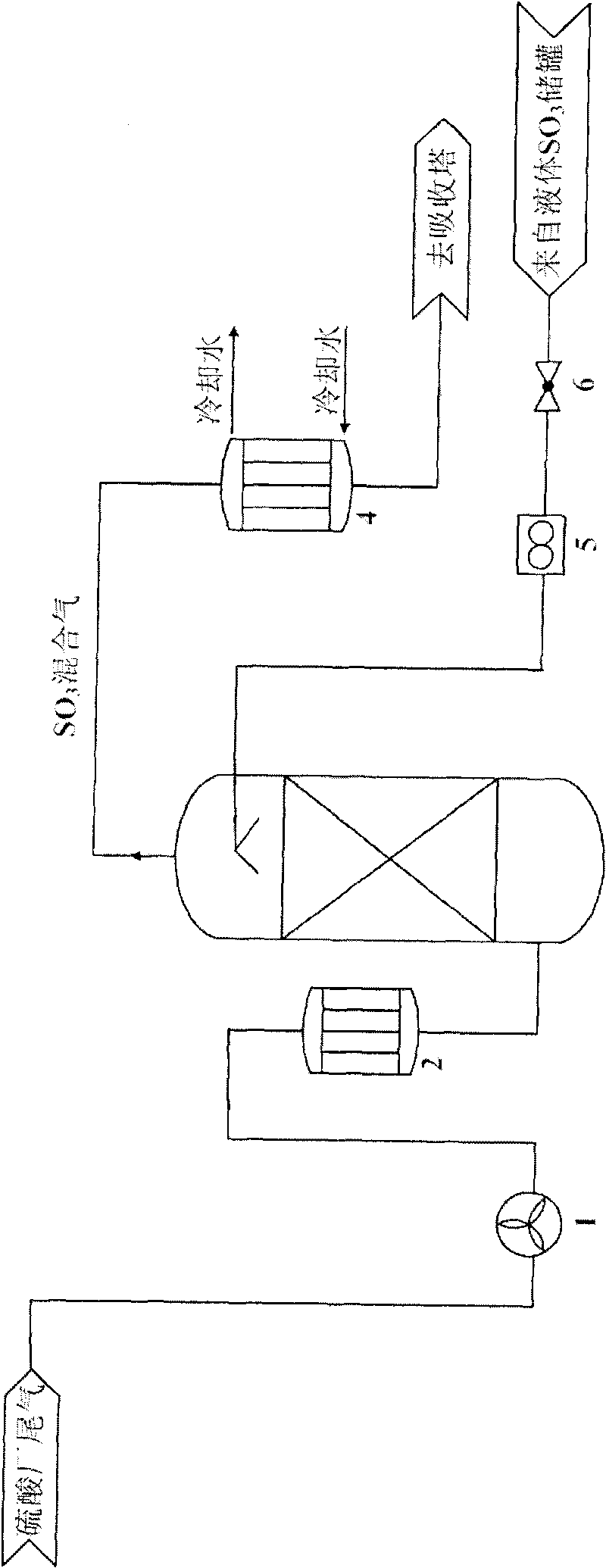

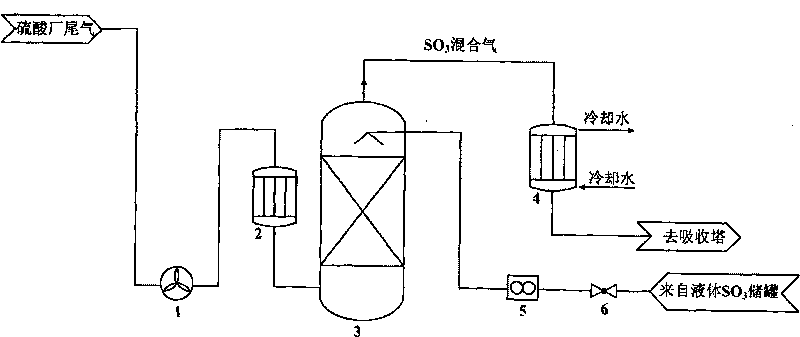

[0028] refer to figure 1 Start the Roots blower 1 to introduce (introduce through the second pipeline) the exhaust gas after filtering and drying from the sulfuric acid plant. The frequency of the Roots blower motor is first set to 20%, then observe the outlet pressure of the blower, and gradually increase the motor frequency to the normal value of about 75 %, at this time the air volume is 3525m 3 / h, the pressure is 55.0kPa, slowly open the steam valve of heater 2 to heat the process air, and the temperature of the process air at the outlet of the heater reaches 105.4°C. through liquid SO 3 The two nitrogen inlet and outlet regulating valves of the storage tank stabilize the pressure in the tank at 0.25-0.35Mpa; when using, open the liquid SO 3 storage tank to SO 3 Adjust the valve on the evaporator pipeline (the first pipeline), and then set the liquid SO 3 The flow rate is 623Kg / h, and then open the regulating valve (usually a pneumatic ball valve), using liquid SO 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com