Formula and low-temperature manufacturing method of a high-purity alumina hollow sphere product

A technology of alumina hollow spheres and high-purity alumina, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of not meeting the requirements of high temperature use, reducing the service life of firing equipment, and not saving energy in the manufacturing process. Achieve good heat insulation effect, improve service life, and use high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

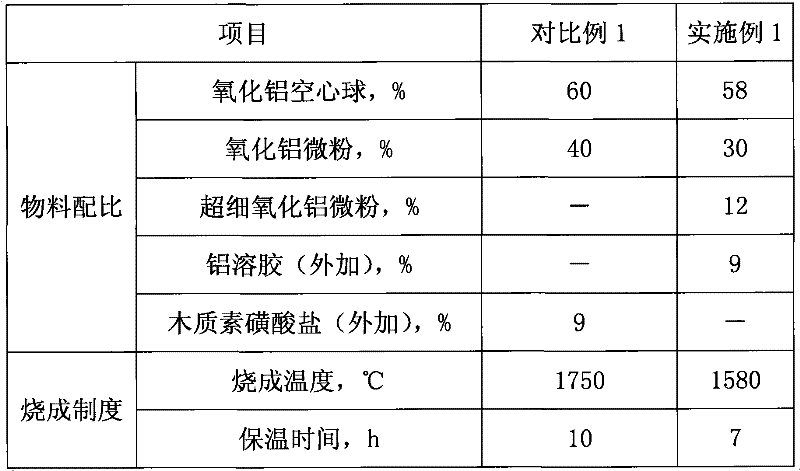

[0016] Example 1: Using the production process and technical scheme described in the present invention, the oxidation content of the alumina hollow spheres is 99.2%, the particle size is 0.2-4mm, and the natural bulk density is 0.78g / cm 3 aluminum; alumina micropowder alumina content is 99.5%, the particle size is 30μm; superfine alumina micropowder alumina content is 99.4%, the particle size is 0.96μm; aluminum sol binder colloidal particle diameter distribution is 5 ~ 30nm ; The concentration of lignosulfonate aqueous solution is 30%. The materials are uniformly mixed by a high-speed mixer according to the proportion, put into the mold cavity, formed by vibration and pressure, fully dried and then fired to produce high-purity alumina hollow ball products. The material of embodiment 1 and comparative example 1 is shown in the following table according to proportioning, firing system and product performance:

[0017]

[0018]

Embodiment 2

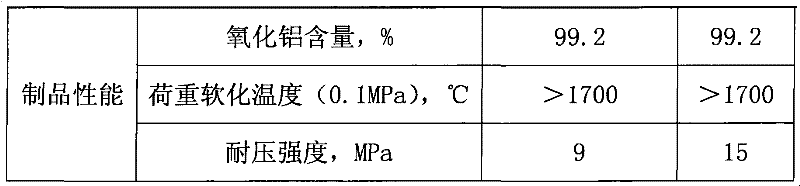

[0019] Example 2: Using the production process and technical scheme described in the present invention, the oxidation content of the alumina hollow spheres is 99.1%, the particle size is 0.2-3mm, and the natural bulk density is 0.86g / cm 3 aluminum; alumina micropowder alumina content is 99.3%, medium particle size is 31μm; superfine alumina micropowder alumina content is 99.4%, medium particle size is 0.71μm; aluminum sol binder colloidal particle diameter distribution is 5-25nm ; The concentration of lignosulfonate aqueous solution is 30%. The materials are uniformly mixed by a high-speed mixer according to the proportion, put into the mold cavity, formed by vibration and pressure, fully dried and then fired to produce high-purity alumina hollow ball products. The material of embodiment 2 and comparative example 2 is shown in the following table according to proportioning, firing system and product performance:

[0020]

Embodiment 3

[0021] Example 3: Using the production process and technical scheme described in the present invention, the oxidation content of the alumina hollow spheres is 99.3%, the particle size is 0.2-5mm, and the natural bulk density is 0.69g / cm 3 aluminum; alumina micropowder alumina content is 99.5%, medium particle size is 30μm; superfine alumina micropowder alumina content is 99.4%, medium particle size is 1.21μm; aluminum sol binder colloidal particle diameter distribution is 5-30nm ; The concentration of lignosulfonate aqueous solution is 30%; the concentration of polyvinyl alcohol aqueous solution is 6%. The materials are uniformly mixed by a high-speed mixer according to the proportion, put into the mold cavity, formed by vibration and pressure, fully dried and then fired to produce high-purity alumina hollow ball products. The material of embodiment 3 and comparative example 3 is shown in the following table according to proportioning, firing system and product performance:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com