Lost Foam Casting Using High Performance Coating Negative Pressure Combustion Empty Shell Pouring Flow Velocity Cold Elimination of Carbon Defects

A technology of lost foam casting and negative pressure combustion, which is applied to casting molding equipment, casting molds, and casting mold components, etc. It can solve problems such as easy lifting of molten steel or bulging mold shells, poor operational reliability, and easy to break and crack. Achieve the effects of easy separation and peeling, improved mechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

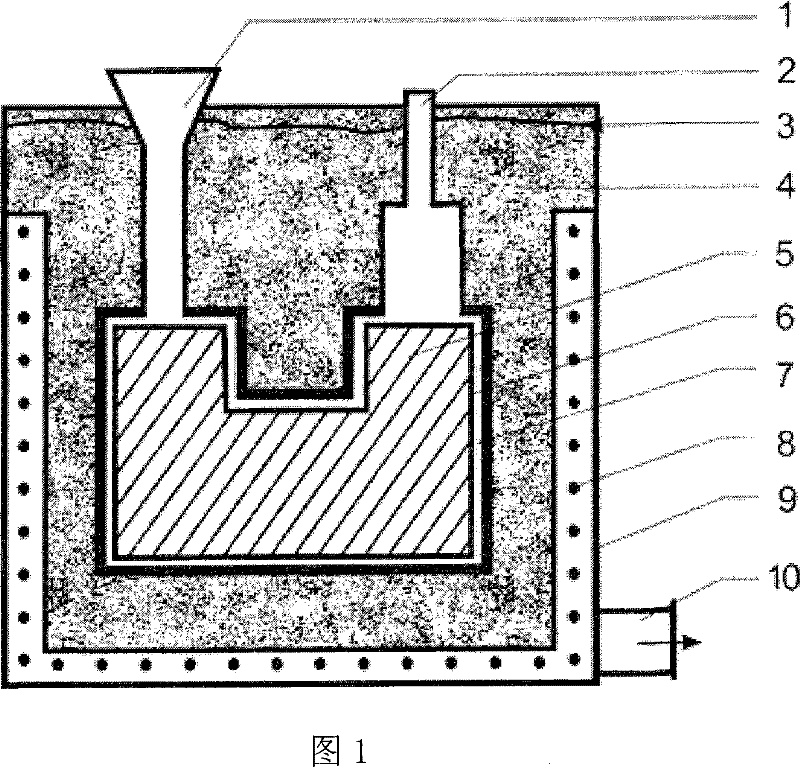

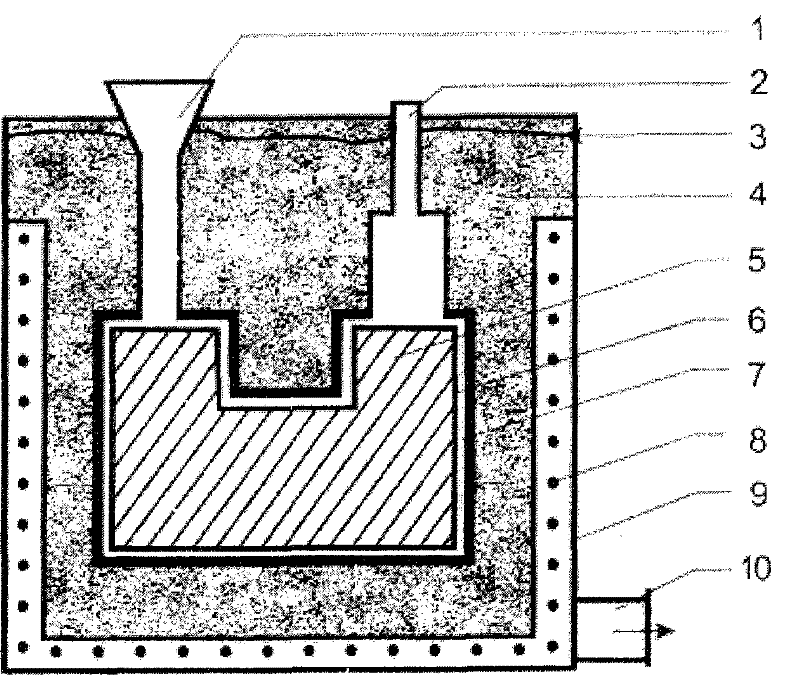

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not to limit the content of the present invention.

[0029] The method of eliminating carbon defects in castings by casting empty shells after negative pressure combustion of high-performance coatings and cooling them with air flow velocity includes the following steps:

[0030] (1) Prepare foam pattern 5;

[0031] (2) Paint the prepared high-performance (high-strength, high-breathability, fire-resistant, high-temperature cracking-resistant) paint shell 6 on the pattern, with a thickness > 1.5mm;

[0032] (3) Put the above-mentioned foam mold in the sand box, leave the gate 1 and the riser 2, fill it with dry sand 4, and seal it with a plastic film 3 on the dry sand surface;

[0033] (4) Start the vacuum pump (exhaust air), when the negative pressure is -40 ~ -80Kpa, ignite the foam pattern 5 from the gate 1 and the riser 2, burn and gasify,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com