Raw material formulation of high-gradient non-linear resistance card and manufacturing method thereof

A technology of non-linear resistors and manufacturing methods, applied in the direction of resistor manufacturing, resistors, varistors, etc., can solve the problems that cannot fully meet the requirements of ultra-high voltage transmission and distribution arrester equipment, and achieve space volume reduction, reduce environmental pollution, The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present embodiment adopts the raw material formula of the high-gradient non-linear resistor sheet, and its molar percentage composition is: wherein Bi 2 o 3 : 0.5-1.5%, Co 2 o 3 : 0.7-1.2%, MnCO 3 : 0.4-0.9%, Sb 2 o 3 : 0.7-1.5%, Cr 2 o 3 : 0.2-0.8%, SiO 2 : 0.5-1.1%, Y 2 o 3 0.3-1.2% additives; the balance is mainly ZnO.

[0018] In this embodiment, the manufacturing method is carried out according to the raw material formula of the above-mentioned high-gradient non-linear resistance sheet, which specifically includes the following steps:

[0019] First, weigh the components of the additive and the main material ZnO, then mix the components of the additive through ball milling, heat and dry them, put them into a ceramic sagger, calcine at 800°C for 1 hour, cool naturally, and pulverize to form fine additive powder ;

[0020] Secondly, add additive powder, main material ZnO, organic binder-polyvinyl alcohol (PVA), polyacrylate ammonium dispersant, water...

Embodiment 2

[0029] The present embodiment adopts the raw material formula of the high-gradient non-linear resistor sheet, and its molar percentage composition is: wherein Bi 2 o 3 : 0.5-1.5%, Co 2 o 3 : 0.7-1.2%, MnCO 3 : 0.4-0.9%, Sb 2 o 3 : O.7-1.5%, Cr 2 o 3 : 0.2-0.8%, SiO 2 : 0.5-1.1%, Y 3 o 3 0.3-1.2% additives; the balance is mainly ZnO.

[0030] In this embodiment, the manufacturing method is carried out according to the raw material formula of the above-mentioned high-gradient non-linear resistance sheet, which specifically includes the following steps:

[0031] First, weigh the components of the additive and the main material ZnO, then mix the components of the additive through ball milling, heat and dry them, put them into a ceramic sagger, calcine at 800°C for 1 hour, cool naturally, and pulverize to form fine additive powder ;

[0032] Secondly, in the mixing tank, add additive powder, main material ZnO, organic binder, dispersant, water and Al(NO 3 ) 3 9H 2 O...

Embodiment 3

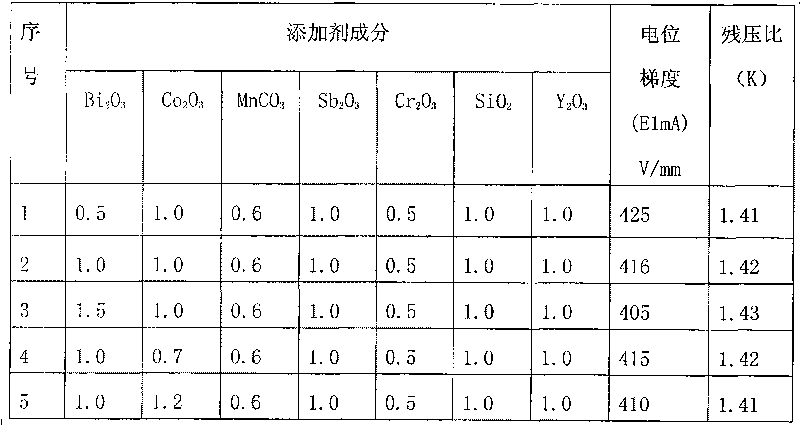

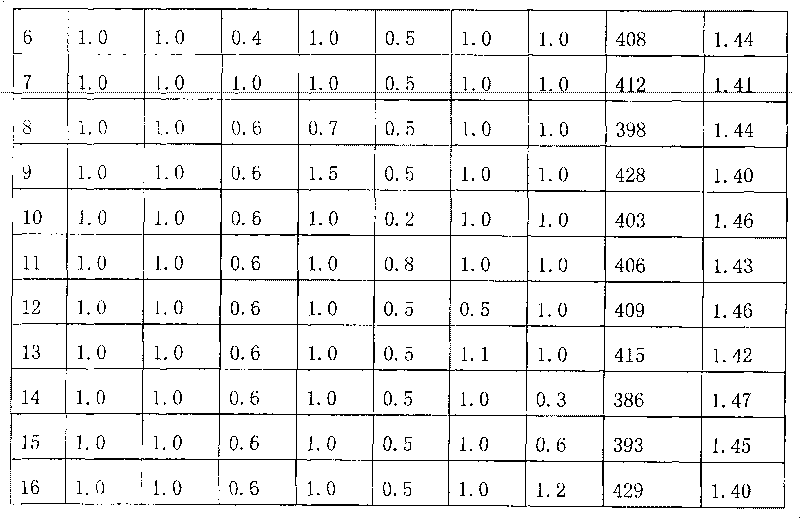

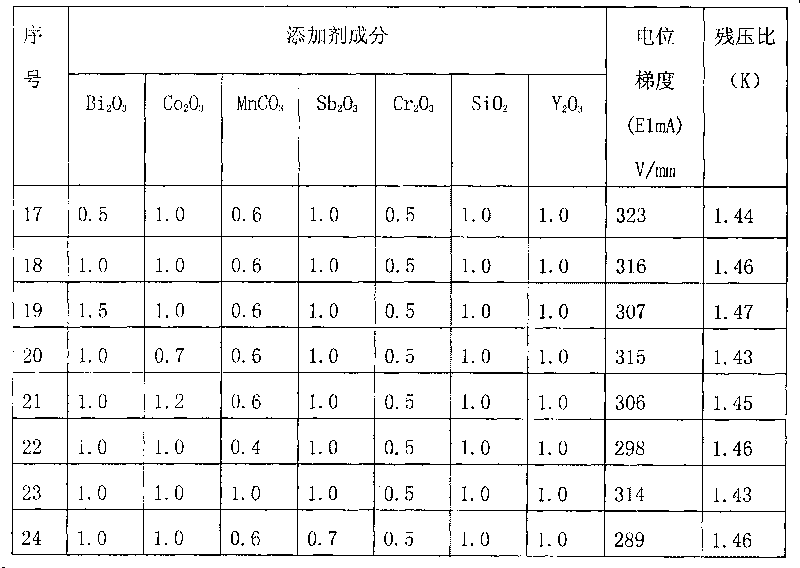

[0041] The present embodiment adopts the raw material formula of the high-gradient non-linear resistor sheet, and its molar percentage composition is: wherein Bi 2 o 3 : 1.0%, Co 2 o 3 : 1.0%, MnCO 3 : 0.6%, Sb 2 o 3 : 1.0%, Cr 2 o 3 : 0.5%, SiO 2 : 1.0%, Y 2 o 3 1.0%, the balance is mainly ZnO. In the manufacturing process of the resistor chip, the green body is a cylinder with a diameter of 36 mm to 126 mm and a height of 27 mm; after removing the organic binder and dispersant, it is sintered at 1100 ° C or 1200 ° C for 4 hours to obtain a resistor chip sintered body, and others The steps are the same as those in Examples 1 and 2, and the non-linear characteristics of the manufactured resistor sheet are measured, and the measurement results are shown in Table 3 and Table 4.

[0042] table 3:

[0043] serial number

[0044] Table 4:

[0045] serial number

[0046] serial number

[0047] It can be seen from Table 3 and Table 4 that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com