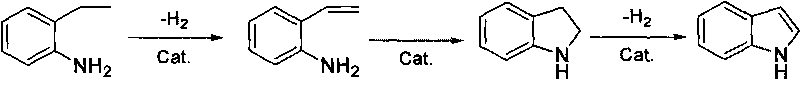

Method for preparing indole by oxidative dehydrogenation of o-ethylaniline

A technology of o-ethylaniline and oxidative dehydrogenation, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve industrial application limitations, catalyst conversion rate and selectivity reduction , carbon on the surface of the catalyst, etc., to achieve the effect of convenient operation and reduction of reduction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

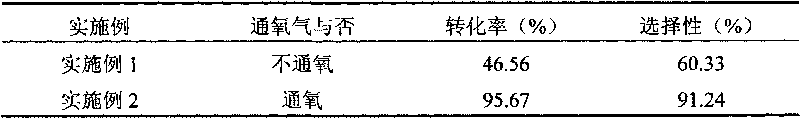

[0017] In the dehydrogenation reactor, fill 20 grams of boroaluminate copper catalysts, vaporize after o-ethylaniline and water are mixed and enter the fixed-bed reactor for reaction, the reaction temperature is 640 ° C, and the volume ratio of o-ethylaniline and water is 1: 6. The hourly space velocity of o-ethylaniline feed liquid is 0.1h -1 , After 200 h of normal pressure reaction, the conversion rate of o-ethylaniline and the selectivity of indole were measured, and the results are shown in Table 1.

Embodiment 2

[0019] Identical to the method of Example 1, the difference is that o-ethylaniline and water are mixed and then vaporized and then mixed with preheated air to enter the fixed-bed reactor for reaction. The mol ratio of o-ethylaniline and the oxygen in the air is 1:1, normal pressure reaction 200h after the measurement of o-ethylaniline conversion rate and indole selectivity, the results are shown in Table 1.

[0020] Table 1

[0021]

Embodiment 3

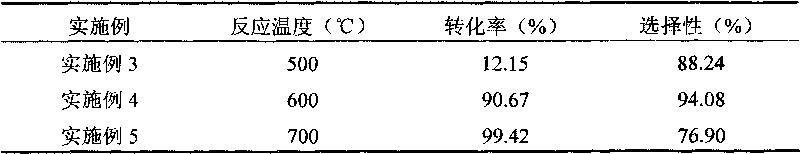

[0023] In the dehydrogenation reactor, fill 20 grams of copper boroaluminate catalyst, o-ethylaniline and water are mixed, vaporized and then mixed with preheated air, then enter the fixed bed reactor for reaction, the reaction temperature is 500 ° C, normal pressure, The volume ratio of o-ethylaniline and water is 1:6, the molar ratio of o-ethylaniline and oxygen is 1:1, and the hourly space velocity of o-ethylaniline liquid is 0.1h -1 , and the reaction results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com