Preparation method of yttria-base transparent ceramics with designable component and structure

A technology of transparent ceramics and yttrium oxide is applied in the field of preparation of yttrium oxide-based transparent ceramics, and can solve the problems of flammability, harm, difficulty in preparing complex shapes and gradient doping of organic solvents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

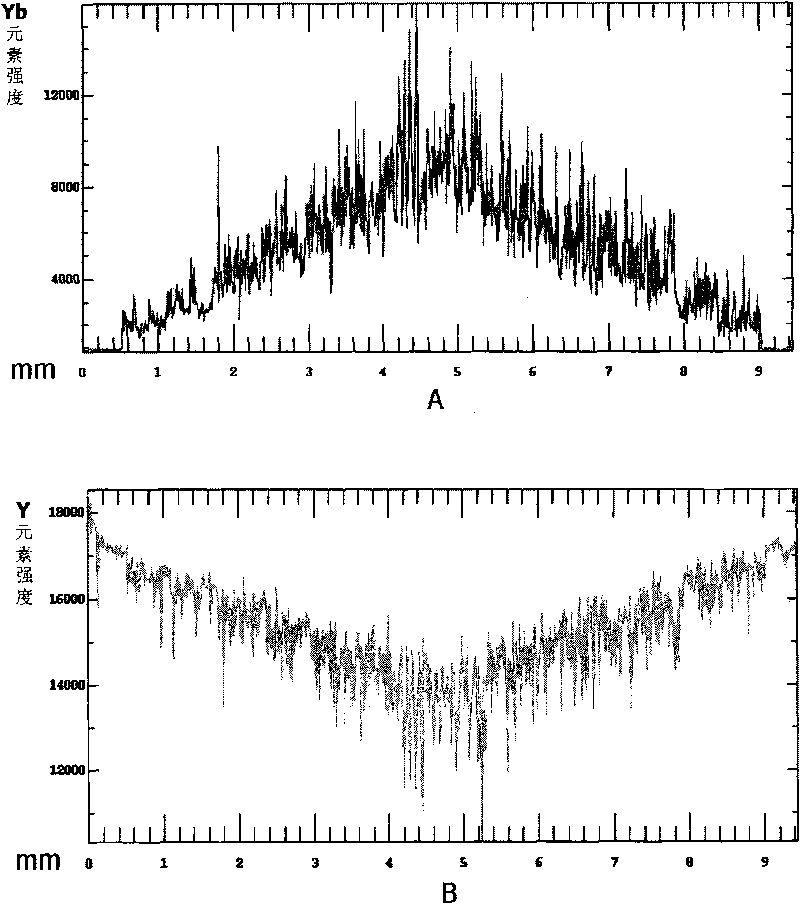

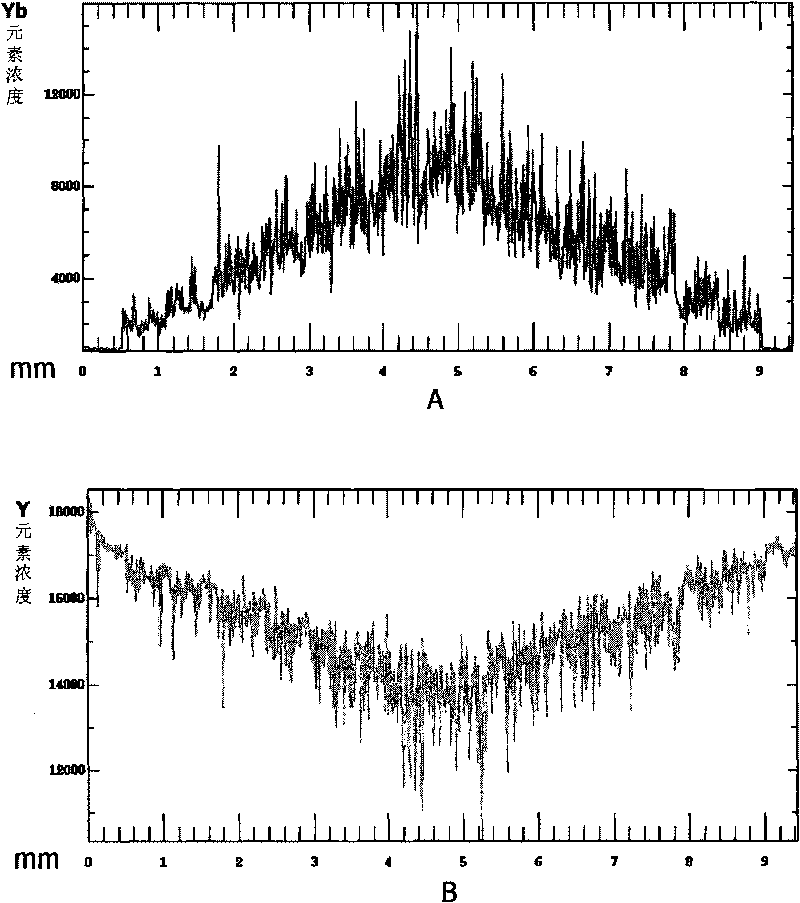

[0045] 50g of ytterbium oxide-doped yttrium oxide-based mixed powder (in each batch, based on the sum of the number of moles of ytterbium element and the sum of the number of moles of yttrium element, the molar concentrations of ytterbium element are respectively: 0%, 1%, 2 %, 3%, 4%, 5%, 6%, 7%, 8%) and 1g CE64 (polymethacrylic acid dispersant) were added to 10g water, ball milled for 8h to prepare a slurry with a solid content of 47vol%. Then add 6g of DM765 (styrene binder), after ball milling for 3 hours, remove air bubbles, cast to form a film, the thickness of the cast film is 0.8mm.

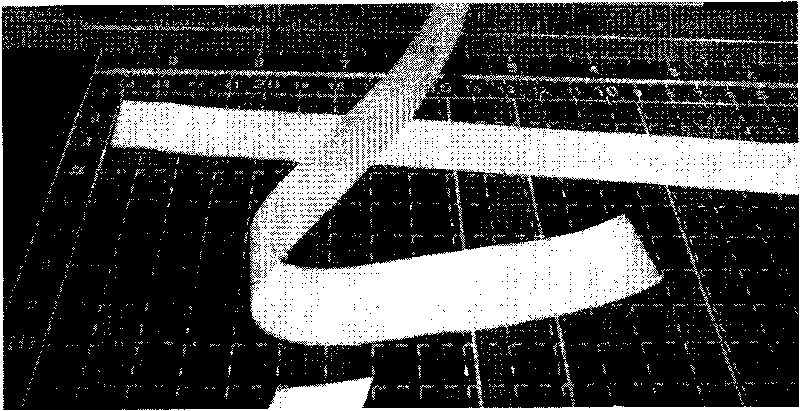

[0046] Process cast films with different contents into rectangles (3cm in width and 4cm in length), and then cast films with different doping concentrations, the doping concentration of each cast film from top to bottom is 0% / 1% / 2% / 3% / 4% / 5% / 6% / 7% / 8% / 7% / 6% / 5% / 4% / 3% / 2% / 1% / 0% design , stacked layer by layer. The laminated samples were cold isostatically pressed under a pressure of 200MPa, ...

Embodiment 2

[0049] 55g of ytterbium oxide-doped yttrium oxide-based mixed powder (in each batch, based on the sum of the number of moles of ytterbium element and the sum of the number of moles of yttrium element, the molar concentrations of ytterbium element are respectively: 0%, 2%, 4 %, 6%, 8%) and 0.8g of 731A (polycarboxylic acid dispersant) were added into 10g of water, and ball milled for 10h to form a slurry with a volume solid content of 49vol%. Then add 10g of Tongyang Chemical 4700 emulsion (binder), after ball milling for 3 hours, remove air bubbles, cast to form a film, the thickness of the cast film is 1mm.

[0050] Process cast films with different contents into rectangles (3cm in width and 4cm in length), and then cast films with different doping concentrations, the doping concentration of each cast film from top to bottom is 0% / 2% / 4% / 6% / 8% / 6% / 4% / 2% / 0% design, layer by layer. The laminated samples were cold isostatically pressed under a pressure of 250Mpa, and then heated...

Embodiment 3

[0053] The mixed powder of 35g neodymium oxide doped yttrium oxide base (in each batch, with the sum of the molar number of neodymium element and the molar number of yttrium element, the molar concentration of neodymium element is respectively 0%, 0.4%, 0.8% , 1.2%, 1.6%) and 0.7g PE1168 (dibutyl phthalate organic dispersant) were added to 8g butanone-ethanol mixed solution (3:1), ball milled for 10h, and then 5gPVB (organic binder) was added , after ball milling for 3 hours, the casting film was formed, and the thickness of the casting film was 0.4mm.

[0054] Process the cast film with different contents into a rectangle (2cm in width and 6cm in length), and then design according to 0% / 1.6% / 0.8% / 0% / 0.4% / 0.8% / 1.2% / 1.6% / 0% The scheme is stacked. The laminated samples were cold isostatically pressed under a pressure of 150MPa, and then heated to 600°C in a muffle furnace at a speed of 2°C / min for one hour for debonding. After debonding, the sample was cold isostatically press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com