Method for preparing gold-silver alloy nanoparticles in polyelectrolyte multilayer film

A technology of polyelectrolyte and gold-silver alloy, applied in the field of preparing gold-silver alloy nanoparticles, achieving high application value and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

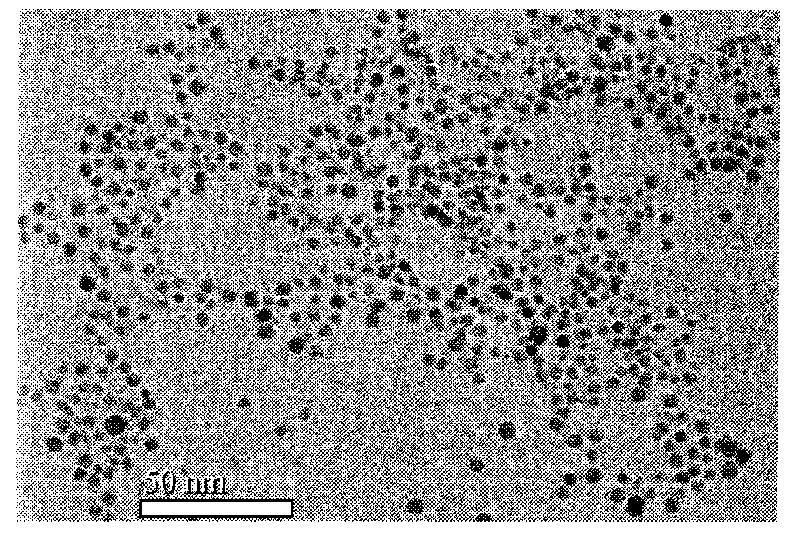

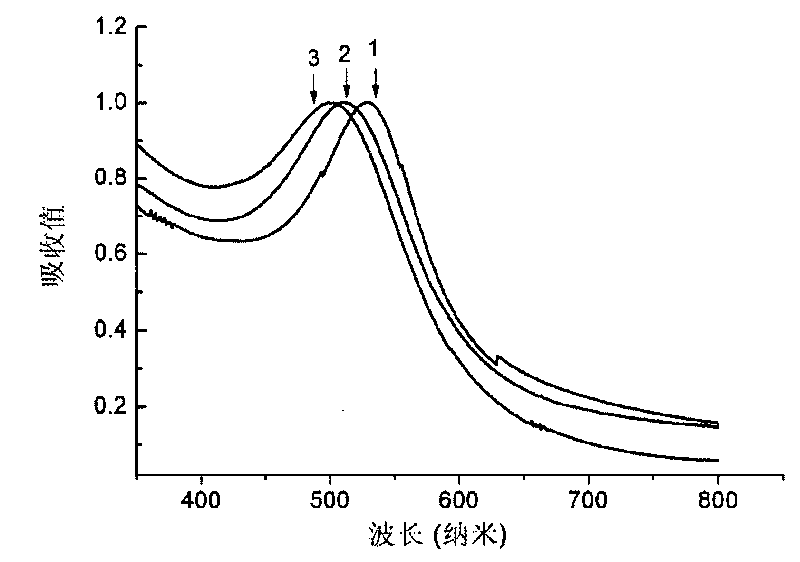

Image

Examples

Embodiment 1

[0014] 1) After immersing the glass sheet in a mixed solution of 98% sulfuric acid with a mass percentage of 7:3 and 30% hydrogen peroxide at a volume ratio of 7:3 for 30 minutes, rinse the glass sheet with pure water;

[0015] 2) Soak the glass sheet treated in step 1) in an aqueous solution of branched polyethyleneimine with a pH of 7.0 and a concentration of 5 mg / ml for 10 minutes, and rinse with pure water;

[0016] 3) Then, soak the glass sheet in step 2) in a polyacrylic acid solution with a pH of 3.5 and a concentration of 5 mg / ml for 10 minutes, and then rinse it with pure water;

[0017] 4) repeating step 2) and step 3) to obtain a polyelectrolyte multilayer film whose double-layer number of polyelectrolyte is 7;

[0018] 5) the polyelectrolyte multilayer membrane with the number of double layers that step 4) obtains is 2.0 at pH, and the aqueous solution of the chloroauric acid of 5mM is soaked for 15 minutes, rinses clean with pure water; Soak in the silver aqueous...

Embodiment 2

[0020] 1) After immersing the glass sheet in a mixed solution of 98% sulfuric acid with a mass percentage of 7:3 and 30% hydrogen peroxide at a volume ratio of 7:3 for 30 minutes, rinse the glass sheet with pure water;

[0021] 2) Soak the glass sheet treated in step 1) in an aqueous solution of branched polyethyleneimine with a pH of 9.0 and a concentration of 5 mg / ml for 10 minutes, and rinse with pure water;

[0022] 3) Then soak the glass sheet in a polyacrylic acid solution with a pH of 3.0 and a concentration of 5 mg / ml for 10 minutes, and then rinse it with pure water;

[0023] 4) repeating step 2) and step 3) to obtain a polyelectrolyte multilayer film whose double-layer number of polyelectrolyte is 7;

[0024] 5) the polyelectrolyte multilayer membrane that the double-layer number that step 4) is obtained is 2.5 at pH, and the aqueous solution of chloroauric acid that concentration is 5mM soaks 15 minutes, rinses clean with pure water; Then concentration is 10mM nitri...

Embodiment 3

[0026] 1) After immersing the glass sheet in a mixed solution of 98% sulfuric acid with a mass percentage of 7:3 and 30% hydrogen peroxide at a volume ratio of 7:3 for 30 minutes, rinse the glass sheet with pure water;

[0027] 2) Soak the glass sheet treated in step 1) in an aqueous solution of branched polyethyleneimine with a pH of 5.0 and a concentration of 5 mg / ml for 10 minutes, and rinse with pure water;

[0028] 3) Soak the glass sheet in a polyacrylic acid solution with a pH of 7.0 and a concentration of 5 mg / ml for 10 minutes, and then rinse it with pure water;

[0029] 4) repeat step 2) and step 3) to obtain the polyelectrolyte multilayer film that the double layer number of polyelectrolyte is 5;

[0030] 5) the polyelectrolyte multilayer membrane that the double-layer number that step 4) is obtained is 3.0 at pH, and the aqueous solution that concentration is the chloroauric acid of 5mM soaks 15 minutes, rinses clean with pure water; Then concentration is 10mM nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com