Long afterglow rare earth phosphor and polymer composite material

A technology of rare earth luminescence and composite materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low afterglow brightness, poor chemical stability, and short time, and achieve the effects of long afterglow time, good stability, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

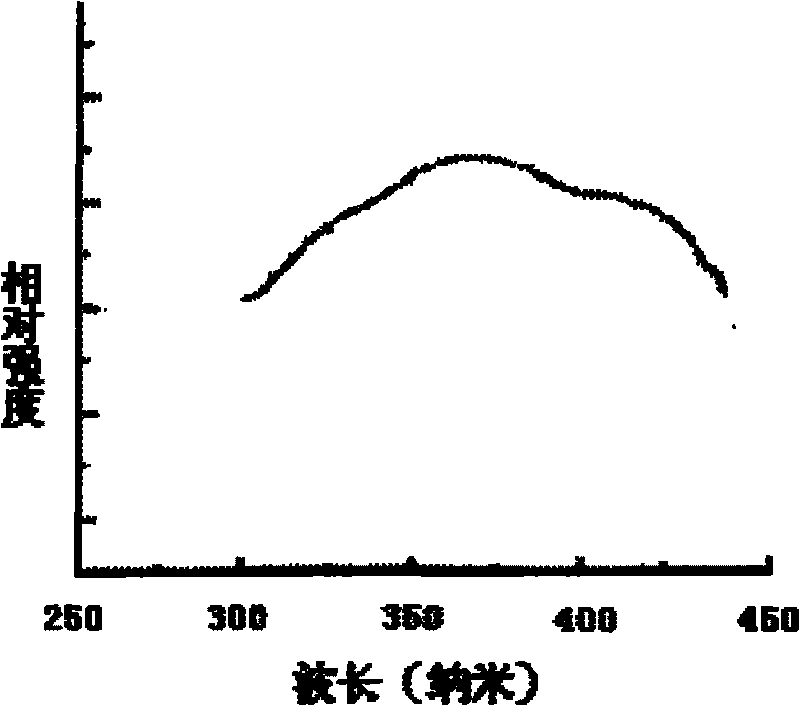

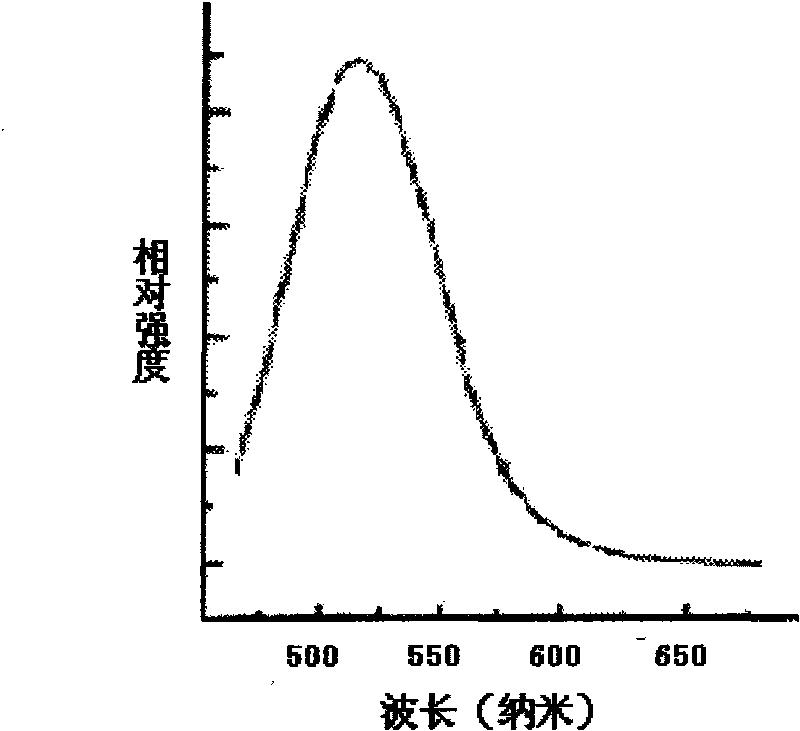

Image

Examples

Embodiment 1

[0016] Example 1 The specific proportions of the long-lasting rare earth luminescent powder polymer composite material in parts by weight are: 15 parts of green long-lasting rare earth luminescent powder, 80 parts of high-density polyethylene (HDPE), 0.5 part of zinc stearate, antioxidant Agent (1010) 0.5 parts, paraffin 4 parts, castor oil 1 part.

[0017] Preparation method: According to the ratio, the above materials are extruded and granulated by twin-screw extruder, and the head temperature of the twin-screw extruder is 180°C.

Embodiment 2

[0019] The specific ratio of the long afterglow rare earth luminescent powder polymer composite material in parts by weight is:

[0020] 20 parts of green long-lasting rare earth luminescent powder, 75 parts of low-density polyethylene (LDPE), 1 part of zinc stearate, 1 part of antioxidant (1010), 3 parts of paraffin, and 1 part of castor oil.

[0021] Preparation method: According to the ratio, the above-mentioned materials are extruded and granulated by twin-screw extruder, and the head temperature of the twin-screw extruder is 160°C.

Embodiment 3

[0023] The specific ratio of the long afterglow rare earth luminescent powder polymer composite material in parts by weight is:

[0024] 30 parts of green long-lasting rare earth luminescent powder, 66 parts of ethylene vinyl acetate copolymer (EVA), 1 part of zinc stearate, 1 part of antioxidant (1010), 2 parts of paraffin, and 2 parts of castor oil.

[0025] Preparation method: According to the ratio, the above materials are extruded and granulated by twin-screw extruder, and the head temperature of the twin-screw extruder is 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com